Expanded Polystyrene (EPS) and Extruded Polystyrene (XPS) differ primarily in their manufacturing process and performance characteristics. EPS consists of small beads fused together, resulting in a lightweight, cost-effective material with good insulating properties but lower moisture resistance. XPS is produced through an extrusion process, creating a denser, more durable foam with higher compressive strength and superior moisture resistance, making it ideal for applications requiring enhanced thermal insulation and durability.

Table of Comparison

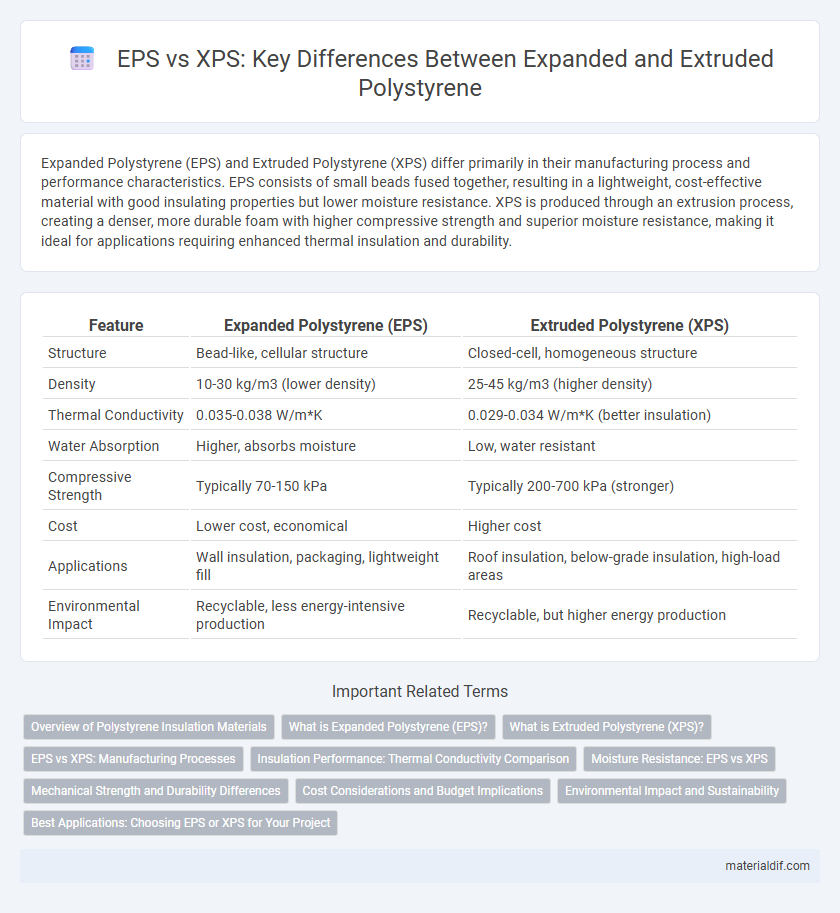

| Feature | Expanded Polystyrene (EPS) | Extruded Polystyrene (XPS) |

|---|---|---|

| Structure | Bead-like, cellular structure | Closed-cell, homogeneous structure |

| Density | 10-30 kg/m3 (lower density) | 25-45 kg/m3 (higher density) |

| Thermal Conductivity | 0.035-0.038 W/m*K | 0.029-0.034 W/m*K (better insulation) |

| Water Absorption | Higher, absorbs moisture | Low, water resistant |

| Compressive Strength | Typically 70-150 kPa | Typically 200-700 kPa (stronger) |

| Cost | Lower cost, economical | Higher cost |

| Applications | Wall insulation, packaging, lightweight fill | Roof insulation, below-grade insulation, high-load areas |

| Environmental Impact | Recyclable, less energy-intensive production | Recyclable, but higher energy production |

Overview of Polystyrene Insulation Materials

Expanded Polystyrene (EPS) and Extruded Polystyrene (XPS) are two primary types of polystyrene insulation materials widely used in construction for thermal insulation. EPS features a bead-like structure that provides good insulating properties at a lower cost and is highly vapor permeable, making it suitable for applications requiring moisture diffusion. XPS is produced through a continuous extrusion process, resulting in a closed-cell, rigid foam with superior compressive strength, moisture resistance, and higher R-value per inch compared to EPS, ideal for below-grade and high-load applications.

What is Expanded Polystyrene (EPS)?

Expanded Polystyrene (EPS) is a lightweight, rigid foam made from expanded polystyrene beads fused together through a steam molding process, characterized by its closed-cell structure that provides excellent thermal insulation and moisture resistance. Commonly used in packaging, insulation panels, and construction, EPS offers high impact absorption and cost-effectiveness compared to other insulation materials. Its open, bead-like structure distinguishes it from Extruded Polystyrene (XPS), which is denser and produced through an extrusion process resulting in a more uniform and closed-cell foam.

What is Extruded Polystyrene (XPS)?

Extruded Polystyrene (XPS) is a rigid foam insulation material created through a continuous extrusion process that produces closed-cell, moisture-resistant panels with a high compressive strength. XPS offers superior thermal insulation performance and durability compared to Expanded Polystyrene (EPS) due to its uniform cell structure and density ranging typically from 28 to 45 kg/m3. Commonly used in building applications such as foundation walls, roofs, and below-grade insulation, XPS provides long-lasting resistance to water absorption and mechanical stress.

EPS vs XPS: Manufacturing Processes

Expanded Polystyrene (EPS) is produced by expanding polystyrene beads through steam heating, allowing them to fuse into a lightweight, porous foam structure. Extruded Polystyrene (XPS) is manufactured by melting polystyrene crystals and extruding the material through a die, creating a closed-cell, dense foam with a consistent structure. The EPS process results in a bead-based, bead-fused foam, while the XPS process delivers a homogenous, strong foam with higher moisture resistance.

Insulation Performance: Thermal Conductivity Comparison

Expanded Polystyrene (EPS) typically exhibits a thermal conductivity of 0.035 to 0.040 W/m*K, while Extruded Polystyrene (XPS) offers lower thermal conductivity values ranging from 0.029 to 0.034 W/m*K, indicating superior insulation performance. The closed-cell structure of XPS enhances its moisture resistance and thermal efficiency compared to the more porous EPS. These differences make XPS a preferred choice for applications requiring higher thermal resistance and long-term durability in insulation.

Moisture Resistance: EPS vs XPS

Extruded Polystyrene (XPS) exhibits superior moisture resistance compared to Expanded Polystyrene (EPS), with XPS having a closed-cell structure that limits water absorption to less than 1%, making it ideal for below-grade applications. Expanded Polystyrene (EPS), consisting of a bead structure with higher porosity, typically absorbs more moisture, ranging from 2% to 4%, which can reduce its thermal performance over time. The enhanced moisture barrier of XPS contributes to greater durability and insulation stability in damp or wet environments.

Mechanical Strength and Durability Differences

Expanded Polystyrene (EPS) exhibits lower mechanical strength compared to Extruded Polystyrene (XPS) due to its bead-based structure, making XPS more resistant to compression and impact. XPS offers superior durability in moisture-rich environments owing to its closed-cell, uniform structure, which limits water absorption significantly. The enhanced density and structural integrity of XPS contribute to longer service life in insulation and protective packaging applications.

Cost Considerations and Budget Implications

Expanded Polystyrene (EPS) generally offers a lower initial cost compared to Extruded Polystyrene (XPS), making it a more budget-friendly option for large-scale insulation projects. XPS provides superior moisture resistance and higher R-values per inch, potentially reducing long-term energy expenses despite its higher upfront price. When considering cost-efficiency, project duration, climate conditions, and specific performance requirements play crucial roles in balancing the investment between EPS and XPS insulation materials.

Environmental Impact and Sustainability

Expanded Polystyrene (EPS) has a lower environmental impact compared to Extruded Polystyrene (XPS) due to its lower embodied energy and higher recyclability, making it more sustainable for insulation applications. EPS is primarily made from 98% air and is easier to recycle because it can be compacted efficiently, reducing landfill volume and resource consumption. XPS, although offering superior moisture resistance and insulation properties, relies on hydrofluorocarbon blowing agents that have a higher global warming potential, negatively affecting its sustainability profile.

Best Applications: Choosing EPS or XPS for Your Project

Expanded Polystyrene (EPS) is ideal for insulation in walls, floors, and roofs due to its excellent thermal performance, lightweight nature, and cost-effectiveness, making it suitable for residential and commercial construction. Extruded Polystyrene (XPS) offers superior moisture resistance and compressive strength, making it the preferred choice for below-grade applications like foundation walls, slabs, and roofing systems exposed to high humidity. Selecting EPS or XPS depends on project-specific needs such as moisture exposure, load-bearing requirements, and budget constraints to ensure optimal insulation efficiency and durability.

Expanded Polystyrene (EPS) vs Extruded Polystyrene (XPS) Infographic

materialdif.com

materialdif.com