Polystyrene insulation offers superior moisture resistance and higher R-values compared to mineral wool, making it ideal for environments prone to dampness. Mineral wool insulation excels in fire resistance and soundproofing, providing enhanced safety and acoustic benefits. Choosing between polystyrene and mineral wool depends on specific project needs such as thermal performance, fire safety, and environmental exposure.

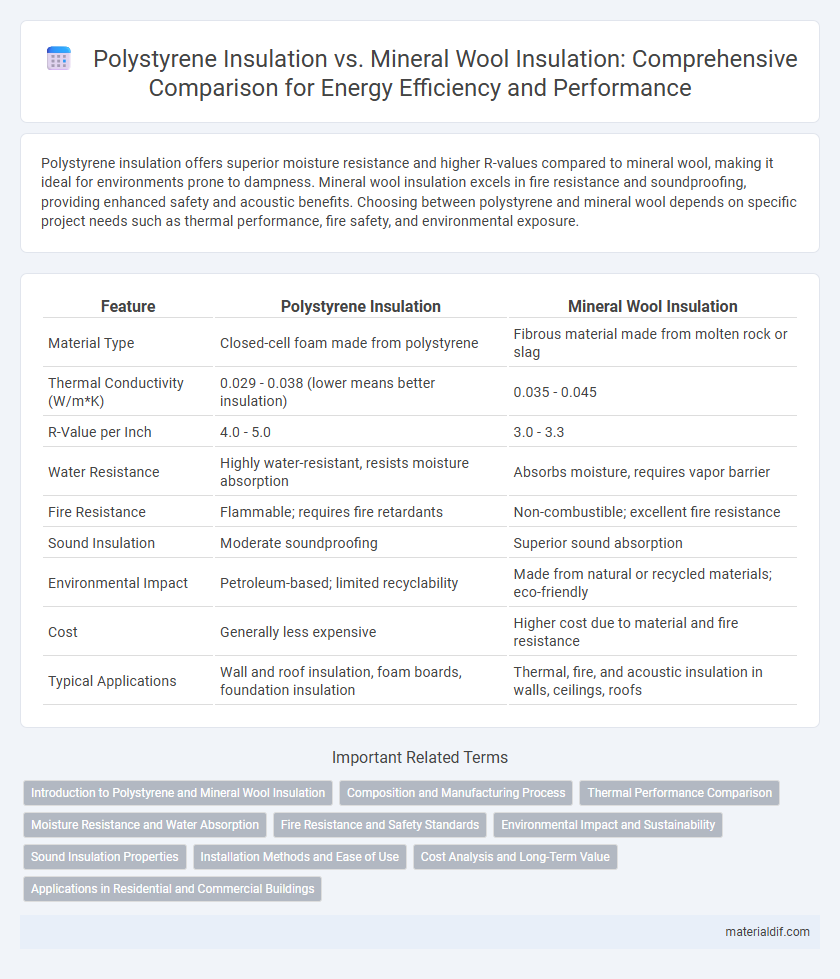

Table of Comparison

| Feature | Polystyrene Insulation | Mineral Wool Insulation |

|---|---|---|

| Material Type | Closed-cell foam made from polystyrene | Fibrous material made from molten rock or slag |

| Thermal Conductivity (W/m*K) | 0.029 - 0.038 (lower means better insulation) | 0.035 - 0.045 |

| R-Value per Inch | 4.0 - 5.0 | 3.0 - 3.3 |

| Water Resistance | Highly water-resistant, resists moisture absorption | Absorbs moisture, requires vapor barrier |

| Fire Resistance | Flammable; requires fire retardants | Non-combustible; excellent fire resistance |

| Sound Insulation | Moderate soundproofing | Superior sound absorption |

| Environmental Impact | Petroleum-based; limited recyclability | Made from natural or recycled materials; eco-friendly |

| Cost | Generally less expensive | Higher cost due to material and fire resistance |

| Typical Applications | Wall and roof insulation, foam boards, foundation insulation | Thermal, fire, and acoustic insulation in walls, ceilings, roofs |

Introduction to Polystyrene and Mineral Wool Insulation

Polystyrene insulation, a rigid foam material, offers high thermal resistance and moisture resistance, making it ideal for energy-efficient building envelopes. Mineral wool insulation, composed of natural rock or slag fibers, provides excellent fire resistance and soundproofing properties. Both materials serve distinct roles in insulation, with polystyrene excelling in moisture control and mineral wool favored for durability and fire safety.

Composition and Manufacturing Process

Polystyrene insulation is primarily composed of expanded or extruded polystyrene beads derived from styrene monomers through polymerization, resulting in a rigid, closed-cell foam with excellent moisture resistance. Mineral wool insulation is manufactured by melting natural rocks such as basalt or diabase at high temperatures, then spinning the molten material into fibrous strands that create a dense, non-combustible structure with superior fire resistance. The manufacturing process for polystyrene typically involves molding or extrusion techniques, whereas mineral wool requires high-temperature melting and fiber formation, influencing their respective thermal and acoustic properties.

Thermal Performance Comparison

Polystyrene insulation, particularly expanded (EPS) and extruded (XPS) types, offers a high R-value ranging from 3.6 to 5 per inch, providing superior thermal resistance compared to mineral wool insulation, which typically has an R-value of about 3.1 to 3.3 per inch. The closed-cell structure of XPS contributes to its lower thermal conductivity and better moisture resistance, enhancing its overall thermal performance in damp environments. Mineral wool, while slightly less efficient thermally, excels in fire resistance and sound absorption, making it a balanced choice based on specific building requirements.

Moisture Resistance and Water Absorption

Polystyrene insulation exhibits superior moisture resistance compared to mineral wool insulation, with water absorption rates typically below 1%, making it highly effective in preventing water damage and maintaining thermal performance. Mineral wool, although fire-resistant and sound-absorbing, tends to absorb more water due to its fibrous structure, which can lead to diminished insulation efficiency and potential mold growth. Choosing polystyrene insulation ensures better durability and sustained insulating properties in moist or wet environments.

Fire Resistance and Safety Standards

Polystyrene insulation offers moderate fire resistance but typically requires flame retardant additives to meet safety standards, whereas mineral wool insulation inherently provides superior fire resistance due to its non-combustible, inorganic composition. Mineral wool can withstand temperatures above 1,000degC without igniting, making it ideal for applications requiring stringent fire safety compliance such as building codes and insurance regulations. Polystyrene's lower melting point and combustible nature limit its use in fire-critical zones despite its thermal insulation efficiency.

Environmental Impact and Sustainability

Polystyrene insulation generates more greenhouse gas emissions during production compared to mineral wool, which is made from natural or recycled materials with lower embodied energy. Mineral wool is highly recyclable and non-toxic, while polystyrene can persist in the environment for centuries and poses challenges in waste management. Choosing mineral wool insulation supports sustainability goals by reducing landfill waste and minimizing harmful environmental effects throughout its lifecycle.

Sound Insulation Properties

Polystyrene insulation offers moderate soundproofing qualities with its closed-cell structure, effectively reducing airborne noise but less efficient at blocking low-frequency sounds compared to mineral wool. Mineral wool insulation excels in sound absorption due to its dense, fibrous composition, providing superior acoustic performance by dampening a wider range of sound frequencies, including impact noise and vibrations. For optimal sound insulation in residential or commercial buildings, mineral wool remains the preferred choice for comprehensive noise control.

Installation Methods and Ease of Use

Polystyrene insulation is lightweight, rigid, and typically comes in foam board panels that are easily cut and fitted into place using adhesive or mechanical fasteners, enabling quick and straightforward installation in walls, roofs, and foundations. Mineral wool insulation, available in batts or loose-fill forms, requires careful handling to avoid fibers respiration and often needs precise cutting and fitting, which can be more labor-intensive and time-consuming. Polystyrene's moisture resistance and ease of handling make it generally more user-friendly, whereas mineral wool provides superior fire resistance but demands protective gear and more meticulous installation practices.

Cost Analysis and Long-Term Value

Polystyrene insulation typically offers a lower initial cost compared to mineral wool, making it a budget-friendly option for many construction projects. Despite the higher upfront cost, mineral wool provides superior fire resistance, soundproofing, and durability, resulting in better long-term value and reduced maintenance expenses. Lifecycle cost analysis often favors mineral wool due to its resilience and energy efficiency, which can lead to significant savings over time.

Applications in Residential and Commercial Buildings

Polystyrene insulation, known for its high thermal resistance and moisture resistance, is widely used in both residential and commercial building applications, especially in walls, roofs, and foundation insulation where moisture control is critical. Mineral wool insulation, favored for its fire resistance and soundproofing properties, is commonly applied in commercial buildings for acoustic barriers and in residential properties requiring enhanced fire safety. Both materials serve crucial roles in energy efficiency, but polystyrene is preferred in damp areas while mineral wool excels in fire-rated assemblies and noise reduction.

Polystyrene Insulation vs Mineral Wool Insulation Infographic

materialdif.com

materialdif.com