Solid polystyrene offers high rigidity and clarity, making it ideal for durable, transparent applications such as packaging and displays. Foamed polystyrene, characterized by its lightweight and excellent insulation properties, is commonly used in cushioning and thermal insulation. Both forms serve distinct purposes, with solid polystyrene providing structural strength and foamed polystyrene delivering energy absorption and thermal resistance.

Table of Comparison

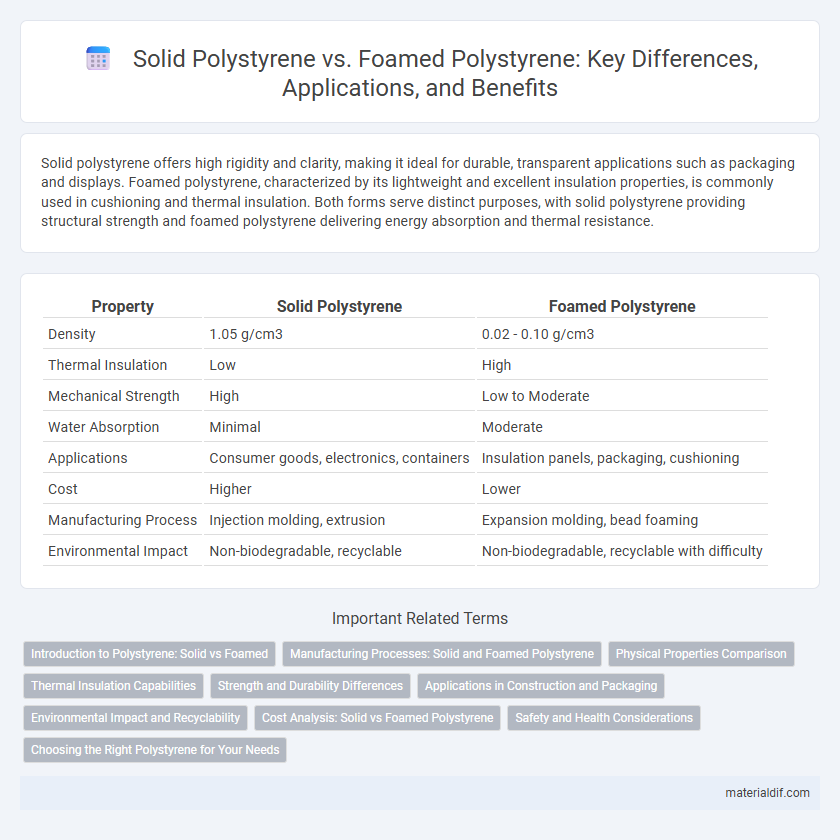

| Property | Solid Polystyrene | Foamed Polystyrene |

|---|---|---|

| Density | 1.05 g/cm3 | 0.02 - 0.10 g/cm3 |

| Thermal Insulation | Low | High |

| Mechanical Strength | High | Low to Moderate |

| Water Absorption | Minimal | Moderate |

| Applications | Consumer goods, electronics, containers | Insulation panels, packaging, cushioning |

| Cost | Higher | Lower |

| Manufacturing Process | Injection molding, extrusion | Expansion molding, bead foaming |

| Environmental Impact | Non-biodegradable, recyclable | Non-biodegradable, recyclable with difficulty |

Introduction to Polystyrene: Solid vs Foamed

Polystyrene exists in two primary forms: solid and foamed, each with distinct physical and chemical properties. Solid polystyrene is a rigid, transparent thermoplastic widely used in packaging, insulation, and consumer products due to its strength and clarity. Foamed polystyrene, also known as expanded polystyrene (EPS), is a lightweight, porous material used primarily for thermal insulation, cushioning, and protective packaging because of its excellent shock absorption and thermal resistance.

Manufacturing Processes: Solid and Foamed Polystyrene

Solid polystyrene is produced through bulk or suspension polymerization, resulting in a dense, rigid material with a smooth surface, ideal for applications requiring structural integrity. Foamed polystyrene is created by expanding polystyrene beads or pellets using blowing agents during polymerization, forming a cellular structure that provides excellent thermal insulation and cushioning properties. Manufacturing foamed polystyrene involves techniques like pre-expansion, aging, and molding, which contribute to its lightweight and versatile nature compared to solid polystyrene.

Physical Properties Comparison

Solid polystyrene exhibits higher density and rigidity, providing greater structural strength and impact resistance compared to foamed polystyrene. Foamed polystyrene contains numerous air pockets, resulting in lower density, enhanced thermal insulation, and improved shock absorption capabilities. The compressive strength of solid polystyrene typically surpasses that of foamed variants, making it suitable for load-bearing applications while foamed polystyrene excels in lightweight packaging and insulating materials.

Thermal Insulation Capabilities

Solid polystyrene offers moderate thermal insulation with a typical R-value around 1.2 per inch, suitable for general applications requiring rigidity. Foamed polystyrene, particularly expanded (EPS) and extruded (XPS) variants, delivers superior thermal resistance, with R-values ranging from 3.6 to 5 per inch due to its air-trapped cellular structure. The enhanced insulation performance of foamed polystyrene makes it ideal for building envelopes, reducing heat transfer and improving energy efficiency.

Strength and Durability Differences

Solid polystyrene exhibits higher tensile strength and superior impact resistance compared to foamed polystyrene, making it more suitable for structural applications requiring durability. Foamed polystyrene, characterized by its lightweight, cellular structure, offers enhanced thermal insulation but compromises mechanical strength due to its porous composition. The density variation between solid (approximately 1050 kg/m3) and foamed polystyrene (typically ranging from 10 to 100 kg/m3) directly influences their respective load-bearing capacities and longevity in different environmental conditions.

Applications in Construction and Packaging

Solid polystyrene offers high durability and structural strength, making it ideal for rigid construction components such as insulation panels and decorative moldings. Foamed polystyrene provides excellent thermal insulation and lightweight cushioning properties, extensively used in packaging fragile items and insulating building envelopes. Both materials leverage their unique physical characteristics to enhance energy efficiency and protection in their respective applications.

Environmental Impact and Recyclability

Solid polystyrene is dense and less porous, making it easier to recycle through mechanical processes, while foamed polystyrene, often used in packaging and insulation, presents greater recycling challenges due to its low density and contamination risks. Foamed polystyrene contributes significantly to landfill volume and marine pollution as it degrades slowly and fragments into microplastics, increasing environmental hazards. Advances in chemical recycling and biodegradable alternatives aim to mitigate the long-term ecological footprint of both solid and foamed polystyrene products.

Cost Analysis: Solid vs Foamed Polystyrene

Solid polystyrene typically incurs higher material costs due to its density and manufacturing process, whereas foamed polystyrene offers significant cost savings attributed to its lightweight, expanded structure that reduces raw material usage. The production energy consumption for foamed polystyrene is lower, resulting in decreased operational expenses and more efficient large-scale manufacturing. Despite higher initial durability, solid polystyrene's elevated expense often limits its application where cost-efficiency and thermal insulation are prioritized, making foamed polystyrene a preferred choice in packaging and construction industries.

Safety and Health Considerations

Solid polystyrene is dense and less prone to releasing harmful particles, reducing inhalation risks, whereas foamed polystyrene contains trapped air bubbles that can degrade into fine dust with potential respiratory hazards. Both materials should be handled with caution during cutting or heating, as they can emit styrene vapor, a possible carcinogen linked to headaches and eye irritation. Proper ventilation and protective equipment are essential to minimize exposure to hazardous styrene monomers and combustion byproducts.

Choosing the Right Polystyrene for Your Needs

Solid polystyrene offers high durability and rigidity, making it ideal for applications requiring structural strength and precision, such as packaging and model making. Foamed polystyrene, characterized by its lightweight and excellent thermal insulation properties, is best suited for construction insulation, protective packaging, and disposable food containers. Evaluating the specific requirements of your project, including strength, insulation needs, and budget, will guide the optimal choice between solid and foamed polystyrene.

Solid Polystyrene vs Foamed Polystyrene Infographic

materialdif.com

materialdif.com