Polystyrene clamshell packaging offers a hinged design that provides secure enclosure and easy access, making it ideal for larger or irregularly shaped products. Polystyrene blister packaging, in contrast, features a pre-formed cavity that holds items firmly in place, enhancing product visibility and tamper resistance. Both options deliver lightweight, durable protection while catering to different display and consumer interaction needs in retail environments.

Table of Comparison

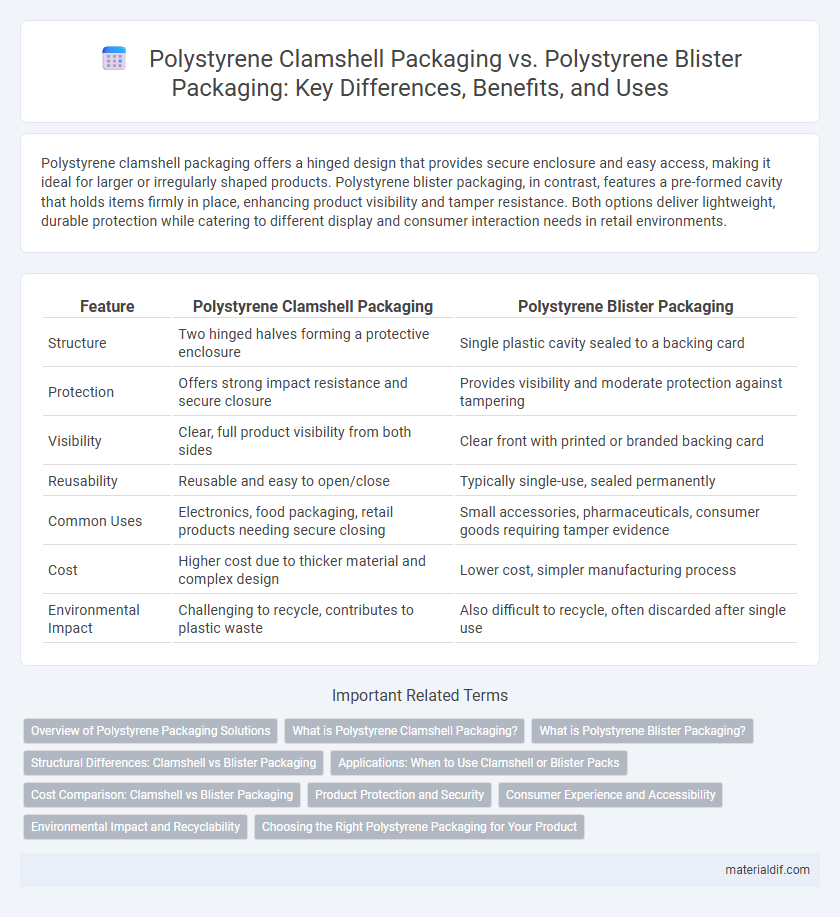

| Feature | Polystyrene Clamshell Packaging | Polystyrene Blister Packaging |

|---|---|---|

| Structure | Two hinged halves forming a protective enclosure | Single plastic cavity sealed to a backing card |

| Protection | Offers strong impact resistance and secure closure | Provides visibility and moderate protection against tampering |

| Visibility | Clear, full product visibility from both sides | Clear front with printed or branded backing card |

| Reusability | Reusable and easy to open/close | Typically single-use, sealed permanently |

| Common Uses | Electronics, food packaging, retail products needing secure closing | Small accessories, pharmaceuticals, consumer goods requiring tamper evidence |

| Cost | Higher cost due to thicker material and complex design | Lower cost, simpler manufacturing process |

| Environmental Impact | Challenging to recycle, contributes to plastic waste | Also difficult to recycle, often discarded after single use |

Overview of Polystyrene Packaging Solutions

Polystyrene clamshell packaging offers rigid, hinged containers ideal for protecting fragile goods and providing tamper-evident seals, often used in food and consumer electronics industries. Polystyrene blister packaging features a pre-formed cavity sealed onto a backing card, enhancing product visibility and reducing tampering risks, commonly employed for pharmaceuticals and small hardware items. Both solutions capitalize on polystyrene's lightweight, durable, and cost-effective properties, catering to diverse packaging needs with varying levels of protection and presentation.

What is Polystyrene Clamshell Packaging?

Polystyrene clamshell packaging consists of two hinged halves made from durable, clear polystyrene plastic, designed to securely encase and display products while providing tamper resistance and impact protection. Widely used in retail for items like electronics, food, and cosmetics, it offers excellent visibility and product security. The rigid structure of polystyrene clamshells allows for efficient stacking and transportation, making it a popular choice for both manufacturers and retailers.

What is Polystyrene Blister Packaging?

Polystyrene blister packaging is a type of rigid, transparent container made from polystyrene resin, designed to securely hold and display small consumer goods, pharmaceuticals, or electronics. This packaging features thermoformed cavities or pockets molded to the shape of the product, offering protection against damage, contamination, and tampering while allowing clear product visibility. Compared to clamshell packaging, polystyrene blisters provide a lightweight, cost-effective solution with a compact design ideal for hanging displays and easy inventory management.

Structural Differences: Clamshell vs Blister Packaging

Polystyrene clamshell packaging features a hinged, two-piece design that encloses products securely with a robust structure ideal for bulky or fragile items. Polystyrene blister packaging consists of a pre-formed plastic cavity sealed onto a backing card, offering a clear, molded shape that highlights smaller products while providing tamper resistance. The structural difference impacts product visibility, protection level, and ease of use, with clamshells providing bulkier protection and blisters emphasizing product display and compact security.

Applications: When to Use Clamshell or Blister Packs

Polystyrene clamshell packaging is ideal for products requiring secure, reusable protection and easy access, such as electronics, toys, and food items like bakery goods. Polystyrene blister packaging suits smaller, lightweight products needing tamper-evident seals and visibility, including pharmaceuticals, cosmetics, and hardware components. Choosing between clamshell or blister packs depends on product size, security needs, and the importance of visibility for consumer appeal.

Cost Comparison: Clamshell vs Blister Packaging

Polystyrene clamshell packaging generally incurs higher production costs due to its complex molding process and increased material usage compared to polystyrene blister packaging, which benefits from simpler thermoforming techniques and lower material consumption. The cost efficiency of blister packaging makes it a preferred choice for high-volume, low-cost products, while clamshell packaging justifies its expense by offering superior product protection and aesthetic appeal. Manufacturers must weigh the upfront material and manufacturing expenses against the packaging's functional benefits and market positioning.

Product Protection and Security

Polystyrene clamshell packaging offers superior product protection through its rigid, impact-resistant structure that securely encloses items, minimizing damage during transit. Polystyrene blister packaging provides enhanced product visibility with a clear, form-fitting design but may offer less impact resistance compared to clamshells. Both packaging types ensure tamper evidence, yet clamshells typically deliver higher security due to their robust sealing mechanisms.

Consumer Experience and Accessibility

Polystyrene clamshell packaging offers superior product visibility and easy hinge-opening, enhancing consumer convenience and tactile interaction. Polystyrene blister packaging provides tamper-evident security but can be challenging to open, often requiring scissors, which may reduce accessibility for individuals with limited dexterity. The choice between clamshell and blister packaging directly impacts consumer satisfaction by balancing ease of use and product protection.

Environmental Impact and Recyclability

Polystyrene clamshell packaging offers a rigid, protective enclosure frequently used for food and consumer products, but its bulky nature results in challenges for efficient recycling and contributes to significant landfill accumulation. Polystyrene blister packaging, characterized by a thin, molded plastic shell sealed to a backing card, generally uses less material and can be easier to recycle when separated properly, though mixed materials often complicate processing. Both types pose environmental concerns due to polystyrene's persistence in ecosystems and limited biodegradability, emphasizing the need for improved recycling infrastructure and alternative sustainable materials.

Choosing the Right Polystyrene Packaging for Your Product

Polystyrene clamshell packaging offers superior protection and resealability, making it ideal for bulky or fragile products that require multiple uses or display visibility. Polystyrene blister packaging provides a lightweight, tamper-evident solution best suited for small consumer goods needing high retail visibility and secure containment. Selecting the right polystyrene packaging depends on product size, fragility, display requirements, and user convenience to maximize durability and consumer appeal.

Polystyrene Clamshell Packaging vs Polystyrene Blister Packaging Infographic

materialdif.com

materialdif.com