Extruded Polystyrene (XPS) offers higher compressive strength and moisture resistance compared to Expanded Polystyrene (EPS), making it ideal for use in construction insulation and packaging where durability is critical. EPS, characterized by its lightweight and cost-effectiveness, excels in applications requiring thermal insulation with less exposure to mechanical stress. Choosing between XPS and EPS depends on the specific performance needs, balancing factors such as insulation efficiency, cost, and environmental exposure.

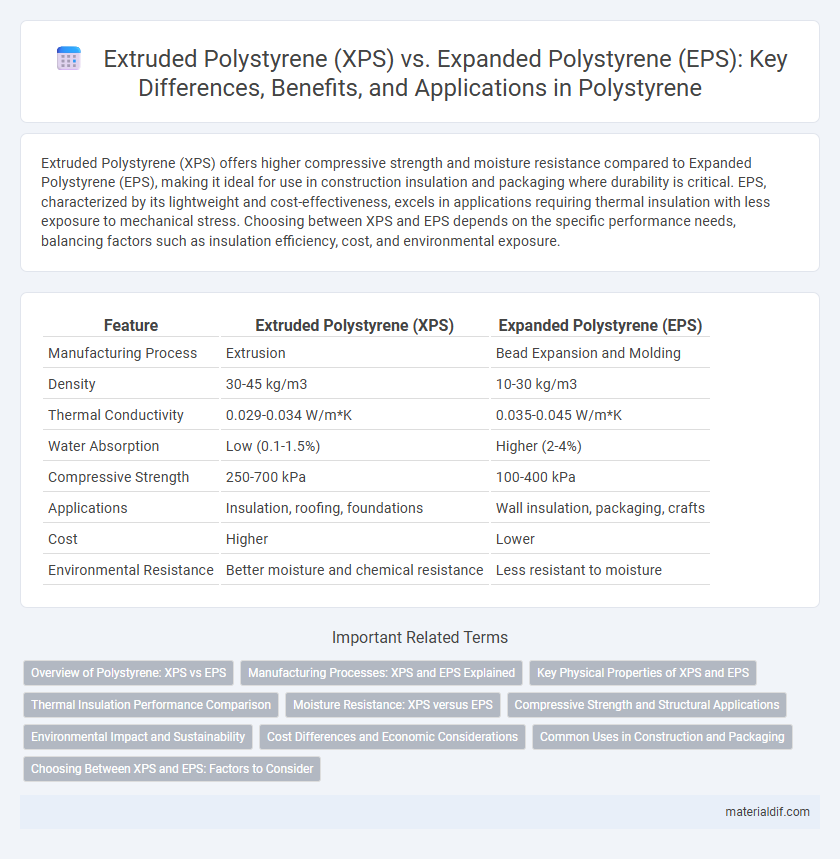

Table of Comparison

| Feature | Extruded Polystyrene (XPS) | Expanded Polystyrene (EPS) |

|---|---|---|

| Manufacturing Process | Extrusion | Bead Expansion and Molding |

| Density | 30-45 kg/m3 | 10-30 kg/m3 |

| Thermal Conductivity | 0.029-0.034 W/m*K | 0.035-0.045 W/m*K |

| Water Absorption | Low (0.1-1.5%) | Higher (2-4%) |

| Compressive Strength | 250-700 kPa | 100-400 kPa |

| Applications | Insulation, roofing, foundations | Wall insulation, packaging, crafts |

| Cost | Higher | Lower |

| Environmental Resistance | Better moisture and chemical resistance | Less resistant to moisture |

Overview of Polystyrene: XPS vs EPS

Extruded Polystyrene (XPS) and Expanded Polystyrene (EPS) are both rigid foam insulation materials derived from polystyrene, yet they differ significantly in manufacturing processes and performance characteristics. XPS is produced through an extrusion process, yielding a denser, more moisture-resistant material with higher compressive strength, making it ideal for structural applications. In contrast, EPS is created by expanding beads with steam, resulting in a lighter, more cost-effective product with lower thermal resistance and durability, commonly used for packaging and non-load-bearing insulation.

Manufacturing Processes: XPS and EPS Explained

Extruded Polystyrene (XPS) is manufactured through a continuous extrusion process that melts polystyrene resin with blowing agents to create a dense, closed-cell foam with uniform cell structure. Expanded Polystyrene (EPS) is produced by pre-expanding beads with steam, then molding and fusing them into large blocks, resulting in a lighter, open-cell foam with variable density. The manufacturing process of XPS allows for higher insulation performance and moisture resistance compared to EPS, which is more cost-effective and versatile in various applications.

Key Physical Properties of XPS and EPS

Extruded Polystyrene (XPS) exhibits higher compressive strength and lower water absorption compared to Expanded Polystyrene (EPS), making it ideal for insulation in high-moisture environments. EPS features a lower density and better vapor permeability, contributing to superior breathability but reduced durability under prolonged pressure. Thermal conductivity values for XPS typically range from 0.029 to 0.034 W/m*K, while EPS ranges from 0.032 to 0.038 W/m*K, indicating XPS offers enhanced insulating performance.

Thermal Insulation Performance Comparison

Extruded Polystyrene (XPS) offers a higher thermal insulation value with R-values typically around 5 per inch, compared to Expanded Polystyrene (EPS), which usually ranges from 3.6 to 4.2 per inch. XPS features a closed-cell structure that enhances moisture resistance and long-term durability, contributing to more consistent thermal performance over time. EPS, while cost-effective and versatile, has a more open-cell structure that can absorb moisture, potentially reducing its insulating properties in damp environments.

Moisture Resistance: XPS versus EPS

Extruded Polystyrene (XPS) exhibits superior moisture resistance compared to Expanded Polystyrene (EPS) due to its dense, closed-cell structure that effectively limits water absorption and vapor diffusion. XPS typically has water absorption rates below 1%, making it ideal for applications requiring long-term exposure to moisture, such as below-grade insulation and roofing. In contrast, EPS has a more open cell structure with higher porosity, resulting in increased water uptake and reduced thermal performance when exposed to wet conditions.

Compressive Strength and Structural Applications

Extruded Polystyrene (XPS) exhibits higher compressive strength, typically ranging from 20 to 35 psi, making it well-suited for structural applications such as insulation beneath concrete slabs and in roofing systems. Expanded Polystyrene (EPS) has lower compressive strength, generally between 10 to 15 psi, limiting its use to less demanding load-bearing insulation roles. The denser, closed-cell structure of XPS provides superior durability and resistance to moisture, enhancing its performance in structural environments compared to the more porous EPS.

Environmental Impact and Sustainability

Extruded Polystyrene (XPS) typically has a higher environmental footprint compared to Expanded Polystyrene (EPS) due to its production process involving more energy-intensive extrusion and the use of blowing agents with higher global warming potential. EPS is generally considered more sustainable as it contains a higher percentage of recycled content and is easier to recycle, reducing landfill waste. Both materials are widely used for insulation, but choosing EPS can contribute to lower carbon emissions and improved waste management in construction projects.

Cost Differences and Economic Considerations

Extruded Polystyrene (XPS) generally costs more than Expanded Polystyrene (EPS) due to its denser structure and superior insulating properties, influencing initial investment decisions. EPS offers a more economical option for large-scale applications where budget constraints are critical, despite its lower compressive strength and moisture resistance compared to XPS. Long-term economic considerations favor XPS in projects requiring enhanced durability and energy efficiency, potentially reducing maintenance and energy costs over time.

Common Uses in Construction and Packaging

Extruded Polystyrene (XPS) is commonly used in construction for roof insulation, foundation walls, and below-grade applications due to its high compressive strength and moisture resistance. Expanded Polystyrene (EPS) is widely utilized in packaging for protecting fragile items and in construction for thermal insulation in walls and under slabs because of its lightweight and cost-effective properties. Both materials contribute significantly to energy efficiency and product protection across building and packaging industries.

Choosing Between XPS and EPS: Factors to Consider

Selecting between Extruded Polystyrene (XPS) and Expanded Polystyrene (EPS) hinges on insulation needs, moisture resistance, and budget constraints. XPS offers higher compressive strength and superior moisture resistance, making it ideal for applications such as below-grade insulation and roofing, while EPS is more cost-effective and suitable for general insulation where moisture exposure is minimal. Consider thermal conductivity values, durability requirements, and environmental impact to determine the optimal material for specific construction projects.

Extruded Polystyrene (XPS) vs Expanded Polystyrene (EPS) Infographic

materialdif.com

materialdif.com