Foamed polystyrene, also known as expanded polystyrene (EPS), is lightweight with excellent insulation properties due to its air-filled bead structure, making it ideal for packaging and thermal insulation. Extruded polystyrene (XPS) offers higher density and compressive strength, providing superior moisture resistance and durability for construction applications such as rigid foam boards. Both materials serve insulation purposes but differ significantly in mechanical performance and water resistance based on their manufacturing processes.

Table of Comparison

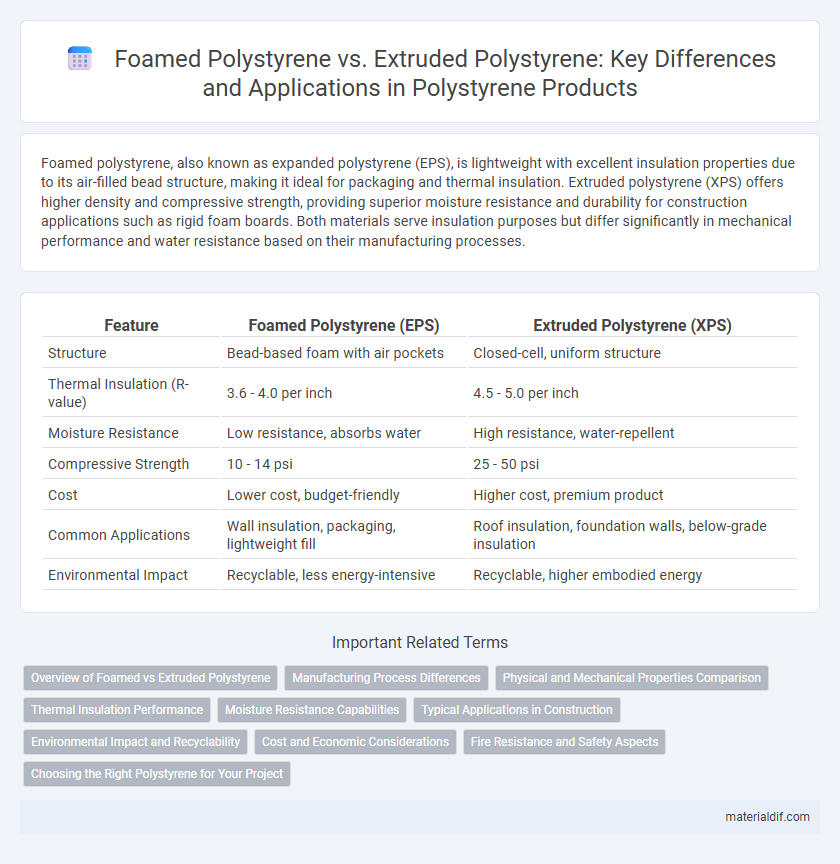

| Feature | Foamed Polystyrene (EPS) | Extruded Polystyrene (XPS) |

|---|---|---|

| Structure | Bead-based foam with air pockets | Closed-cell, uniform structure |

| Thermal Insulation (R-value) | 3.6 - 4.0 per inch | 4.5 - 5.0 per inch |

| Moisture Resistance | Low resistance, absorbs water | High resistance, water-repellent |

| Compressive Strength | 10 - 14 psi | 25 - 50 psi |

| Cost | Lower cost, budget-friendly | Higher cost, premium product |

| Common Applications | Wall insulation, packaging, lightweight fill | Roof insulation, foundation walls, below-grade insulation |

| Environmental Impact | Recyclable, less energy-intensive | Recyclable, higher embodied energy |

Overview of Foamed vs Extruded Polystyrene

Foamed polystyrene (EPS) consists of expanded beads fused together to create a lightweight, rigid insulation material widely used in packaging and construction. Extruded polystyrene (XPS) is manufactured by melting and extruding polystyrene pellets through a die, resulting in a denser, more moisture-resistant foam with higher compressive strength. EPS offers better vapor permeability, while XPS provides superior thermal insulation and durability for applications requiring enhanced structural integrity.

Manufacturing Process Differences

Foamed polystyrene is created by expanding polystyrene beads using steam, causing them to fuse into a lightweight, porous structure ideal for insulation and packaging. Extruded polystyrene undergoes a continuous extrusion process where molten polystyrene is pushed through a die, creating a dense, closed-cell foam with higher structural strength and moisture resistance. The manufacturing differences result in foamed polystyrene having a more open-cell structure, while extruded polystyrene features a uniform, closed-cell composition that enhances its thermal performance and durability.

Physical and Mechanical Properties Comparison

Foamed polystyrene (EPS) exhibits lower density, higher porosity, and reduced compressive strength compared to extruded polystyrene (XPS), which offers a closed-cell structure with superior moisture resistance and higher thermal insulation values. XPS typically delivers greater durability and mechanical stability under load due to its uniform cell structure, making it ideal for load-bearing applications. The compressive strength of XPS can range from 15 to 30 psi, while EPS ranges from 10 to 25 psi, influencing suitability in construction and packaging industries.

Thermal Insulation Performance

Foamed polystyrene (EPS) features a bead structure that provides effective thermal insulation with an R-value typically ranging from 3.6 to 4.0 per inch, making it suitable for general insulation purposes. Extruded polystyrene (XPS) offers a denser, closed-cell structure, delivering higher thermal resistance with R-values usually between 5.0 and 5.5 per inch, resulting in superior moisture resistance and long-term thermal performance. XPS's enhanced insulation efficiency makes it ideal for applications requiring greater durability and consistent thermal protection under moisture exposure.

Moisture Resistance Capabilities

Foamed Polystyrene (EPS) features a bead-based structure that allows water absorption, limiting its moisture resistance, while Extruded Polystyrene (XPS) exhibits a closed-cell, dense composition that significantly reduces water permeability. This structural difference results in XPS maintaining higher R-values and structural integrity in wet conditions compared to EPS. Industry standards report XPS with a water absorption rate typically below 0.3%, making it the preferred choice for applications requiring superior moisture resistance.

Typical Applications in Construction

Foamed polystyrene (EPS) is widely used for thermal insulation in walls, roofs, and under concrete slabs due to its lightweight and cost-effective properties. Extruded polystyrene (XPS) offers higher compressive strength and moisture resistance, making it ideal for below-grade insulation, foundation walls, and roofing boards. Both materials enhance energy efficiency in buildings but are selected based on specific structural and environmental demands.

Environmental Impact and Recyclability

Foamed polystyrene, commonly used in packaging and insulation, tends to have a higher environmental footprint due to its widespread single-use applications and difficulty in recycling, leading to significant landfill accumulation. Extruded polystyrene offers better thermal insulation properties and is more easily recyclable, reducing environmental impact when recycled properly through specialized facilities. Both materials are petroleum-based, but extruded polystyrene's denser structure promotes longer lifespan and potential reuse, lowering overall ecological damage.

Cost and Economic Considerations

Foamed polystyrene typically costs less per cubic meter than extruded polystyrene, making it a more budget-friendly option for large-scale insulation projects. The lower manufacturing complexity and material density contribute to its reduced price, though extruded polystyrene offers better durability and moisture resistance, potentially lowering long-term maintenance expenses. Economic considerations must weigh initial investment against lifespan and performance benefits when selecting between these materials.

Fire Resistance and Safety Aspects

Foamed polystyrene (EPS) typically exhibits lower fire resistance compared to extruded polystyrene (XPS), as EPS tends to ignite more easily and releases more smoke and toxic gases during combustion. XPS features a closed-cell structure that enhances its fire-retardant properties and slows flame spread, making it a safer choice in applications with stringent fire safety requirements. Fire safety standards such as ASTM E84 and UL 723 often rate XPS higher for flame spread and smoke development, contributing to its preference in construction and insulation where enhanced fire resistance is critical.

Choosing the Right Polystyrene for Your Project

Foamed polystyrene, known for its lightweight and excellent insulation properties, is ideal for thermal insulation in walls, roofs, and packaging, offering cost-effectiveness and ease of installation. Extruded polystyrene provides higher compressive strength, moisture resistance, and durability, making it suitable for applications requiring long-term performance under load and exposure to damp conditions, such as foundations and under-slab insulation. Assess project needs related to insulation efficiency, moisture exposure, and mechanical stress to select the appropriate polystyrene type that balances performance and budget.

Foamed Polystyrene vs Extruded Polystyrene Infographic

materialdif.com

materialdif.com