Polystyrene blister packs offer superior clarity and rigidity compared to PVC blister packs, making them ideal for showcasing delicate products. Unlike PVC, polystyrene is environmentally friendlier due to its easier recyclability and lower chemical emissions during production. Polystyrene also provides better resistance to cracking and creasing, ensuring enhanced durability and product protection.

Table of Comparison

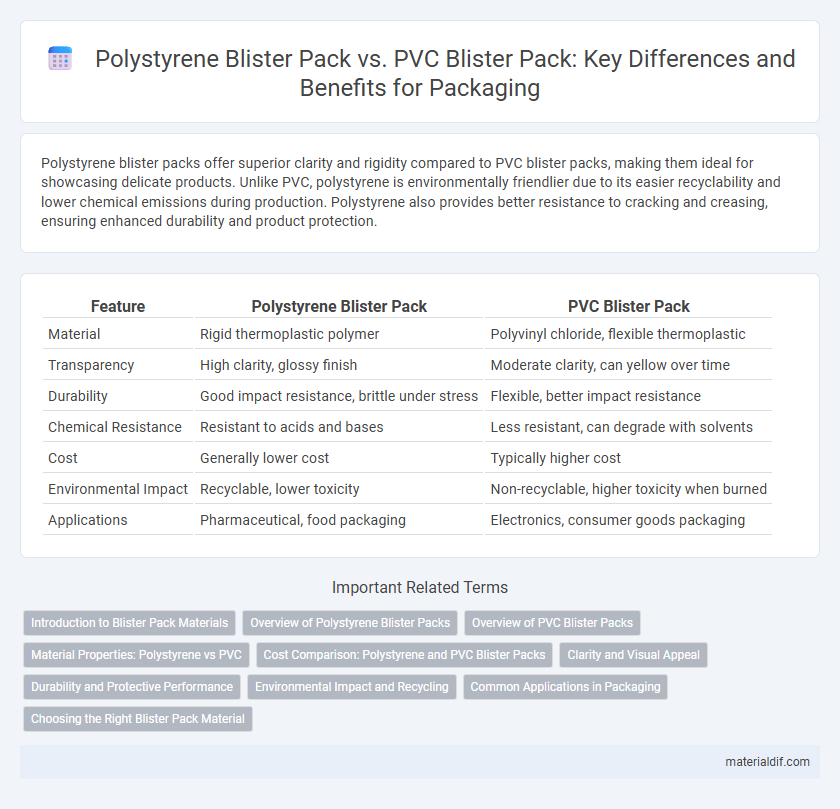

| Feature | Polystyrene Blister Pack | PVC Blister Pack |

|---|---|---|

| Material | Rigid thermoplastic polymer | Polyvinyl chloride, flexible thermoplastic |

| Transparency | High clarity, glossy finish | Moderate clarity, can yellow over time |

| Durability | Good impact resistance, brittle under stress | Flexible, better impact resistance |

| Chemical Resistance | Resistant to acids and bases | Less resistant, can degrade with solvents |

| Cost | Generally lower cost | Typically higher cost |

| Environmental Impact | Recyclable, lower toxicity | Non-recyclable, higher toxicity when burned |

| Applications | Pharmaceutical, food packaging | Electronics, consumer goods packaging |

Introduction to Blister Pack Materials

Polystyrene blister packs offer superior rigidity and clarity compared to PVC blister packs, making them ideal for high-visibility packaging. Polystyrene provides better resistance to moisture and environmental stress, enhancing product protection and shelf life. PVC blister packs, while flexible and cost-effective, often lack the durability and chemical stability of polystyrene in packaging applications.

Overview of Polystyrene Blister Packs

Polystyrene blister packs are lightweight and offer excellent clarity, allowing for high product visibility while providing good impact resistance. These packs are chemically stable and resistant to moisture, making them suitable for packaging pharmaceuticals, electronics, and consumer goods. Compared to PVC blister packs, polystyrene offers better recyclability and is less prone to yellowing over time, enhancing product presentation and sustainability.

Overview of PVC Blister Packs

PVC blister packs offer excellent clarity and rigidity, making them ideal for protecting and displaying consumer goods such as pharmaceuticals and electronics. Their chemical resistance and ability to be heat sealed provide a secure barrier against moisture and contamination. Compared to polystyrene blister packs, PVC packs typically provide greater durability and flexibility in design customization.

Material Properties: Polystyrene vs PVC

Polystyrene blister packs offer greater rigidity and clarity compared to PVC blister packs, making them ideal for showcasing products with a high-gloss finish. Polystyrene features excellent dimensional stability and resistance to moisture, while PVC provides superior flexibility and impact resistance but may yellow over time due to UV exposure. The thermal properties of polystyrene allow for easier thermoforming, whereas PVC's higher density contributes to sturdiness but at the cost of increased environmental concerns.

Cost Comparison: Polystyrene and PVC Blister Packs

Polystyrene blister packs typically offer a lower production cost compared to PVC blister packs due to the reduced raw material expenses and simplified manufacturing process. PVC blister packs incur higher costs because of their chemical additives that enhance flexibility and durability but increase overall price. Choosing polystyrene can result in significant cost savings while maintaining adequate protection for lightweight consumer goods.

Clarity and Visual Appeal

Polystyrene blister packs offer superior clarity compared to PVC blister packs, allowing products to be showcased with enhanced brightness and transparency. The high-gloss finish of polystyrene creates a sleek, visually appealing presentation that attracts consumer attention on retail shelves. PVC blister packs tend to have a slightly hazy appearance, making polystyrene the preferred choice for premium product packaging seeking maximum visual impact.

Durability and Protective Performance

Polystyrene blister packs offer superior durability and impact resistance compared to PVC blister packs, ensuring better protection for fragile products during transportation and storage. Their rigidity and higher tensile strength prevent deformation and provide a more secure enclosure, reducing the risk of damage. PVC blister packs, while flexible, tend to be less resistant to cracking and environmental stress, making polystyrene a preferred choice for long-lasting protective packaging.

Environmental Impact and Recycling

Polystyrene blister packs have a lower environmental impact compared to PVC blister packs due to their higher recyclability and reduced release of toxic chemicals during disposal. Polystyrene can be efficiently recycled into various products, decreasing landfill waste, whereas PVC blister packs often release harmful chlorine-based compounds when incinerated or improperly discarded. The preference for polystyrene in packaging supports sustainable waste management and aligns with increasing regulatory restrictions on PVC usage.

Common Applications in Packaging

Polystyrene blister packs are widely used for packaging consumer electronics, toys, and food items due to their rigidity and clarity, providing excellent product visibility and impact resistance. In contrast, PVC blister packs are favored for pharmaceutical packaging such as tablets and capsules because of their superior moisture barrier properties and ease of heat sealing. Both materials serve distinct roles in packaging, with polystyrene excelling in structural durability while PVC offers enhanced chemical resistance and flexibility.

Choosing the Right Blister Pack Material

Polystyrene blister packs offer excellent clarity, rigidity, and are cost-effective, making them ideal for lightweight consumer products requiring visual appeal. PVC blister packs provide superior flexibility, chemical resistance, and better barrier properties against moisture and oxygen, suitable for pharmaceuticals and medical devices. Selecting between polystyrene and PVC depends on product sensitivity, environmental exposure, and budget constraints, ensuring optimal protection and presentation.

Polystyrene Blister Pack vs PVC Blister Pack Infographic

materialdif.com

materialdif.com