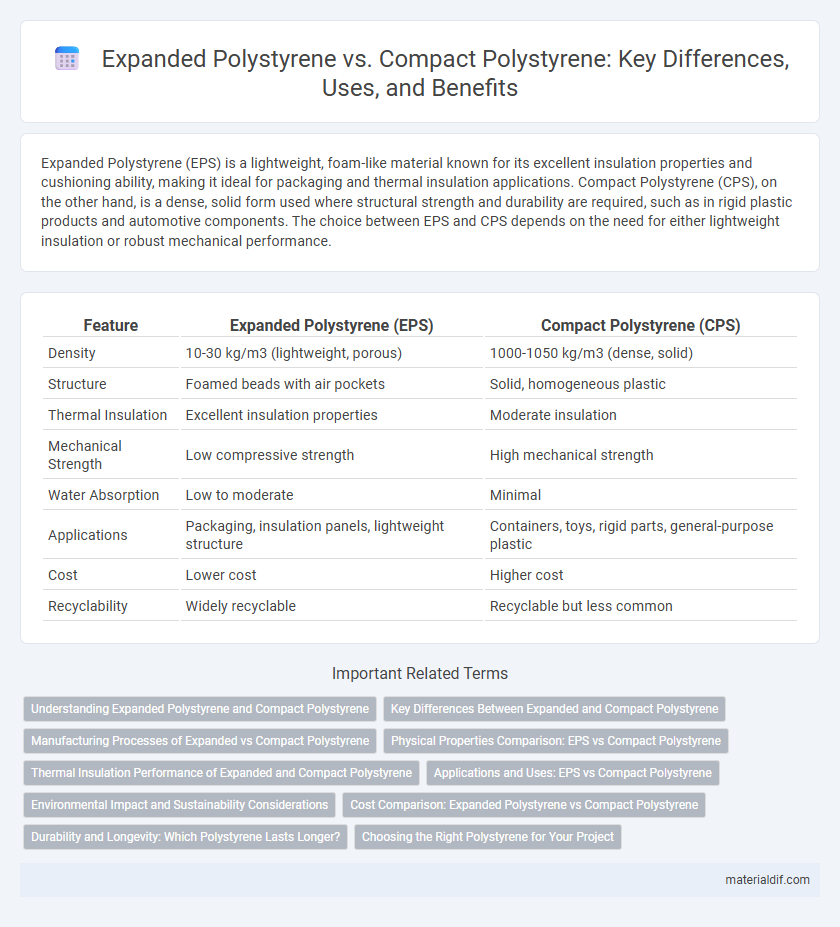

Expanded Polystyrene (EPS) is a lightweight, foam-like material known for its excellent insulation properties and cushioning ability, making it ideal for packaging and thermal insulation applications. Compact Polystyrene (CPS), on the other hand, is a dense, solid form used where structural strength and durability are required, such as in rigid plastic products and automotive components. The choice between EPS and CPS depends on the need for either lightweight insulation or robust mechanical performance.

Table of Comparison

| Feature | Expanded Polystyrene (EPS) | Compact Polystyrene (CPS) |

|---|---|---|

| Density | 10-30 kg/m3 (lightweight, porous) | 1000-1050 kg/m3 (dense, solid) |

| Structure | Foamed beads with air pockets | Solid, homogeneous plastic |

| Thermal Insulation | Excellent insulation properties | Moderate insulation |

| Mechanical Strength | Low compressive strength | High mechanical strength |

| Water Absorption | Low to moderate | Minimal |

| Applications | Packaging, insulation panels, lightweight structure | Containers, toys, rigid parts, general-purpose plastic |

| Cost | Lower cost | Higher cost |

| Recyclability | Widely recyclable | Recyclable but less common |

Understanding Expanded Polystyrene and Compact Polystyrene

Expanded polystyrene (EPS) consists of lightweight, rigid foam beads that are fused together, creating a material with excellent thermal insulation and shock absorption properties. Compact polystyrene, also known as solid polystyrene, is a dense, non-foamed plastic with high mechanical strength and clarity, commonly used for rigid packaging and consumer products. Understanding the differences between EPS and compact polystyrene is crucial for selecting the appropriate material based on insulation needs or structural performance requirements.

Key Differences Between Expanded and Compact Polystyrene

Expanded polystyrene (EPS) consists of small beads fused together, creating a lightweight, porous structure ideal for insulation and packaging, while compact polystyrene (CPS) is a denser, solid form with higher mechanical strength used in durable products and prototypes. EPS offers superior thermal insulation due to its trapped air pockets, whereas CPS provides better impact resistance and surface finish for detailed manufacturing. The choice between EPS and CPS depends on the application's requirements for weight, thermal properties, and structural integrity.

Manufacturing Processes of Expanded vs Compact Polystyrene

Expanded Polystyrene (EPS) manufacturing involves polymerizing styrene into beads, which are then expanded using steam to create a lightweight, porous foam structure. Compact Polystyrene (PS), also known as solid polystyrene, is produced by direct polymerization of styrene monomers into a dense, rigid plastic without expansion. The EPS process uses physical expansion and molding techniques, while compact PS relies on bulk polymerization and extrusion methods to achieve its solid form.

Physical Properties Comparison: EPS vs Compact Polystyrene

Expanded Polystyrene (EPS) exhibits lower density, typically ranging from 10 to 30 kg/m3, compared to Compact Polystyrene, which has a density between 1050 and 1100 kg/m3, resulting in significant differences in rigidity and compressive strength. EPS's cellular structure provides superior thermal insulation and shock absorption but reduced mechanical strength, whereas Compact Polystyrene offers better tensile strength and impact resistance due to its homogenous, solid composition. Moisture absorption rates are minimal in both types, but EPS can retain some water within its cells, influencing its performance in humid environments compared to the non-porous compact variant.

Thermal Insulation Performance of Expanded and Compact Polystyrene

Expanded Polystyrene (EPS) offers superior thermal insulation performance due to its cellular structure, which traps air and reduces heat transfer effectively. Compact Polystyrene, also known as solid or extruded polystyrene (XPS), has a denser composition that provides better moisture resistance but slightly lower insulation efficiency compared to EPS. Thermal conductivity values typically range from 0.030 to 0.040 W/m*K for EPS, whereas XPS values are around 0.035 to 0.045 W/m*K, highlighting EPS's advantage in energy-saving insulation applications.

Applications and Uses: EPS vs Compact Polystyrene

Expanded Polystyrene (EPS) is widely used for thermal insulation in construction, packaging for fragile items, and lightweight structural elements due to its excellent shock absorption and thermal resistance. Compact Polystyrene, also known as High Impact Polystyrene (HIPS), finds applications in consumer goods, food containers, and electronic housings where rigidity, durability, and ease of fabrication are critical. EPS excels in energy-efficient insulation and protective packaging, while compact polystyrene serves better in structural and impact-resistant product manufacturing.

Environmental Impact and Sustainability Considerations

Expanded polystyrene (EPS) features a lightweight, foam structure that enhances insulation but poses recycling challenges due to contamination and volume. Compact polystyrene (CPS), denser and less voluminous, offers better recyclability and reduced environmental footprint during disposal. Both materials require advanced recycling technologies to improve circularity and minimize landfill impact in sustainable building practices.

Cost Comparison: Expanded Polystyrene vs Compact Polystyrene

Expanded polystyrene (EPS) generally offers a lower cost per volume compared to compact polystyrene due to its lightweight, aerated structure, which reduces raw material usage. Compact polystyrene, being denser and more rigid, typically incurs higher production and material costs but provides superior durability and thermal insulation. Cost efficiency between EPS and compact polystyrene varies based on application requirements, including load-bearing capacity and insulation performance.

Durability and Longevity: Which Polystyrene Lasts Longer?

Expanded polystyrene (EPS) features a lightweight, foam-like structure that offers excellent thermal insulation but is more susceptible to physical damage and degradation over time compared to compact polystyrene. Compact polystyrene, also known as solid or extruded polystyrene (XPS), exhibits higher density and superior resistance to moisture, compression, and impact, resulting in greater durability and extended longevity in structural and insulation applications. For projects requiring long-lasting material performance, compact polystyrene typically outperforms expanded polystyrene, maintaining its integrity under prolonged environmental stress.

Choosing the Right Polystyrene for Your Project

Expanded polystyrene (EPS) offers superior insulation and lightweight properties, making it ideal for packaging, insulation, and craft projects requiring cushioning and thermal efficiency. Compact polystyrene (also known as high-impact polystyrene or HIPS) provides greater density, strength, and rigidity, suitable for structural components, prototypes, and durable consumer goods. Selecting the appropriate polystyrene depends on project requirements for strength, thermal insulation, and weight, ensuring optimal performance and cost-effectiveness.

Expanded Polystyrene vs Compact Polystyrene Infographic

materialdif.com

materialdif.com