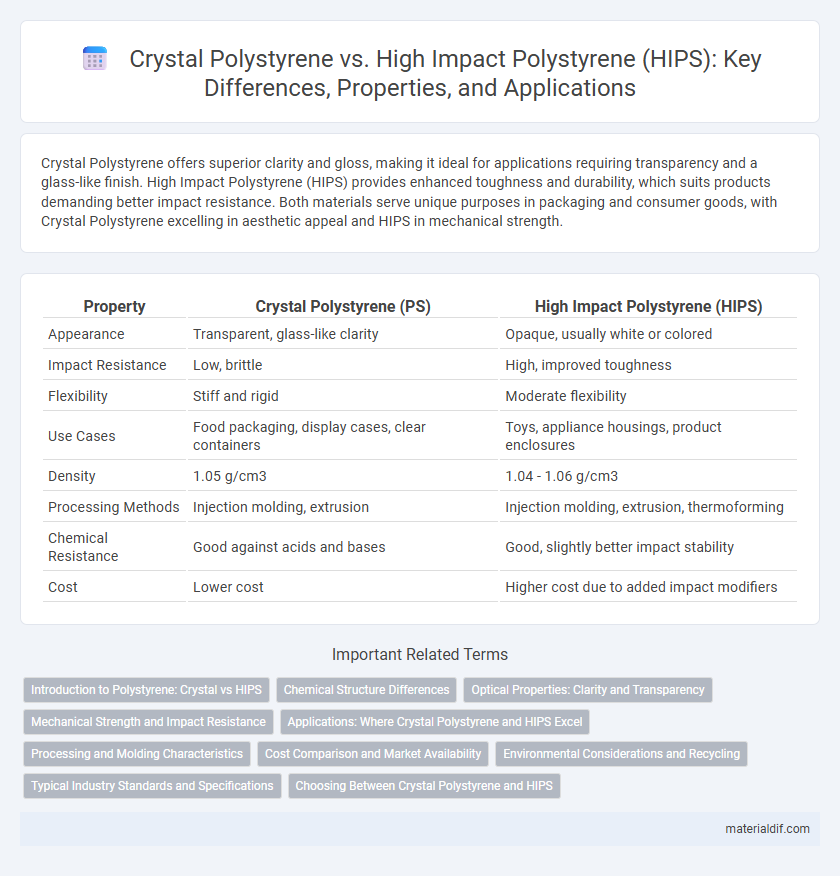

Crystal Polystyrene offers superior clarity and gloss, making it ideal for applications requiring transparency and a glass-like finish. High Impact Polystyrene (HIPS) provides enhanced toughness and durability, which suits products demanding better impact resistance. Both materials serve unique purposes in packaging and consumer goods, with Crystal Polystyrene excelling in aesthetic appeal and HIPS in mechanical strength.

Table of Comparison

| Property | Crystal Polystyrene (PS) | High Impact Polystyrene (HIPS) |

|---|---|---|

| Appearance | Transparent, glass-like clarity | Opaque, usually white or colored |

| Impact Resistance | Low, brittle | High, improved toughness |

| Flexibility | Stiff and rigid | Moderate flexibility |

| Use Cases | Food packaging, display cases, clear containers | Toys, appliance housings, product enclosures |

| Density | 1.05 g/cm3 | 1.04 - 1.06 g/cm3 |

| Processing Methods | Injection molding, extrusion | Injection molding, extrusion, thermoforming |

| Chemical Resistance | Good against acids and bases | Good, slightly better impact stability |

| Cost | Lower cost | Higher cost due to added impact modifiers |

Introduction to Polystyrene: Crystal vs HIPS

Crystal polystyrene offers a clear, glass-like appearance with excellent rigidity and surface gloss, making it ideal for applications requiring transparency such as display cases and packaging. High Impact Polystyrene (HIPS) incorporates rubber to enhance toughness and impact resistance, suited for products demanding durability like appliance housings and toys. These fundamental differences in structure and properties determine their specific industrial uses within the broader category of polystyrene materials.

Chemical Structure Differences

Crystal Polystyrene is a rigid, transparent polymer composed of linear chains of styrene monomers without significant modification, resulting in a pure and brittle material. HIPS (High Impact Polystyrene) incorporates polybutadiene rubber particles within the polystyrene matrix, enhancing toughness by disrupting the uniformity of the chemical structure and absorbing impact energy. The presence of these rubber elastomers in HIPS creates a two-phase system, contrasting with the homogeneous, amorphous structure of Crystal Polystyrene.

Optical Properties: Clarity and Transparency

Crystal Polystyrene offers superior clarity and transparency due to its amorphous structure, making it ideal for applications requiring excellent optical properties like packaging and display products. In contrast, HIPS (High Impact Polystyrene) incorporates rubber modifiers that reduce optical clarity but significantly increase impact resistance and toughness. The choice between Crystal Polystyrene and HIPS depends on the balance between aesthetic transparency and mechanical durability required for specific uses.

Mechanical Strength and Impact Resistance

Crystal Polystyrene offers a high level of rigidity with a tensile strength around 6,000 psi, making it suitable for applications requiring stiffness and clarity, but its impact resistance is relatively low compared to HIPS. High Impact Polystyrene (HIPS) enhances toughness by incorporating rubber particles, providing superior impact resistance with an Izod impact strength approximately 11-15 ft*lbf/in, ideal for products needing durability under stress. Mechanical strength favors CP for stiffness and surface finish, while HIPS excels in applications demanding impact resistance and flexibility.

Applications: Where Crystal Polystyrene and HIPS Excel

Crystal Polystyrene excels in applications requiring high clarity and rigidity, such as clear packaging, display cases, and optical products due to its excellent transparency and surface gloss. HIPS (High Impact Polystyrene) is preferred in impact-resistant applications like appliance housings, automotive parts, and protective packaging, where toughness and durability are critical. Both materials serve distinct roles in industries like consumer goods and electronics, with Crystal Polystyrene focused on visual appeal and HIPS on mechanical performance.

Processing and Molding Characteristics

Crystal Polystyrene offers excellent clarity and rigidity but is more brittle, requiring precise temperature control during processing to prevent defects and warping. HIPS (High Impact Polystyrene) contains rubber modifiers, enhancing its impact resistance and flexibility, allowing for easier molding with less risk of cracking or stress-related failures. Both materials are compatible with standard injection molding techniques, though HIPS typically allows faster cycle times due to better flow properties and higher impact tolerance.

Cost Comparison and Market Availability

Crystal Polystyrene generally has a lower cost compared to High Impact Polystyrene (HIPS) due to its simpler manufacturing process and fewer additives, making it an economical choice for clear, rigid applications. HIPS, while more expensive, offers enhanced impact resistance and durability, driving its demand in industries requiring tougher materials such as automotive and packaging. Market availability favors HIPS because of its widespread use in protective and structural components, whereas Crystal Polystyrene is more niche, primarily found in consumer goods and display products.

Environmental Considerations and Recycling

Crystal polystyrene (PS) is a clear, rigid plastic primarily used in packaging, and although recyclable, it often faces contamination challenges that reduce recycling efficiency compared to High Impact Polystyrene (HIPS), which contains rubber additives improving durability but complicating recycling processes. HIPS recycling requires specialized facilities to handle its composite structure, leading to fewer recycling options and increased environmental impact due to longer degradation times in landfills. Both materials contribute to plastic pollution if not properly recycled, highlighting the need for enhanced collection systems and advanced recycling technologies focused on polystyrene waste management.

Typical Industry Standards and Specifications

Crystal Polystyrene (PS) is characterized by its high clarity, low impact resistance, and usage in applications requiring transparency, meeting standards such as ASTM D856 for clarity and ASTM D638 for tensile properties. High Impact Polystyrene (HIPS) offers enhanced toughness and impact resistance due to rubber modification, conforming to ASTM D256 for impact strength and ASTM D790 for flexural modulus, making it suitable for more demanding mechanical applications. Typical industry specifications differentiate Crystal PS with greater surface gloss and transparency, while HIPS is favored for durability and dimensional stability in automotive, packaging, and appliance components.

Choosing Between Crystal Polystyrene and HIPS

Crystal Polystyrene offers superior clarity and rigidity, making it ideal for applications requiring transparent and aesthetically pleasing packaging. HIPS (High Impact Polystyrene) provides enhanced impact resistance and toughness, suitable for products that demand durability and strength, such as appliance housings and automotive parts. Selecting between Crystal Polystyrene and HIPS depends on prioritizing optical clarity or mechanical toughness based on specific end-use requirements.

Crystal Polystyrene vs HIPS (High Impact Polystyrene) Infographic

materialdif.com

materialdif.com