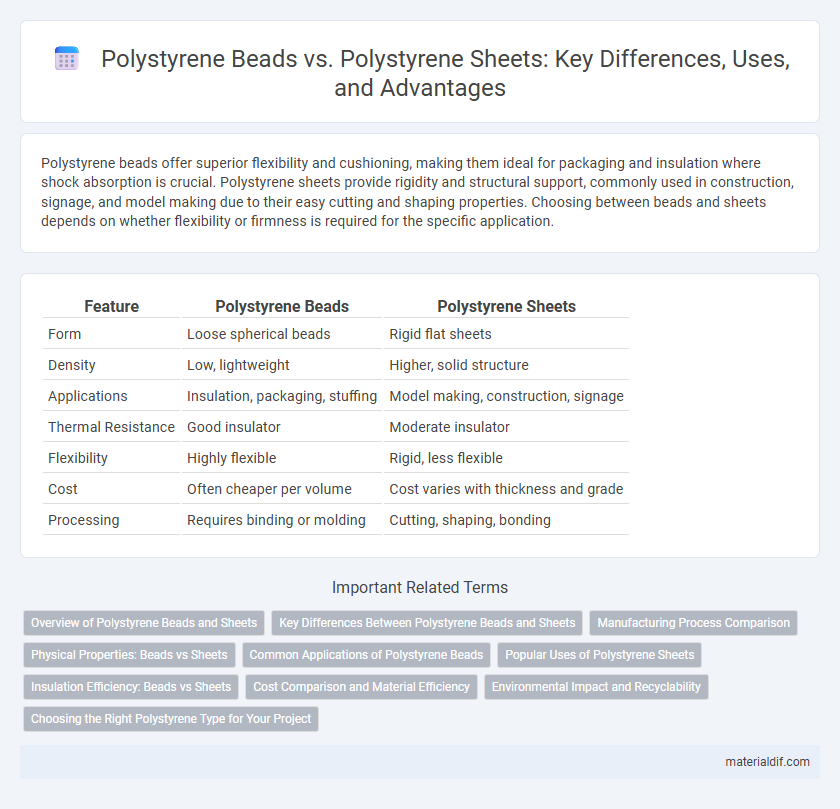

Polystyrene beads offer superior flexibility and cushioning, making them ideal for packaging and insulation where shock absorption is crucial. Polystyrene sheets provide rigidity and structural support, commonly used in construction, signage, and model making due to their easy cutting and shaping properties. Choosing between beads and sheets depends on whether flexibility or firmness is required for the specific application.

Table of Comparison

| Feature | Polystyrene Beads | Polystyrene Sheets |

|---|---|---|

| Form | Loose spherical beads | Rigid flat sheets |

| Density | Low, lightweight | Higher, solid structure |

| Applications | Insulation, packaging, stuffing | Model making, construction, signage |

| Thermal Resistance | Good insulator | Moderate insulator |

| Flexibility | Highly flexible | Rigid, less flexible |

| Cost | Often cheaper per volume | Cost varies with thickness and grade |

| Processing | Requires binding or molding | Cutting, shaping, bonding |

Overview of Polystyrene Beads and Sheets

Polystyrene beads are small, lightweight granules primarily used for insulation, packaging, and crafting applications due to their high expansion capability and excellent shock absorption. Polystyrene sheets, by contrast, are rigid, flat panels commonly utilized in construction, signage, and model building, valued for their structural strength and smooth surface finish. Both forms of polystyrene are versatile, with beads offering flexibility and cushioning, while sheets provide durability and ease of handling.

Key Differences Between Polystyrene Beads and Sheets

Polystyrene beads offer superior insulation and cushioning properties due to their lightweight, expandable nature, making them ideal for packaging and insulation materials. In contrast, polystyrene sheets provide rigidity and structural strength, commonly used in signage, model building, and construction applications. The key differences lie in form, density, and mechanical properties, with beads being porous and flexible, while sheets are solid and firm.

Manufacturing Process Comparison

Polystyrene beads are produced through suspension polymerization, where styrene monomers polymerize into small spherical particles, enabling flexibility in molding and expansion processes. In contrast, polystyrene sheets are typically manufactured by extruding molten polystyrene into flat, uniform layers or by casting, offering consistent thickness and surface finish. The bead production emphasizes granularity and expansion potential, while sheet manufacturing focuses on thermal and mechanical uniformity for structural applications.

Physical Properties: Beads vs Sheets

Polystyrene beads exhibit a lightweight, granular form with excellent insulation and cushioning properties, making them ideal for packaging and craft applications. Polystyrene sheets, in contrast, offer rigidity, smooth surfaces, and structural strength suitable for signage, model making, and construction panels. The density and thermal conductivity of sheets are higher compared to beads, resulting in increased durability but less flexibility.

Common Applications of Polystyrene Beads

Polystyrene beads are commonly used in insulation products, packaging materials, and lightweight filler in bean bags due to their excellent thermal resistance and cushioning properties. These beads provide superior shock absorption and flexibility compared to polystyrene sheets, making them ideal for protective packaging and construction applications. In contrast, polystyrene sheets are primarily utilized for rigid insulation panels, model making, and signage where structural integrity and flat surfaces are required.

Popular Uses of Polystyrene Sheets

Polystyrene sheets are widely used in construction and insulation due to their excellent thermal resistance and moisture barrier properties. These sheets are favored for applications such as wall insulation, packaging, and craft projects because they offer structural rigidity and ease of cutting into various shapes. Compared to polystyrene beads, sheets provide a solid form that enhances durability and support in architectural and design contexts.

Insulation Efficiency: Beads vs Sheets

Polystyrene beads offer superior insulation efficiency due to their ability to fill irregular spaces and provide enhanced thermal resistance through trapped air pockets. In contrast, polystyrene sheets provide a uniform barrier with consistent thickness, making them ideal for applications requiring structural rigidity and ease of installation. The choice between beads and sheets depends on the insulation requirements, with beads excelling in gap-filling and sheets in surface coverage.

Cost Comparison and Material Efficiency

Polystyrene beads generally offer a lower initial cost compared to polystyrene sheets due to their lightweight nature and reduced manufacturing expenses, making them ideal for bulk applications. In terms of material efficiency, sheets provide better structural integrity and consistent thickness, which reduces waste in precise cutting and fabrication processes. Cost-effectiveness depends on the specific use case, with beads preferred for insulation and cushioning, while sheets excel in construction and detailed design projects.

Environmental Impact and Recyclability

Polystyrene beads generate more environmental waste due to their lightweight, fragmented form, which complicates collection and recycling processes compared to polystyrene sheets. Polystyrene sheets, being denser and easier to compact, facilitate more efficient recycling and reduce the likelihood of environmental contamination. Both forms are recyclable, but sheets offer better sustainability potential due to streamlined waste management and higher material recovery rates.

Choosing the Right Polystyrene Type for Your Project

Polystyrene beads offer excellent insulation and flexibility, making them ideal for lightweight packaging, crafts, and model building, while polystyrene sheets provide rigid structural support suited for signage, architectural models, and protective barriers. Selecting the right polystyrene type depends on project requirements such as the need for durability, rigidity, or malleability, with beads excelling in cushioning and sheets in stability. Understanding the density, thermal resistance, and form factor of each polystyrene type ensures optimal performance and cost-efficiency in your application.

Polystyrene Beads vs Polystyrene Sheets Infographic

materialdif.com

materialdif.com