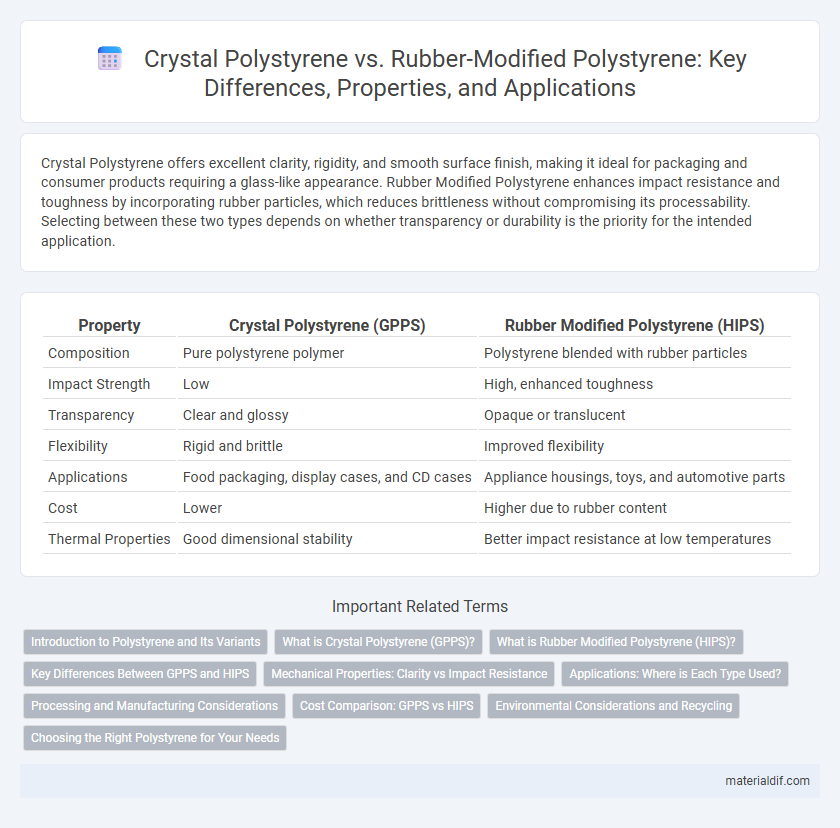

Crystal Polystyrene offers excellent clarity, rigidity, and smooth surface finish, making it ideal for packaging and consumer products requiring a glass-like appearance. Rubber Modified Polystyrene enhances impact resistance and toughness by incorporating rubber particles, which reduces brittleness without compromising its processability. Selecting between these two types depends on whether transparency or durability is the priority for the intended application.

Table of Comparison

| Property | Crystal Polystyrene (GPPS) | Rubber Modified Polystyrene (HIPS) |

|---|---|---|

| Composition | Pure polystyrene polymer | Polystyrene blended with rubber particles |

| Impact Strength | Low | High, enhanced toughness |

| Transparency | Clear and glossy | Opaque or translucent |

| Flexibility | Rigid and brittle | Improved flexibility |

| Applications | Food packaging, display cases, and CD cases | Appliance housings, toys, and automotive parts |

| Cost | Lower | Higher due to rubber content |

| Thermal Properties | Good dimensional stability | Better impact resistance at low temperatures |

Introduction to Polystyrene and Its Variants

Polystyrene is a versatile synthetic aromatic polymer made from the monomer styrene, widely used in packaging, insulation, and consumer goods. Crystal polystyrene offers high clarity and rigidity, making it ideal for products requiring transparency and stiffness, such as food containers and optical devices. Rubber modified polystyrene incorporates rubber particles to enhance impact resistance and toughness, suited for applications like automotive parts and durable housings.

What is Crystal Polystyrene (GPPS)?

Crystal Polystyrene (GPPS) is a clear, rigid thermoplastic characterized by its excellent transparency, high gloss, and good dimensional stability, making it ideal for applications requiring aesthetic appeal and precision. It differs from Rubber Modified Polystyrene (HIPS) by lacking added rubber particles, resulting in higher brittleness but improved clarity and surface finish. GPPS is commonly used in consumer goods packaging, disposable cutlery, and laboratory ware due to its ease of molding and attractive appearance.

What is Rubber Modified Polystyrene (HIPS)?

Rubber Modified Polystyrene, also known as High Impact Polystyrene (HIPS), is a type of polystyrene enhanced with rubber particles to improve its toughness and impact resistance. Unlike Crystal Polystyrene, which is rigid and brittle, HIPS offers greater flexibility and durability, making it suitable for applications requiring higher mechanical strength such as appliance housings and consumer electronics. The incorporation of rubber modifies the polymer matrix, resulting in a material that balances rigidity with impact absorption properties.

Key Differences Between GPPS and HIPS

Crystal Polystyrene (GPPS) offers high clarity, rigidity, and ease of processing, making it ideal for transparent applications such as food packaging and optical products. Rubber Modified Polystyrene (HIPS) incorporates rubber particles to enhance impact resistance and toughness, which is essential for consumer goods that require durability, like appliance housings and toys. The key differences between GPPS and HIPS lie in their mechanical properties: GPPS provides stiffness and clarity, while HIPS delivers superior impact strength and toughness due to its rubber modification.

Mechanical Properties: Clarity vs Impact Resistance

Crystal Polystyrene exhibits high clarity with excellent stiffness, making it ideal for applications requiring transparency and dimensional stability. Rubber Modified Polystyrene enhances impact resistance significantly by incorporating rubber particles, improving toughness while sacrificing some optical clarity. The mechanical trade-off positions Crystal Polystyrene for aesthetic uses and Rubber Modified Polystyrene for more durable, impact-prone environments.

Applications: Where is Each Type Used?

Crystal Polystyrene is commonly used in packaging, disposable cutlery, and model making due to its clarity and rigidity, allowing for visually appealing and precise products. Rubber Modified Polystyrene finds applications in automotive parts, electrical housings, and impact-resistant consumer goods, where enhanced toughness and durability are critical. The choice between these materials depends on the required physical properties and end-use performance demands.

Processing and Manufacturing Considerations

Crystal polystyrene offers ease of processing through injection molding and extrusion with excellent dimensional stability and surface finish, making it ideal for precision applications. Rubber modified polystyrene requires adjusted processing conditions such as higher melt temperatures and slower cooling rates to accommodate improved impact resistance without compromising structural integrity. Manufacturers must carefully optimize molding parameters to balance the toughness of rubber modified polystyrene with its flow properties, ensuring efficient production and consistent product quality.

Cost Comparison: GPPS vs HIPS

General Purpose Polystyrene (GPPS), also known as Crystal Polystyrene, typically costs less than High Impact Polystyrene (HIPS), which is rubber modified for enhanced toughness. The addition of rubber in HIPS increases material costs due to more complex manufacturing processes and raw material expenses. GPPS is preferred in applications where clarity and lower cost are priorities, while HIPS justifies its higher price with improved impact resistance for more demanding uses.

Environmental Considerations and Recycling

Crystal Polystyrene (GPPS) and Rubber Modified Polystyrene (HIPS) differ significantly in environmental impact and recycling processes. GPPS is more easily recyclable due to its homogenous polymer structure, allowing for higher-quality recycled material with less contamination. HIPS, containing rubber particles, complicates recycling by reducing the purity of recycled output and often requires specialized facilities to separate components, leading to increased environmental considerations.

Choosing the Right Polystyrene for Your Needs

Crystal Polystyrene offers excellent clarity and rigidity, making it ideal for packaging and optical applications where transparency is critical. Rubber Modified Polystyrene enhances impact resistance and toughness, suited for products requiring durability and flexibility such as appliance housings and automotive parts. Selecting between Crystal and Rubber Modified Polystyrene depends on balancing optical properties against mechanical strength for specific project requirements.

Crystal Polystyrene vs Rubber Modified Polystyrene Infographic

materialdif.com

materialdif.com