Biodegradable foams, made from natural materials like cornstarch or cellulose, offer an eco-friendly alternative to synthetic foams such as polystyrene commonly used in PET packaging. These biodegradable options break down more rapidly in the environment, reducing plastic pollution and landfill waste. Synthetic foams, while durable and cost-effective, pose long-term ecological risks due to their resistance to decomposition and potential release of harmful substances.

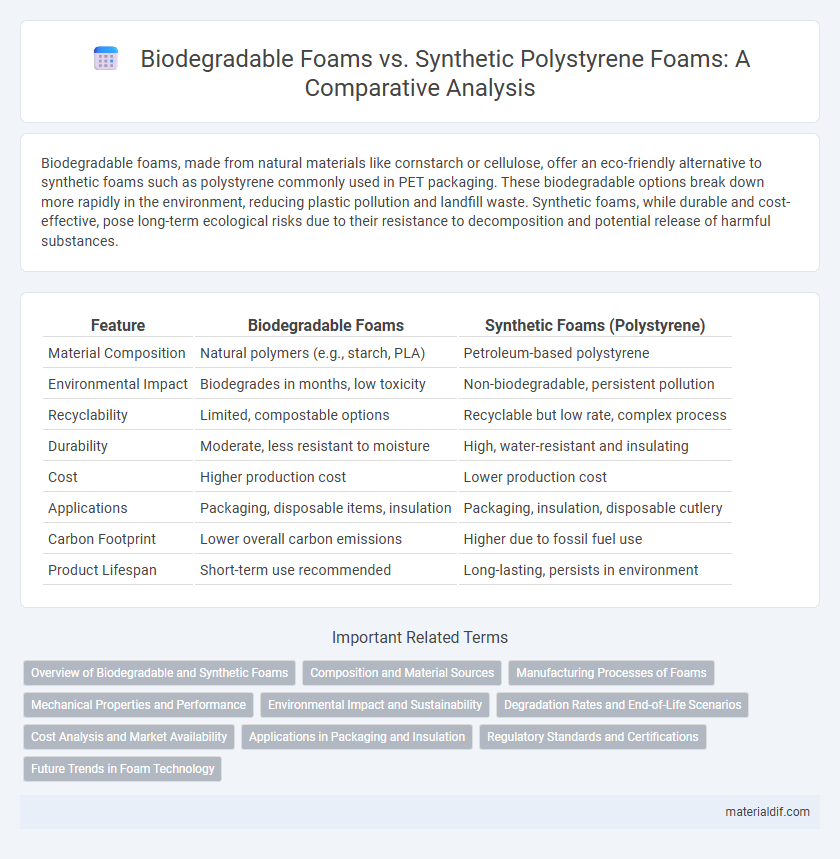

Table of Comparison

| Feature | Biodegradable Foams | Synthetic Foams (Polystyrene) |

|---|---|---|

| Material Composition | Natural polymers (e.g., starch, PLA) | Petroleum-based polystyrene |

| Environmental Impact | Biodegrades in months, low toxicity | Non-biodegradable, persistent pollution |

| Recyclability | Limited, compostable options | Recyclable but low rate, complex process |

| Durability | Moderate, less resistant to moisture | High, water-resistant and insulating |

| Cost | Higher production cost | Lower production cost |

| Applications | Packaging, disposable items, insulation | Packaging, insulation, disposable cutlery |

| Carbon Footprint | Lower overall carbon emissions | Higher due to fossil fuel use |

| Product Lifespan | Short-term use recommended | Long-lasting, persists in environment |

Overview of Biodegradable and Synthetic Foams

Biodegradable foams, derived from natural polymers such as starch, polylactic acid (PLA), and cellulose, decompose through microbial activity, reducing environmental impact compared to synthetic foams made from petroleum-based polymers like polystyrene and polyurethane. Synthetic foams offer superior insulation, durability, and cost-effectiveness but contribute significantly to plastic pollution and landfill waste due to their resistance to degradation. The growing demand for sustainable materials drives innovation in biodegradable foam formulations to match the performance characteristics of synthetic foams while enhancing eco-friendly disposal.

Composition and Material Sources

Biodegradable foams are primarily composed of natural polymers such as starch, cellulose, and polylactic acid (PLA), derived from renewable resources like corn, sugarcane, and other plant-based materials. Synthetic foams, including polystyrene and polyurethane, are produced from petrochemical resources through polymerization processes involving styrene monomers and isocyanates. The key difference lies in the biodegradability of natural polymer-based foams versus the long-lasting synthetic polymers derived from fossil fuels.

Manufacturing Processes of Foams

Biodegradable foams are typically produced using renewable polymers such as polylactic acid (PLA) through processes like extrusion and injection molding, which emphasize eco-friendly raw materials and lower emissions. Synthetic foams, primarily made from polystyrene, involve polymerization of styrene monomers followed by chemical or physical blowing agents to create foam structures, requiring significant energy input and petrochemical resources. Manufacturing biodegradable foams often prioritizes compostability and reduced environmental impact, whereas synthetic foam production focuses on cost-effectiveness and material performance.

Mechanical Properties and Performance

Biodegradable foams, such as those derived from polylactic acid (PLA) or starch-based materials, often exhibit lower tensile strength and impact resistance compared to synthetic foams like polystyrene and polyurethane. Synthetic foams provide superior mechanical properties including higher compressive strength, elasticity, and durability, making them more suitable for applications demanding long-term performance and structural integrity. However, advancements in biodegradable foam formulations are progressively enhancing their mechanical performance, narrowing the gap with traditional synthetic foams in specialized uses.

Environmental Impact and Sustainability

Biodegradable foams, derived from natural polymers such as polylactic acid or starch, break down more rapidly in the environment, reducing long-term pollution compared to synthetic foams like polystyrene which persist for centuries. The production of biodegradable foams typically involves renewable resources and lower carbon emissions, enhancing sustainability credentials while synthetic foam manufacturing relies heavily on petrochemicals and energy-intensive processes. Although biodegradable foams currently have limitations in durability and cost, their reduced environmental impact positions them as a preferable alternative for sustainable packaging and insulation solutions.

Degradation Rates and End-of-Life Scenarios

Biodegradable foams derived from polylactic acid (PLA) or starch blends exhibit degradation rates within months under industrial composting conditions, contrasting sharply with synthetic polystyrene foams that persist for centuries in landfills or marine environments. End-of-life scenarios for biodegradable foams often involve composting or anaerobic digestion, enabling carbon cycling back into the ecosystem, whereas synthetic polystyrene foams primarily rely on landfill disposal or costly recycling processes with low recovery efficiency. The disparity in degradation kinetics and waste management options significantly impacts environmental footprint and informs material selection in sustainable packaging solutions.

Cost Analysis and Market Availability

Biodegradable foams, typically derived from natural polymers like polylactic acid (PLA), exhibit higher production costs compared to synthetic foams such as polystyrene, primarily due to raw material expenses and processing complexities. Market availability of biodegradable foams remains limited, with a smaller scale of manufacturing infrastructure and less widespread distribution channels than the well-established synthetic foam industry. Cost analysis shows synthetic polystyrene foams dominate sectors like packaging and insulation due to lower price points and mass availability, despite growing demand for sustainable alternatives.

Applications in Packaging and Insulation

Biodegradable foams derived from renewable resources are increasingly favored in packaging and insulation applications due to their eco-friendly disposal and reduced environmental impact compared to traditional synthetic foams like polystyrene. Synthetic foams provide superior thermal insulation and cushioning properties, making them prevalent in packaging fragile electronics and effective in building insulation. The choice between biodegradable and synthetic foams depends on balancing sustainability goals with performance requirements such as durability, moisture resistance, and cost-effectiveness.

Regulatory Standards and Certifications

Biodegradable foams are subject to rigorous regulatory standards such as ASTM D6400 and EN 13432, which certify their compostability and environmental impact, unlike conventional synthetic polystyrene foams that often lack biodegradability certifications and face increasing regulatory restrictions due to their persistence in the environment. Regulatory agencies like the EPA and EU REACH prioritize the reduction of non-biodegradable waste, promoting biodegradable foam alternatives that meet strict biodegradation timelines and toxicity thresholds. Certifications from organizations like BPI (Biodegradable Products Institute) and TUV Austria provide market validation for biodegradable foams, distinguishing them from synthetic foams under evolving sustainability mandates.

Future Trends in Foam Technology

Biodegradable foams are gaining traction as sustainable alternatives to synthetic foams, driven by advancements in bio-based polymers and green chemistry. Innovations focus on enhancing mechanical properties and thermal insulation while ensuring complete compostability, responding to escalating environmental regulations worldwide. Emerging trends include the integration of nanocellulose and biopolyester blends, targeting higher performance and reduced carbon footprints for future foam applications.

Biodegradable Foams vs Synthetic Foams Infographic

materialdif.com

materialdif.com