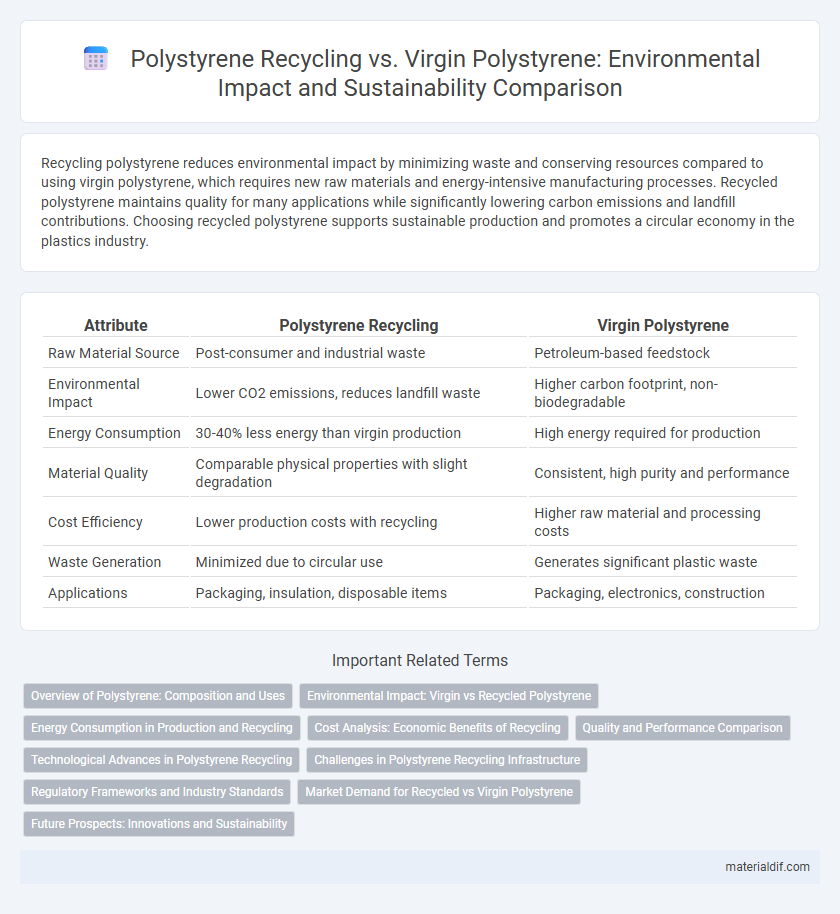

Recycling polystyrene reduces environmental impact by minimizing waste and conserving resources compared to using virgin polystyrene, which requires new raw materials and energy-intensive manufacturing processes. Recycled polystyrene maintains quality for many applications while significantly lowering carbon emissions and landfill contributions. Choosing recycled polystyrene supports sustainable production and promotes a circular economy in the plastics industry.

Table of Comparison

| Attribute | Polystyrene Recycling | Virgin Polystyrene |

|---|---|---|

| Raw Material Source | Post-consumer and industrial waste | Petroleum-based feedstock |

| Environmental Impact | Lower CO2 emissions, reduces landfill waste | Higher carbon footprint, non-biodegradable |

| Energy Consumption | 30-40% less energy than virgin production | High energy required for production |

| Material Quality | Comparable physical properties with slight degradation | Consistent, high purity and performance |

| Cost Efficiency | Lower production costs with recycling | Higher raw material and processing costs |

| Waste Generation | Minimized due to circular use | Generates significant plastic waste |

| Applications | Packaging, insulation, disposable items | Packaging, electronics, construction |

Overview of Polystyrene: Composition and Uses

Polystyrene consists primarily of the polymer styrene, a derivative of benzene, known for its lightweight and rigid properties, making it widely used in packaging, insulation, and disposable cutlery. Virgin polystyrene offers consistent quality and clarity, critical for food-grade applications and optical products, while recycled polystyrene is mainly utilized in construction materials, automotive parts, and lower-grade packaging. The recycling process aims to reduce environmental impact by repurposing polystyrene waste, although challenges include contamination, degradation of mechanical properties, and typically higher production costs compared to virgin material.

Environmental Impact: Virgin vs Recycled Polystyrene

Recycled polystyrene significantly reduces environmental impact by lowering energy consumption and greenhouse gas emissions compared to virgin polystyrene, which requires extraction and polymerization of fossil fuels. Recycling polystyrene also decreases landfill volume and prevents microplastic contamination in ecosystems. However, challenges in recycling purity and performance limits still make virgin polystyrene prevalent in high-spec applications.

Energy Consumption in Production and Recycling

Recycling polystyrene consumes significantly less energy compared to producing virgin polystyrene, with recycled polystyrene requiring up to 40% less energy due to bypassing the extraction and polymerization processes. Virgin polystyrene production involves high energy inputs from raw material extraction, refining, and polymerization, amounting to approximately 73 MJ per kilogram. The energy savings in polystyrene recycling contribute to reduced greenhouse gas emissions and lower overall environmental impact, making recycling a more sustainable option.

Cost Analysis: Economic Benefits of Recycling

Recycling polystyrene significantly reduces production costs compared to virgin polystyrene by lowering raw material expenses and decreasing energy consumption by up to 60%. The economic benefits include minimized landfill fees and reduced carbon footprint, translating to substantial savings for manufacturers and municipalities. Market demand for recycled polystyrene pellets supports competitive pricing, driving a cost-effective circular economy within the plastic industry.

Quality and Performance Comparison

Recycled polystyrene typically exhibits slightly reduced mechanical strength and clarity compared to virgin polystyrene, affecting its suitability for high-performance applications. Virgin polystyrene maintains superior structural integrity and consistent transparency, making it ideal for food packaging and medical components. Advances in recycling technology have improved recycled polystyrene quality, but virgin material still outperforms in durability and aesthetic properties.

Technological Advances in Polystyrene Recycling

Technological advances in polystyrene recycling have significantly improved the efficiency and quality of recycled products compared to virgin polystyrene. Innovations such as enhanced dissolution and depolymerization processes enable recovery of high-purity polystyrene suitable for packaging and insulation applications. These advancements reduce environmental impact by minimizing landfill waste and decreasing reliance on fossil fuel-derived raw materials.

Challenges in Polystyrene Recycling Infrastructure

Polystyrene recycling faces significant challenges due to its low density and high contaminant sensitivity, making collection and processing economically inefficient compared to virgin polystyrene production. Recycling infrastructure struggles with the segregation of polystyrene waste, as it is often mixed with food residues and other plastics, complicating sorting and reducing material quality. Limited access to advanced recycling technologies and the lack of standardized recycling protocols further hinder scaling sustainable polystyrene recycling efforts.

Regulatory Frameworks and Industry Standards

Polystyrene recycling is increasingly governed by stringent regulatory frameworks such as the European Union's Waste Framework Directive and the U.S. EPA's Resource Conservation and Recovery Act, which mandate reductions in landfill waste and promote material recovery. Industry standards like ASTM D1238 and ISO 1872 ensure recycled polystyrene meets performance and safety criteria comparable to virgin polystyrene, encouraging its adoption in manufacturing. Compliance with these regulations and standards drives the expansion of recycled polystyrene use while supporting sustainable circular economy goals in plastics management.

Market Demand for Recycled vs Virgin Polystyrene

Market demand for recycled polystyrene is steadily increasing due to growing environmental regulations and consumer preference for sustainable products, yet virgin polystyrene still dominates the market because of its consistent quality and lower production costs. Recycled polystyrene often faces limitations in application scope and material performance, restricting its use primarily to non-food packaging and insulation products. Innovations in recycling technologies are gradually improving the quality of recycled polystyrene, potentially narrowing the gap with virgin material in high-demand sectors such as packaging and construction.

Future Prospects: Innovations and Sustainability

Advancements in chemical recycling technologies for polystyrene are enhancing the feasibility of converting post-consumer waste into high-quality recycled material, reducing dependence on virgin polystyrene derived from petroleum. Emerging bio-based alternatives and enhanced mechanical recycling methods aim to improve sustainability by lowering carbon footprints and promoting circular economy models. Industrial collaborations and government incentives are accelerating research on scalable solutions, positioning recycled polystyrene as a viable, eco-friendly substitute for virgin counterparts in packaging and insulation markets.

Polystyrene recycling vs Virgin polystyrene Infographic

materialdif.com

materialdif.com