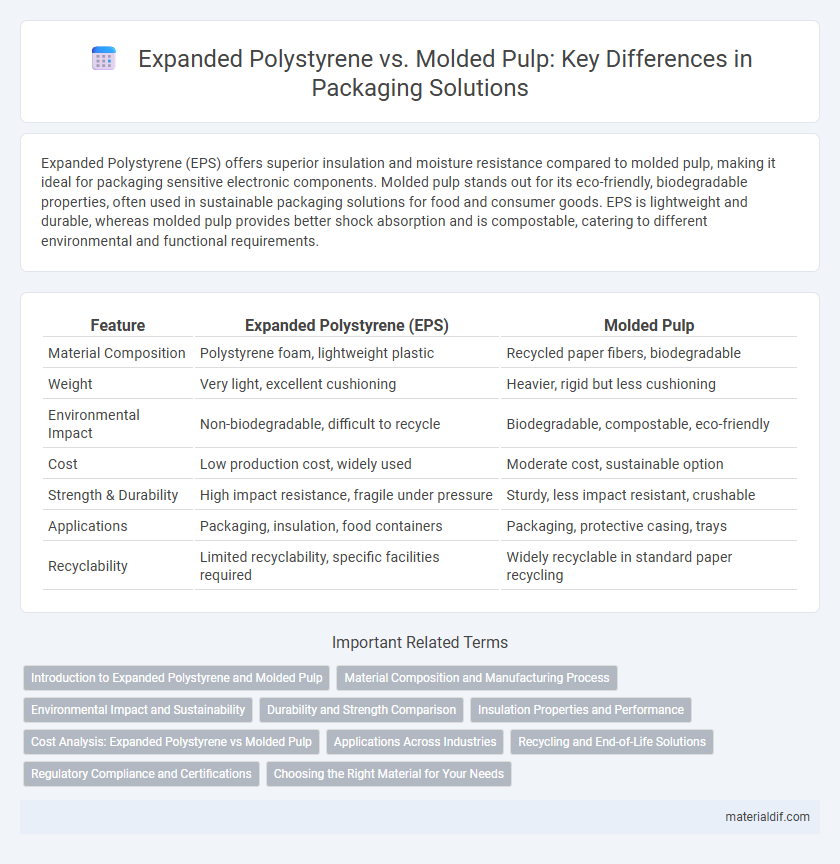

Expanded Polystyrene (EPS) offers superior insulation and moisture resistance compared to molded pulp, making it ideal for packaging sensitive electronic components. Molded pulp stands out for its eco-friendly, biodegradable properties, often used in sustainable packaging solutions for food and consumer goods. EPS is lightweight and durable, whereas molded pulp provides better shock absorption and is compostable, catering to different environmental and functional requirements.

Table of Comparison

| Feature | Expanded Polystyrene (EPS) | Molded Pulp |

|---|---|---|

| Material Composition | Polystyrene foam, lightweight plastic | Recycled paper fibers, biodegradable |

| Weight | Very light, excellent cushioning | Heavier, rigid but less cushioning |

| Environmental Impact | Non-biodegradable, difficult to recycle | Biodegradable, compostable, eco-friendly |

| Cost | Low production cost, widely used | Moderate cost, sustainable option |

| Strength & Durability | High impact resistance, fragile under pressure | Sturdy, less impact resistant, crushable |

| Applications | Packaging, insulation, food containers | Packaging, protective casing, trays |

| Recyclability | Limited recyclability, specific facilities required | Widely recyclable in standard paper recycling |

Introduction to Expanded Polystyrene and Molded Pulp

Expanded Polystyrene (EPS) is a lightweight, rigid foam plastic material composed of closed-cell beads, widely used for insulation and packaging due to its excellent thermal properties and shock absorption. Molded Pulp, made from recycled paper fibers, offers a sustainable alternative with biodegradability and compostability, ideal for protective packaging and environmentally friendly applications. Both materials serve distinct market needs, with EPS excelling in lightweight cushioning and Molded Pulp emphasizing eco-conscious material usage.

Material Composition and Manufacturing Process

Expanded Polystyrene (EPS) is a lightweight foam composed primarily of polystyrene beads that are expanded with steam and fused into rigid, closed-cell structures through a mold-based heating process. Molded pulp, on the other hand, is made from recycled paper fibers and water, which are formed into a pulp slurry and shaped using a molding process that involves pressing and drying to create biodegradable packaging products. The EPS manufacturing process relies on polymer bead expansion and thermal fusion, whereas molded pulp emphasizes sustainability through repurposed materials and water-based forming techniques.

Environmental Impact and Sustainability

Expanded Polystyrene (EPS) is a petroleum-based plastic known for its lightweight insulating properties but poses significant environmental challenges due to its non-biodegradability and difficulty in recycling. Molded pulp, derived from recycled paper fibers, offers a sustainable alternative by being biodegradable, compostable, and easily recyclable, reducing landfill waste and environmental pollution. While EPS has higher energy consumption during production, molded pulp supports circular economy principles, making it a more eco-friendly choice for packaging and protective applications.

Durability and Strength Comparison

Expanded Polystyrene (EPS) offers superior durability and strength compared to molded pulp, making it ideal for protective packaging and insulation applications. EPS exhibits excellent resistance to impact, moisture, and compression, while molded pulp is more prone to deformation and damage under stress. The rigid structure of EPS provides enhanced cushioning and long-term performance in demanding environments.

Insulation Properties and Performance

Expanded Polystyrene (EPS) offers superior thermal insulation due to its closed-cell structure, which effectively reduces heat transfer and maintains temperature stability. Molded Pulp, composed of recycled fibers, has lower insulation performance because its porous and fibrous composition allows more air permeability and heat conduction. EPS excels in energy efficiency for building insulation and packaging applications, while molded pulp is favored for sustainable, biodegradable options despite its modest insulating capabilities.

Cost Analysis: Expanded Polystyrene vs Molded Pulp

Expanded polystyrene (EPS) typically offers lower material and production costs compared to molded pulp, making it a more economical choice for mass-produced packaging and insulation applications. Molded pulp, derived from recycled paper fibers, often incurs higher processing expenses due to drying and molding techniques, which can raise overall costs despite its environmental benefits. Cost analysis reveals that EPS provides superior affordability in large-scale manufacturing, while molded pulp may incur premium pricing linked to sustainable packaging demand.

Applications Across Industries

Expanded polystyrene (EPS) is widely used in construction for insulation, packaging for protecting fragile goods, and food service for disposable containers due to its lightweight and cushioning properties. Molded pulp excels in sustainable packaging solutions, especially for electronics, consumer goods, and agricultural products, offering biodegradability and shock absorption. Industries prioritize EPS for thermal insulation and durability, while molded pulp is favored for eco-friendly, compostable packaging alternatives.

Recycling and End-of-Life Solutions

Expanded Polystyrene (EPS) offers high recyclability through established mechanical recycling processes, allowing it to be transformed into new insulation materials, packaging, and consumer products, though contamination can limit recycling efficiency. Molded pulp, made from recycled paper fibers, is fully biodegradable and compostable, providing a sustainable end-of-life solution that reduces landfill impact but lacks the economic recycling value found in EPS. While EPS recycling infrastructure is more developed in industrial regions, molded pulp's compostability aligns it with circular economy principles by returning organic material safely to the environment.

Regulatory Compliance and Certifications

Expanded Polystyrene (EPS) typically complies with fire safety standards such as ASTM E84 and meets FDA regulations for food contact applications, while molded pulp primarily adheres to environmental certifications like FSC and compostability standards. EPS is often certified for thermal insulation efficiency under Energy Star and LEED, whereas molded pulp is favored for its biodegradability and certifications like OK compost and BPI. Regulatory compliance for EPS centers on chemical safety and performance metrics, contrasting with molded pulp's emphasis on sustainability and waste reduction certifications.

Choosing the Right Material for Your Needs

Expanded polystyrene (EPS) offers superior insulation, lightweight durability, and moisture resistance, making it ideal for packaging fragile items and thermal insulation applications. Molded pulp, made from recycled paper fibers, excels in environmental sustainability and biodegradability, preferred for eco-friendly packaging solutions. Select EPS when strength and moisture protection are priorities, while molded pulp suits companies targeting biodegradable and recyclable materials for their packaging needs.

Expanded Polystyrene vs Molded Pulp Infographic

materialdif.com

materialdif.com