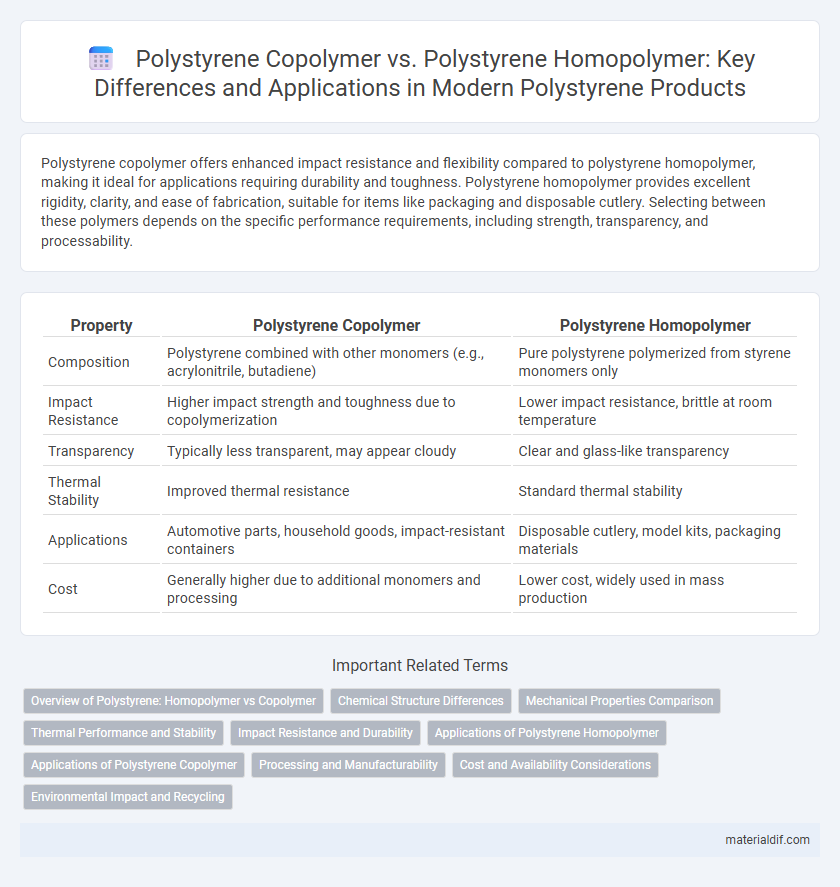

Polystyrene copolymer offers enhanced impact resistance and flexibility compared to polystyrene homopolymer, making it ideal for applications requiring durability and toughness. Polystyrene homopolymer provides excellent rigidity, clarity, and ease of fabrication, suitable for items like packaging and disposable cutlery. Selecting between these polymers depends on the specific performance requirements, including strength, transparency, and processability.

Table of Comparison

| Property | Polystyrene Copolymer | Polystyrene Homopolymer |

|---|---|---|

| Composition | Polystyrene combined with other monomers (e.g., acrylonitrile, butadiene) | Pure polystyrene polymerized from styrene monomers only |

| Impact Resistance | Higher impact strength and toughness due to copolymerization | Lower impact resistance, brittle at room temperature |

| Transparency | Typically less transparent, may appear cloudy | Clear and glass-like transparency |

| Thermal Stability | Improved thermal resistance | Standard thermal stability |

| Applications | Automotive parts, household goods, impact-resistant containers | Disposable cutlery, model kits, packaging materials |

| Cost | Generally higher due to additional monomers and processing | Lower cost, widely used in mass production |

Overview of Polystyrene: Homopolymer vs Copolymer

Polystyrene homopolymer consists solely of styrene monomers, offering high rigidity, clarity, and ease of processing, making it suitable for applications like disposable cutlery and CD cases. Polystyrene copolymer incorporates additional monomers such as acrylonitrile or butadiene, enhancing impact resistance, thermal stability, and chemical resistance, which broadens its use in automotive parts and protective packaging. The choice between homopolymer and copolymer depends on the required mechanical properties and environmental conditions of the intended application.

Chemical Structure Differences

Polystyrene copolymers consist of styrene monomers polymerized with one or more different monomers, introducing varied functional groups and altering polymer chain architecture compared to polystyrene homopolymers, which are composed solely of styrene units. The incorporation of comonomers such as acrylonitrile or butadiene in copolymers creates copolymer blocks or random arrangements, enhancing properties like impact resistance and flexibility. Polystyrene homopolymers, with their uniform phenyl-substituted carbon backbone, exhibit higher rigidity and glass transition temperatures due to their consistent chemical structure.

Mechanical Properties Comparison

Polystyrene copolymer exhibits enhanced toughness and impact resistance compared to polystyrene homopolymer due to the incorporation of rubbery or other monomeric segments within its structure. The homopolymer tends to have higher stiffness and rigidity but is more brittle under stress. Mechanical testing shows that copolymers typically achieve higher elongation at break and improved impact strength, making them preferable for applications requiring durability and flexibility.

Thermal Performance and Stability

Polystyrene copolymers exhibit enhanced thermal performance and stability compared to polystyrene homopolymers due to the incorporation of comonomers that disrupt the polymer chain regularity, increasing thermal resistance. The glass transition temperature (Tg) of polystyrene copolymers is often higher or more controlled, allowing them to maintain structural integrity under elevated temperatures better than homopolymers. These properties make copolymers more suitable for applications requiring improved heat resistance and dimensional stability over traditional homopolymer polystyrene.

Impact Resistance and Durability

Polystyrene copolymer exhibits significantly higher impact resistance compared to polystyrene homopolymer due to its modified molecular structure incorporating rubbery copolymers. This enhanced toughness makes copolymer grades ideal for applications requiring durability and flexibility, such as protective packaging and automotive components. In contrast, polystyrene homopolymer offers greater rigidity and ease of processing but is more prone to brittleness and lower impact strength under stress.

Applications of Polystyrene Homopolymer

Polystyrene homopolymer is widely used in packaging materials, disposable cutlery, and insulation due to its rigidity, clarity, and ease of molding. Its applications extend to consumer products such as CD cases, plastic models, and laboratory ware, where dimensional stability and surface finish are critical. Homopolystyrene's brittleness limits its use in impact-resistant applications, which are better served by polystyrene copolymers.

Applications of Polystyrene Copolymer

Polystyrene copolymer exhibits enhanced impact resistance and flexibility, making it ideal for automotive parts, appliance housings, and protective packaging. Its improved chemical and thermal stability allows use in medical device components and food containers requiring durability and safety. Compared to polystyrene homopolymer, copolymers are preferred in demanding applications where toughness and performance are critical.

Processing and Manufacturability

Polystyrene copolymer offers enhanced impact resistance and flexibility compared to polystyrene homopolymer, making it more suitable for applications requiring greater toughness during processing. The copolymer's improved melt strength allows for easier extrusion and molding, reducing cycle times and minimizing defects. Homopolymers exhibit higher rigidity but can be more brittle, often necessitating careful temperature control during manufacturing to prevent cracking or warping.

Cost and Availability Considerations

Polystyrene homopolymers generally offer lower costs and wider availability due to simpler manufacturing processes and higher production volumes. Conversely, polystyrene copolymers, incorporating additional monomers like acrylonitrile or butadiene, tend to have elevated costs reflecting enhanced properties and more complex synthesis. Market demand and production scale significantly influence the price and accessibility differences between these two polystyrene types.

Environmental Impact and Recycling

Polystyrene copolymer typically includes additional monomers like acrylonitrile or butadiene, enhancing durability but complicating recycling processes compared to polystyrene homopolymer, which consists solely of styrene units. The presence of these comonomers in copolymers leads to reduced biodegradability and increased environmental persistence, resulting in greater challenges for waste management and recycling facilities. Polystyrene homopolymers are more straightforward to recycle due to their uniform chemical structure, enabling more efficient material recovery and lower environmental impact.

Polystyrene Copolymer vs Polystyrene Homopolymer Infographic

materialdif.com

materialdif.com