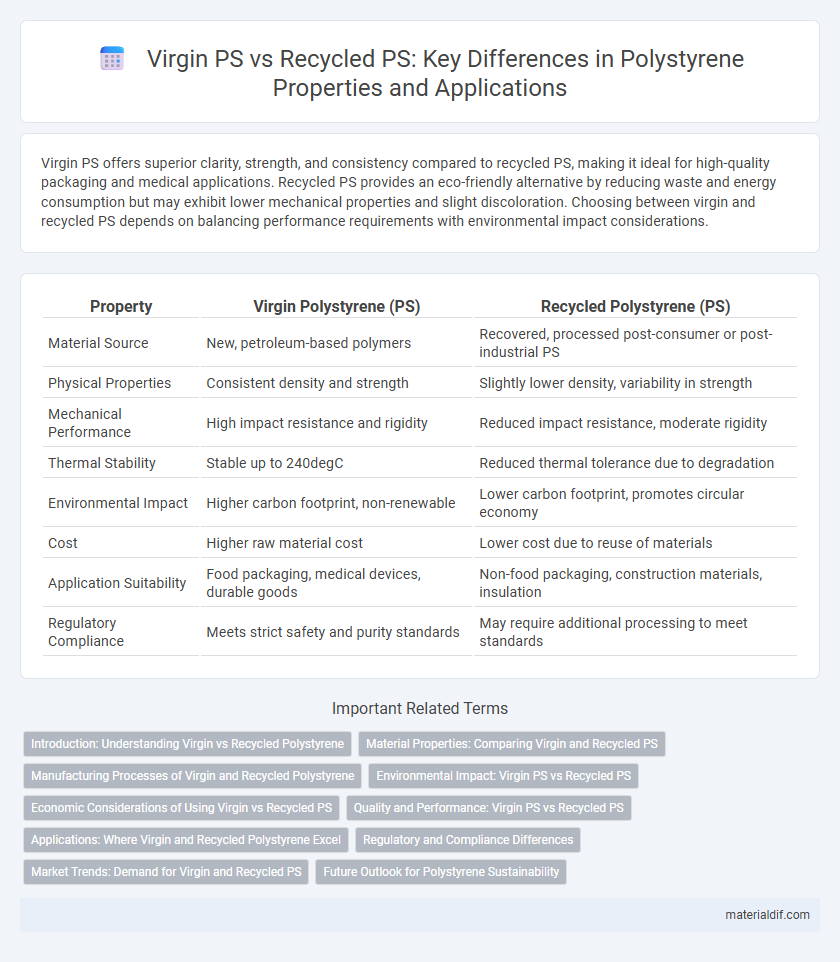

Virgin PS offers superior clarity, strength, and consistency compared to recycled PS, making it ideal for high-quality packaging and medical applications. Recycled PS provides an eco-friendly alternative by reducing waste and energy consumption but may exhibit lower mechanical properties and slight discoloration. Choosing between virgin and recycled PS depends on balancing performance requirements with environmental impact considerations.

Table of Comparison

| Property | Virgin Polystyrene (PS) | Recycled Polystyrene (PS) |

|---|---|---|

| Material Source | New, petroleum-based polymers | Recovered, processed post-consumer or post-industrial PS |

| Physical Properties | Consistent density and strength | Slightly lower density, variability in strength |

| Mechanical Performance | High impact resistance and rigidity | Reduced impact resistance, moderate rigidity |

| Thermal Stability | Stable up to 240degC | Reduced thermal tolerance due to degradation |

| Environmental Impact | Higher carbon footprint, non-renewable | Lower carbon footprint, promotes circular economy |

| Cost | Higher raw material cost | Lower cost due to reuse of materials |

| Application Suitability | Food packaging, medical devices, durable goods | Non-food packaging, construction materials, insulation |

| Regulatory Compliance | Meets strict safety and purity standards | May require additional processing to meet standards |

Introduction: Understanding Virgin vs Recycled Polystyrene

Virgin polystyrene is produced directly from petrochemical raw materials, ensuring consistent purity and mechanical properties ideal for high-performance applications. Recycled polystyrene is derived from post-consumer or post-industrial waste, offering environmental benefits by reducing landfill use and conserving raw resources. Differences in molecular weight and contamination levels influence the processing characteristics and durability of recycled PS compared to virgin material.

Material Properties: Comparing Virgin and Recycled PS

Virgin polystyrene (PS) offers superior mechanical strength, clarity, and thermal stability compared to recycled PS, which may exhibit reduced impact resistance and slight discoloration due to polymer degradation. Recycled PS often contains impurities and altered molecular weights that affect its rigidity and chemical resistance, limiting its suitability for high-performance applications. Despite these variations, advancements in recycling technology help improve the quality and consistency of recycled PS, promoting sustainable material use while balancing performance trade-offs.

Manufacturing Processes of Virgin and Recycled Polystyrene

Virgin polystyrene is produced through the polymerization of styrene monomers derived from petrochemical raw materials, utilizing processes such as bulk, suspension, or emulsion polymerization to achieve high purity and consistent molecular weight. Recycled polystyrene, on the other hand, undergoes mechanical recycling involving collection, sorting, cleaning, shredding, and re-melting, often combined with additives to restore material properties, though it may exhibit inferior mechanical strength and purity. Manufacturing recycled PS also includes chemical recycling methods like depolymerization, which break the polymer back into styrene monomers for repolymerization, offering improved quality but requiring more complex processing steps.

Environmental Impact: Virgin PS vs Recycled PS

Virgin polystyrene (PS) production significantly contributes to carbon emissions and non-renewable fossil fuel consumption due to its reliance on raw petrochemical resources. Recycled PS reduces environmental impact by lowering greenhouse gas emissions and diverting waste from landfills, promoting resource efficiency in circular economy models. However, recycled PS may have limitations in quality and contamination, affecting its potential applications compared to virgin PS.

Economic Considerations of Using Virgin vs Recycled PS

Virgin polystyrene (PS) offers consistent quality and superior mechanical properties, resulting in higher market value and greater demand in high-performance applications. Recycled PS, while cost-effective and environmentally beneficial, often entails additional processing costs and quality variability that can limit its use and profitability. Economics of using virgin versus recycled PS hinge on balancing raw material expenses, processing costs, and end-product application requirements.

Quality and Performance: Virgin PS vs Recycled PS

Virgin polystyrene offers superior clarity, strength, and consistency compared to recycled PS, which may contain impurities and degraded polymer chains affecting its mechanical properties. The performance of recycled polystyrene is often lower in impact resistance and thermal stability, limiting its applications in high-precision or food-grade products. Advances in recycling technology improve recycled PS quality, but virgin PS remains the benchmark for applications demanding optimal purity and reliability.

Applications: Where Virgin and Recycled Polystyrene Excel

Virgin polystyrene (PS) excels in applications requiring high clarity, strength, and purity, such as food packaging, medical devices, and consumer electronics housings. Recycled polystyrene is ideal for non-food contact products like insulation panels, plastic lumber, and automotive components where material consistency and cost-effectiveness are prioritized over optical clarity. Both materials contribute significantly to circular economy goals by optimizing performance in their respective application domains.

Regulatory and Compliance Differences

Virgin polystyrene (PS) complies with stringent regulations such as FDA 21 CFR 177.1640 for food contact applications, ensuring purity and consistent chemical composition. Recycled PS often faces variability in trace contaminants, requiring rigorous testing to meet compliance standards like REACH and California Proposition 65. Regulatory agencies emphasize verification of recycled PS for restricted substances, affecting its suitability in sensitive markets.

Market Trends: Demand for Virgin and Recycled PS

Demand for virgin polystyrene (PS) remains strong due to its superior material properties and applications in food packaging and medical devices. However, the market for recycled PS is rapidly expanding, driven by increasing environmental regulations and consumer preference for sustainable products. Innovations in recycling technologies are enhancing the quality of recycled PS, making it more competitive with virgin PS in various industrial sectors.

Future Outlook for Polystyrene Sustainability

Virgin polystyrene (PS) offers consistent quality and performance but poses environmental challenges due to its reliance on fossil fuels and limited biodegradability. Recycled PS is gaining traction as advanced sorting and chemical recycling technologies improve, enabling higher-quality secondary raw materials that reduce carbon footprints. Industry trends indicate an increasing shift toward circular economy models, with innovations aiming at enhancing PS recyclability and integrating bio-based feedstocks to ensure long-term sustainability in packaging and insulation markets.

Virgin PS vs Recycled PS Infographic

materialdif.com

materialdif.com