Polystyrene packaging offers lightweight, durable protection ideal for shipping fragile items, while polystyrene insulation provides excellent thermal resistance to improve energy efficiency in buildings. Packaging polystyrene is typically thinner and designed to absorb shocks, whereas insulation polystyrene is denser and engineered to reduce heat transfer. Both types utilize expanded or extruded polystyrene but serve distinct purposes that optimize their respective applications.

Table of Comparison

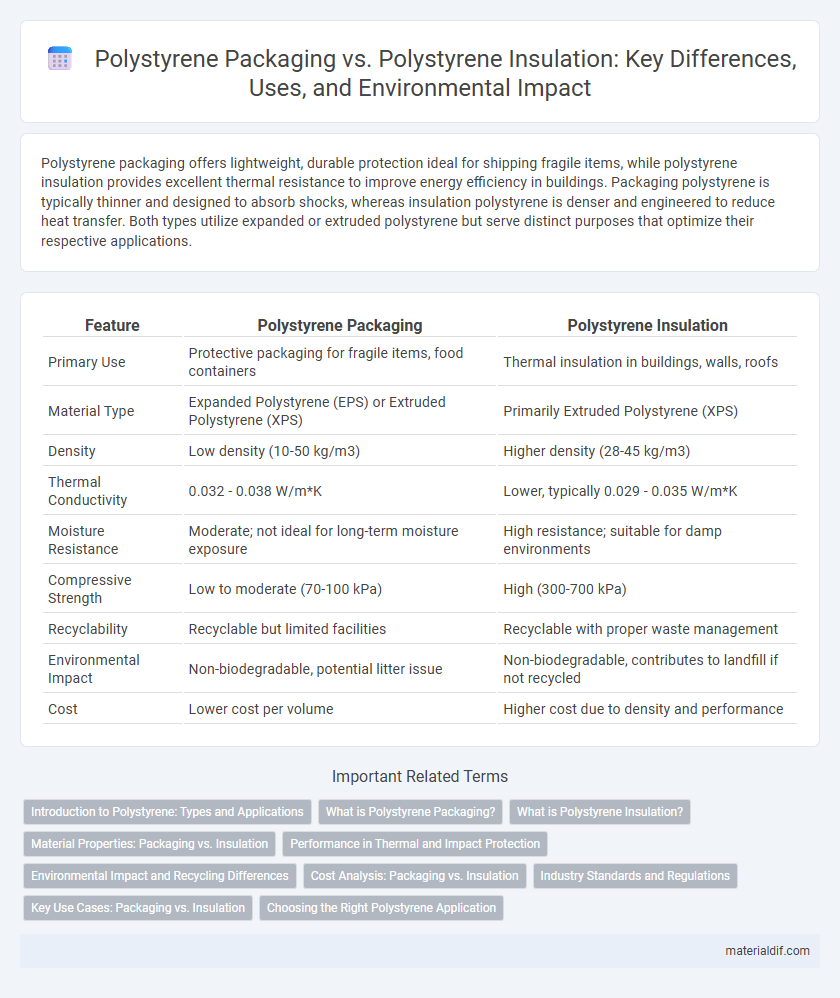

| Feature | Polystyrene Packaging | Polystyrene Insulation |

|---|---|---|

| Primary Use | Protective packaging for fragile items, food containers | Thermal insulation in buildings, walls, roofs |

| Material Type | Expanded Polystyrene (EPS) or Extruded Polystyrene (XPS) | Primarily Extruded Polystyrene (XPS) |

| Density | Low density (10-50 kg/m3) | Higher density (28-45 kg/m3) |

| Thermal Conductivity | 0.032 - 0.038 W/m*K | Lower, typically 0.029 - 0.035 W/m*K |

| Moisture Resistance | Moderate; not ideal for long-term moisture exposure | High resistance; suitable for damp environments |

| Compressive Strength | Low to moderate (70-100 kPa) | High (300-700 kPa) |

| Recyclability | Recyclable but limited facilities | Recyclable with proper waste management |

| Environmental Impact | Non-biodegradable, potential litter issue | Non-biodegradable, contributes to landfill if not recycled |

| Cost | Lower cost per volume | Higher cost due to density and performance |

Introduction to Polystyrene: Types and Applications

Polystyrene is a versatile polymer used extensively in both packaging and insulation due to its lightweight and thermal properties. Expanded polystyrene (EPS) and extruded polystyrene (XPS) are the primary types, with EPS commonly utilized for protective packaging and XPS favored for high-performance insulation in construction. Its applications range from food containers and disposable cutlery in packaging to wall, roof, and foundation insulation in building projects, highlighting its adaptability across industries.

What is Polystyrene Packaging?

Polystyrene packaging refers to the use of expanded or extruded polystyrene foam materials to protect and contain products during shipping and storage. This lightweight, durable material provides excellent cushioning and moisture resistance, making it ideal for packaging electronics, food, and fragile items. Unlike polystyrene insulation, which primarily serves thermal regulation in buildings, polystyrene packaging focuses on product safety and impact absorption.

What is Polystyrene Insulation?

Polystyrene insulation is a rigid foam material used primarily in building construction to improve energy efficiency by providing thermal resistance. It comes in two main types: expanded polystyrene (EPS) and extruded polystyrene (XPS), both characterized by their moisture resistance and high insulation value measured by R-value. Unlike polystyrene packaging, which is designed for cushioning and protection, polystyrene insulation serves as a durable barrier against heat transfer in walls, roofs, and foundations.

Material Properties: Packaging vs. Insulation

Polystyrene packaging utilizes expanded polystyrene (EPS) known for its lightweight, cushioning properties and impact resistance, making it ideal for protecting goods during transit. In contrast, polystyrene insulation employs extruded polystyrene (XPS) which offers higher compressive strength, moisture resistance, and thermal insulation efficiency, crucial for building envelope applications. The distinct material structures of EPS and XPS directly influence their suitability for packaging versus insulation roles based on durability and thermal performance criteria.

Performance in Thermal and Impact Protection

Polystyrene packaging provides excellent impact protection due to its lightweight and shock-absorbing properties, making it ideal for safeguarding fragile items during transport. In contrast, polystyrene insulation excels in thermal performance, offering high R-values that enhance energy efficiency by reducing heat transfer in buildings. While both applications benefit from polystyrene's durability, packaging prioritizes mechanical cushioning, whereas insulation focuses on maintaining stable indoor temperatures.

Environmental Impact and Recycling Differences

Polystyrene packaging, often used for disposable food containers and cushioning materials, typically has a higher contamination rate, limiting its recyclability and increasing landfill accumulation compared to polystyrene insulation, which is sourced from rigid foam boards with more efficient collection systems and recycling processes. Insulation polystyrene products generally have a longer lifecycle and provide energy-saving benefits that offset their environmental impact by reducing building energy consumption. Recycling infrastructure for polystyrene insulation focuses on mechanical or chemical recycling methods that recover foamed materials, whereas packaging polystyrene is less economically viable to recycle due to contamination and density challenges.

Cost Analysis: Packaging vs. Insulation

Polystyrene packaging typically incurs lower initial costs due to lightweight material and mass production efficiencies, making it ideal for single-use applications. In contrast, polystyrene insulation demands higher upfront investment because of its density and thermal performance specifications, but it provides long-term energy savings that reduce overall expenses. Evaluating cost-effectiveness depends on balancing short-term expenditure against extended energy conservation benefits in building applications.

Industry Standards and Regulations

Polystyrene packaging and polystyrene insulation are governed by distinct industry standards and regulations to ensure safety and performance. Polystyrene packaging must comply with FDA regulations for food contact materials, as well as ASTM D6400 for compostability when applicable, whereas polystyrene insulation adheres to ASTM C578 for thermal performance and fire safety requirements under building codes such as the International Building Code (IBC). Regulatory oversight also includes environmental restrictions, with packaging subject to waste management rules like the EPA's Resource Conservation and Recovery Act (RCRA), while insulation standards emphasize long-term durability and thermal resistance.

Key Use Cases: Packaging vs. Insulation

Polystyrene packaging excels in protecting fragile goods during transportation, offering lightweight, shock-absorbing properties that reduce shipping costs and product damage. In contrast, polystyrene insulation is widely used in building construction and refrigeration, providing superior thermal resistance with high R-values that enhance energy efficiency. While packaging applications prioritize impact protection and cushioning, insulation leverages polystyrene's low thermal conductivity to maintain temperature control and reduce energy consumption.

Choosing the Right Polystyrene Application

Polystyrene packaging offers lightweight, shock-absorbing properties ideal for protecting fragile goods during shipping, while polystyrene insulation provides excellent thermal resistance with an R-value of approximately 4 per inch, making it effective for energy-efficient building applications. Selecting the right polystyrene application depends on factors such as durability requirements, environmental exposure, and insulating performance needs. For shipping fragile items, expanded polystyrene (EPS) foam is preferred, whereas extruded polystyrene (XPS) is more suitable for long-term insulation due to its moisture resistance and compressive strength.

Polystyrene Packaging vs Polystyrene Insulation Infographic

materialdif.com

materialdif.com