Polystyrene beads are lightweight, rigid, and offer excellent insulation properties, making them ideal for packaging and insulation applications. Polyethylene beads, on the other hand, are more flexible, impact-resistant, and commonly used in products requiring cushioning, such as bean bags and soft toys. While polystyrene beads provide better structural support, polyethylene beads are preferred for comfort and durability in flexible applications.

Table of Comparison

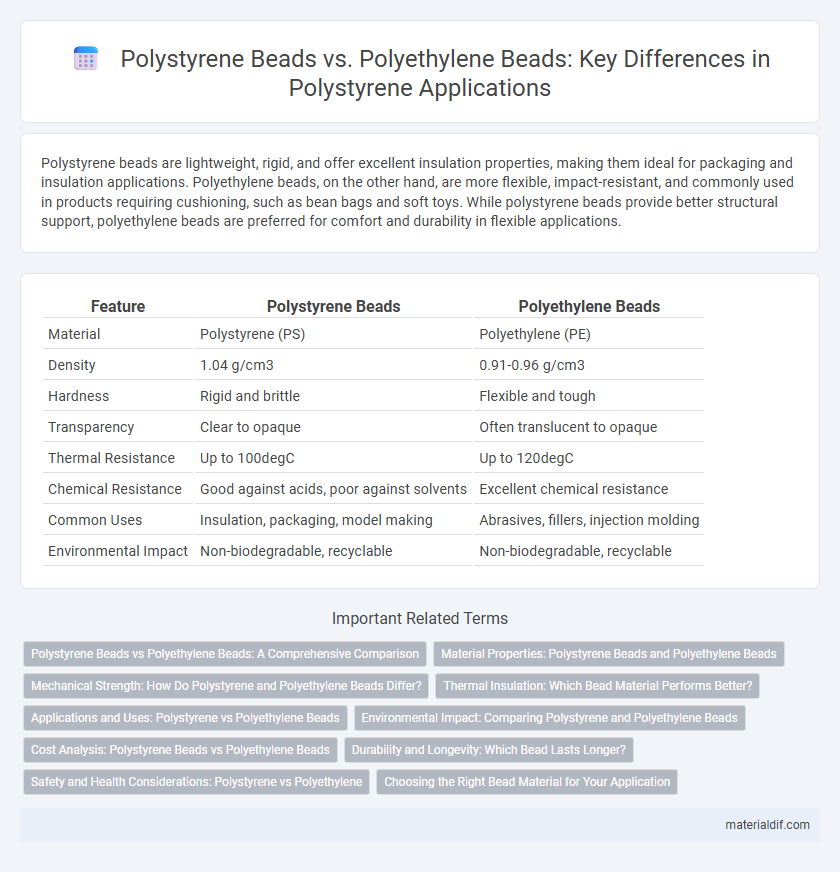

| Feature | Polystyrene Beads | Polyethylene Beads |

|---|---|---|

| Material | Polystyrene (PS) | Polyethylene (PE) |

| Density | 1.04 g/cm3 | 0.91-0.96 g/cm3 |

| Hardness | Rigid and brittle | Flexible and tough |

| Transparency | Clear to opaque | Often translucent to opaque |

| Thermal Resistance | Up to 100degC | Up to 120degC |

| Chemical Resistance | Good against acids, poor against solvents | Excellent chemical resistance |

| Common Uses | Insulation, packaging, model making | Abrasives, fillers, injection molding |

| Environmental Impact | Non-biodegradable, recyclable | Non-biodegradable, recyclable |

Polystyrene Beads vs Polyethylene Beads: A Comprehensive Comparison

Polystyrene beads exhibit higher rigidity and thermal stability compared to polyethylene beads, making them ideal for applications requiring structural integrity and heat resistance. Polyethylene beads demonstrate superior flexibility and impact resistance, useful in cushioning and packaging products. The choice between polystyrene and polyethylene beads depends on specific requirements such as mechanical strength, chemical resistance, and environmental exposure conditions.

Material Properties: Polystyrene Beads and Polyethylene Beads

Polystyrene beads exhibit higher rigidity and thermal resistance compared to polyethylene beads, making them suitable for applications requiring structural stability and heat tolerance. Polyethylene beads offer superior flexibility, chemical resistance, and impact absorption, which are beneficial for cushioning and packaging uses. The density difference, with polystyrene beads being lighter, also influences their selection based on application-specific weight and durability requirements.

Mechanical Strength: How Do Polystyrene and Polyethylene Beads Differ?

Polystyrene beads exhibit higher mechanical strength and rigidity compared to polyethylene beads, making them better suited for applications requiring structural durability. Polyethylene beads offer greater flexibility and impact resistance but generally have lower tensile strength than polystyrene. The molecular structure of polystyrene, featuring a rigid aromatic ring, contributes to its superior stiffness, whereas polyethylene's long, flexible polymer chains allow for enhanced elasticity.

Thermal Insulation: Which Bead Material Performs Better?

Polystyrene beads offer superior thermal insulation due to their closed-cell structure, which traps air and reduces heat transfer more effectively than polyethylene beads. Polyethylene beads, while lightweight and flexible, have a more open-cell structure that allows greater thermal conductivity and lower insulating properties. Thus, polystyrene beads are preferred in applications requiring enhanced energy efficiency and temperature regulation.

Applications and Uses: Polystyrene vs Polyethylene Beads

Polystyrene beads are widely used in insulation, packaging, and as a lightweight filler due to their rigidity and thermal resistance, making them ideal for applications requiring structural stability and heat retention. Polyethylene beads, characterized by their flexibility and chemical resistance, find applications in soft cushioning, anti-static materials, and drug delivery systems. The choice between polystyrene and polyethylene beads depends on the specific requirements of durability, chemical inertness, and mechanical properties in industries such as construction, pharmaceuticals, and consumer goods.

Environmental Impact: Comparing Polystyrene and Polyethylene Beads

Polystyrene beads decompose slowly and release toxic styrene monomers, causing significant environmental hazards, especially in marine ecosystems where they contribute to microplastic pollution. Polyethylene beads, while also persistent pollutants, generally exhibit lower toxicity and break down into less harmful byproducts over time. Both materials pose challenges for waste management, but polyethylene beads tend to have a comparatively reduced environmental impact due to their chemical stability and non-toxic degradation pathways.

Cost Analysis: Polystyrene Beads vs Polyethylene Beads

Polystyrene beads generally offer a lower production cost compared to polyethylene beads due to simpler polymerization and raw material expenses. While polystyrene beads are more cost-effective for applications requiring rigidity and clarity, polyethylene beads tend to be pricier but provide superior flexibility and chemical resistance. Cost analysis must also factor in the intended use, as polyethylene's durability may reduce lifecycle expenses despite higher initial investment.

Durability and Longevity: Which Bead Lasts Longer?

Polystyrene beads offer moderate durability with resistance to moisture and impact but tend to degrade faster under prolonged UV exposure compared to polyethylene beads. Polyethylene beads exhibit superior longevity due to their high chemical resistance and ability to withstand harsh environmental conditions without significant degradation. For applications demanding extended lifespan and durability, polyethylene beads are generally the preferred choice over polystyrene beads.

Safety and Health Considerations: Polystyrene vs Polyethylene

Polystyrene beads pose higher health risks due to potential styrene monomer leaching, which is classified as a possible carcinogen by the International Agency for Research on Cancer (IARC). Polyethylene beads, being chemically inert and non-toxic, offer safer handling and reduced environmental impact in consumer applications. Both materials require proper ventilation during manufacturing to minimize inhalation hazards, but polyethylene's biocompatibility makes it preferable in medical and food-related products.

Choosing the Right Bead Material for Your Application

Polystyrene beads offer excellent rigidity, clarity, and thermal insulation, making them ideal for applications requiring lightweight packaging or cushioning in electronics. Polyethylene beads provide superior flexibility, chemical resistance, and durability, preferred in products needing impact absorption or moisture resistance such as insulation and floats. Selecting the right bead material depends on factors like mechanical strength, environmental exposure, and cost-effectiveness tailored to specific application needs.

Polystyrene Beads vs Polyethylene Beads Infographic

materialdif.com

materialdif.com