Polystyrene foam offers excellent insulation properties and lightweight cushioning, making it ideal for packaging and thermal applications. Polystyrene sheets provide a rigid, durable surface suitable for signage, model making, and construction uses. Choosing between the two depends on the required density, flexibility, and structural strength for the specific PET project.

Table of Comparison

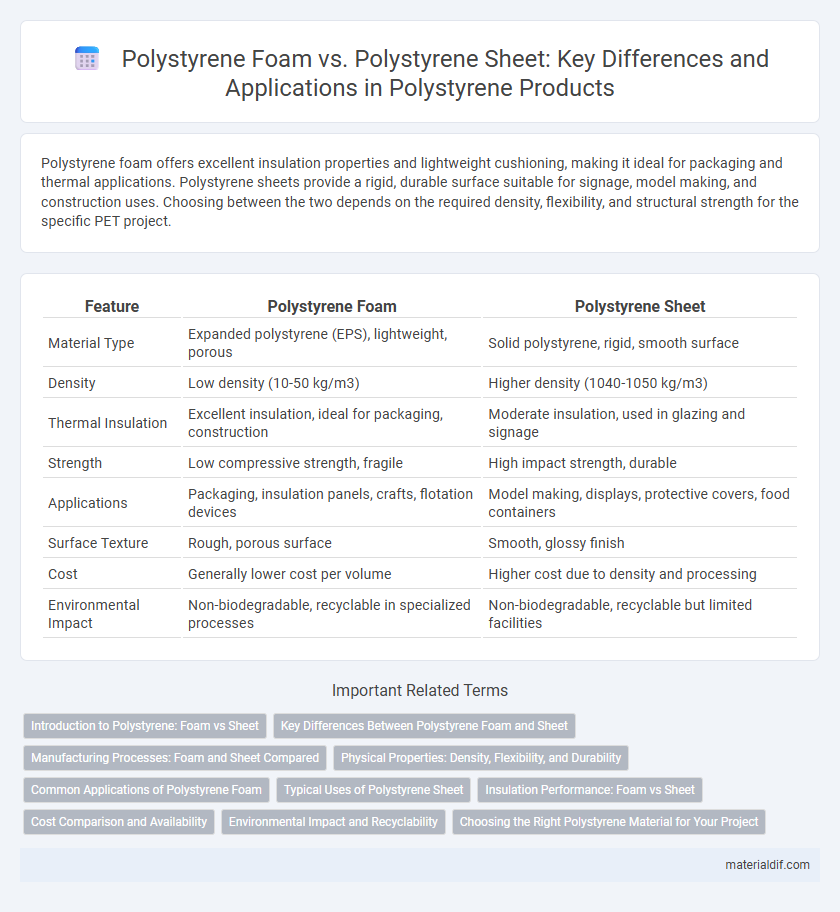

| Feature | Polystyrene Foam | Polystyrene Sheet |

|---|---|---|

| Material Type | Expanded polystyrene (EPS), lightweight, porous | Solid polystyrene, rigid, smooth surface |

| Density | Low density (10-50 kg/m3) | Higher density (1040-1050 kg/m3) |

| Thermal Insulation | Excellent insulation, ideal for packaging, construction | Moderate insulation, used in glazing and signage |

| Strength | Low compressive strength, fragile | High impact strength, durable |

| Applications | Packaging, insulation panels, crafts, flotation devices | Model making, displays, protective covers, food containers |

| Surface Texture | Rough, porous surface | Smooth, glossy finish |

| Cost | Generally lower cost per volume | Higher cost due to density and processing |

| Environmental Impact | Non-biodegradable, recyclable in specialized processes | Non-biodegradable, recyclable but limited facilities |

Introduction to Polystyrene: Foam vs Sheet

Polystyrene foam is a lightweight, expanded material commonly used for insulation, packaging, and cushioning due to its excellent thermal resistance and shock-absorbing properties. Polystyrene sheets, on the other hand, are solid, dense, and rigid, offering structural strength and versatility in applications such as signage, model making, and architectural detailing. Both forms originate from polystyrene resin but differ significantly in texture, density, and typical use cases.

Key Differences Between Polystyrene Foam and Sheet

Polystyrene foam consists of expanded or extruded beads creating a lightweight, insulating material ideal for packaging and thermal insulation, whereas polystyrene sheets are dense, solid panels used for structural applications and crafts. Foam exhibits greater cushioning properties and thermal resistance, while sheets offer higher rigidity and ease of cutting for precise fabrication. The distinct physical forms influence their suitability in industries ranging from construction to consumer goods.

Manufacturing Processes: Foam and Sheet Compared

Polystyrene foam is produced using a process called polymerization combined with a blowing agent that creates a cellular structure, resulting in lightweight, insulating material ideal for packaging and thermal insulation. In contrast, polystyrene sheets are manufactured through extrusion or casting methods, producing dense, flat, and rigid panels often used in signage, model making, or protective enclosures. The foam's manufacturing emphasizes expansion and trapping gas bubbles, while sheet production prioritizes uniform thickness and smooth surfaces through controlled melting and cooling.

Physical Properties: Density, Flexibility, and Durability

Polystyrene foam exhibits low density, making it lightweight and ideal for insulation and packaging, while polystyrene sheets possess higher density, contributing to superior rigidity and structural support. Foam offers greater flexibility due to its cellular structure, enabling cushioning and impact absorption, contrasted with the stiffness of sheets which resist deformation under stress. Durability in polystyrene sheets surpasses that of foam, providing enhanced resistance to physical damage and environmental factors such as moisture and UV exposure.

Common Applications of Polystyrene Foam

Polystyrene foam is widely used in insulation for buildings, packaging materials, and disposable food containers due to its lightweight and thermal resistance properties. Its ability to absorb shock makes it ideal for protecting fragile items during shipping and in craft applications, including model making. Unlike polystyrene sheets, which are preferred for rigid displays and signage, polystyrene foam is the go-to material for cushioning and thermal insulation.

Typical Uses of Polystyrene Sheet

Polystyrene sheets are commonly used in architectural models, signage, and packaging due to their rigid structure and ease of cutting. Their smooth surface makes them ideal for printing and painting applications, which is less practical with polystyrene foam. Unlike foam, polystyrene sheets provide excellent dimensional stability, making them suitable for precise fabrication and prototyping tasks.

Insulation Performance: Foam vs Sheet

Polystyrene foam offers superior insulation performance compared to polystyrene sheets due to its closed-cell structure, which effectively reduces heat transfer and provides higher R-values per inch. While polystyrene sheets are denser and more rigid, their insulation capacity is lower, making them less efficient for thermal barriers. Foam types such as expanded polystyrene (EPS) and extruded polystyrene (XPS) are commonly preferred in construction for enhanced energy efficiency and moisture resistance.

Cost Comparison and Availability

Polystyrene foam is generally more cost-effective and widely available for insulation and packaging applications due to its lightweight structure and ease of manufacturing. Polystyrene sheets, while offering higher durability and rigidity, typically come at a higher price point and are less common in bulk quantities. Market availability favors foam products, making them the preferred choice for large-scale commercial uses requiring cost efficiency.

Environmental Impact and Recyclability

Polystyrene foam, commonly used in packaging and insulation, poses significant environmental challenges due to its low density, which leads to widespread litter and slow degradation in natural environments. In contrast, polystyrene sheets, often employed in construction and crafts, tend to be more easily recyclable because of their compact form and higher material volume. Both materials require specialized recycling processes, but polystyrene sheets generally offer a more sustainable option by reducing waste volume and improving recycling efficiency.

Choosing the Right Polystyrene Material for Your Project

Polystyrene foam offers excellent insulation and cushioning properties, ideal for packaging, insulation, and craft projects requiring lightweight material with thermal resistance. Polystyrene sheets provide rigidity, durability, and a smooth surface suitable for model making, signage, and structural components where strength and precision are essential. Selecting the right polystyrene material depends on project needs such as impact resistance, thermal insulation, and ease of shaping or cutting.

Polystyrene Foam vs Polystyrene Sheet Infographic

materialdif.com

materialdif.com