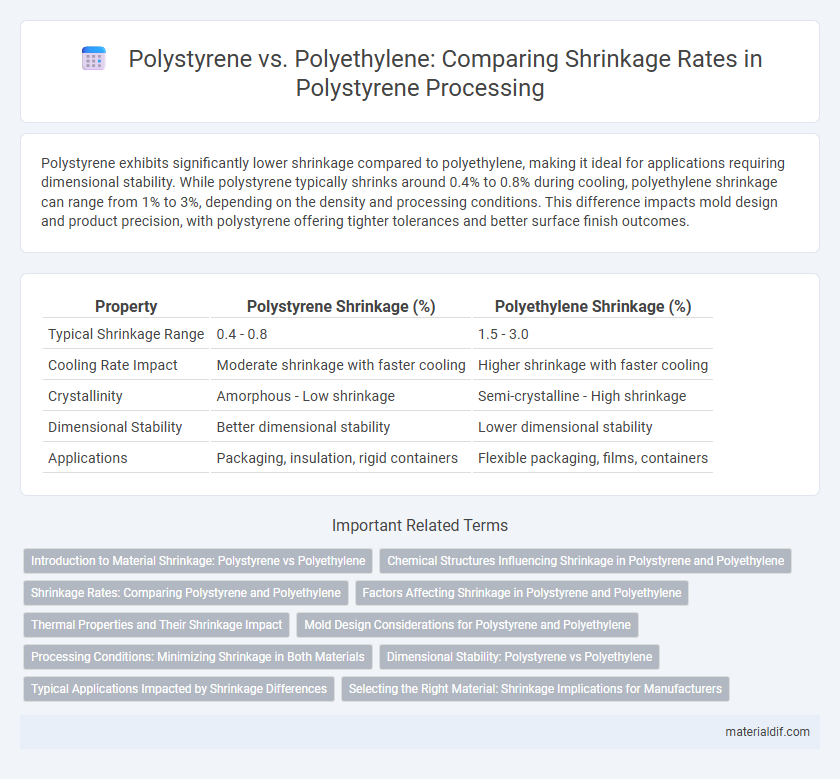

Polystyrene exhibits significantly lower shrinkage compared to polyethylene, making it ideal for applications requiring dimensional stability. While polystyrene typically shrinks around 0.4% to 0.8% during cooling, polyethylene shrinkage can range from 1% to 3%, depending on the density and processing conditions. This difference impacts mold design and product precision, with polystyrene offering tighter tolerances and better surface finish outcomes.

Table of Comparison

| Property | Polystyrene Shrinkage (%) | Polyethylene Shrinkage (%) |

|---|---|---|

| Typical Shrinkage Range | 0.4 - 0.8 | 1.5 - 3.0 |

| Cooling Rate Impact | Moderate shrinkage with faster cooling | Higher shrinkage with faster cooling |

| Crystallinity | Amorphous - Low shrinkage | Semi-crystalline - High shrinkage |

| Dimensional Stability | Better dimensional stability | Lower dimensional stability |

| Applications | Packaging, insulation, rigid containers | Flexible packaging, films, containers |

Introduction to Material Shrinkage: Polystyrene vs Polyethylene

Polystyrene exhibits higher shrinkage rates compared to polyethylene due to its rigid molecular structure and lower elongation capacity. Polyethylene's flexible polymer chains allow it to undergo less dimensional change during cooling, resulting in lower shrinkage values, typically ranging from 1% to 3%. Understanding these differences is critical for applications requiring precise dimensional tolerances and stability in plastic molded parts.

Chemical Structures Influencing Shrinkage in Polystyrene and Polyethylene

Polystyrene exhibits lower shrinkage compared to polyethylene due to its rigid aromatic phenyl side groups, which restrict molecular chain mobility and reduce dimensional changes during cooling. In contrast, polyethylene's flexible aliphatic chains allow greater segmental motion, leading to higher shrinkage as the material solidifies. The presence of the benzene ring in polystyrene's chemical structure significantly enhances dimensional stability, while polyethylene's simpler hydrocarbon backbone contributes to its increased shrinkage.

Shrinkage Rates: Comparing Polystyrene and Polyethylene

Polystyrene exhibits significantly lower shrinkage rates compared to polyethylene, typically ranging from 0.5% to 2%, whereas polyethylene shrinkage rates can vary between 2% and 7% depending on the molecular weight and processing conditions. The lower shrinkage rate of polystyrene contributes to better dimensional stability and precision in molded products, making it ideal for applications requiring tight tolerances. Polyethylene's higher shrinkage rate, influenced by its amorphous and semi-crystalline structure, suits applications where flexibility and impact resistance are prioritized over dimensional exactness.

Factors Affecting Shrinkage in Polystyrene and Polyethylene

Polystyrene shrinkage is primarily influenced by its crystalline structure and cooling rate, resulting in lower dimensional changes compared to polyethylene, which exhibits higher shrinkage due to its semi-crystalline nature and greater chain mobility. Factors affecting polystyrene shrinkage include mold temperature, injection pressure, and cooling time, which control its molecular orientation and residual stress. Conversely, polyethylene shrinkage is strongly affected by molecular weight distribution, crystallinity, and cooling conditions, leading to greater variability and higher overall shrinkage rates.

Thermal Properties and Their Shrinkage Impact

Polystyrene exhibits lower thermal expansion and shrinkage rates compared to polyethylene due to its rigid aromatic polymer backbone, which provides greater dimensional stability under heat. Polyethylene's semicrystalline structure leads to higher thermal expansion and more pronounced shrinkage when exposed to elevated temperatures, impacting its suitability for applications requiring tight dimensional tolerances. Thermal properties such as glass transition temperature (Tg) and melting point significantly influence shrinkage behavior, with polystyrene's higher Tg (~100degC) resulting in reduced deformation compared to polyethylene's lower Tg (below -100degC) and melting points around 115-135degC.

Mold Design Considerations for Polystyrene and Polyethylene

Polystyrene exhibits significantly lower shrinkage rates, typically around 0.4-0.7%, compared to polyethylene's higher shrinkage of 1.5-3%, necessitating tighter dimensional control in mold design for polystyrene parts. Mold designers must account for polystyrene's minimal shrinkage by ensuring precise cavity dimensions and incorporating adequate venting to prevent defects such as sink marks and warpage. In contrast, polyethylene molds require allowance for greater shrinkage with larger draft angles and flexible gating systems to accommodate its higher molecular mobility and crystallinity variations.

Processing Conditions: Minimizing Shrinkage in Both Materials

Polystyrene exhibits lower shrinkage rates compared to polyethylene due to its rigid aromatic backbone, which limits molecular mobility during cooling. Processing conditions such as mold temperature and cooling rate must be carefully controlled for polystyrene to minimize internal stresses and deformation. In polyethylene, higher shrinkage can be mitigated by optimizing cooling profiles and maintaining consistent melt temperatures to ensure uniform crystallinity and dimensional stability.

Dimensional Stability: Polystyrene vs Polyethylene

Polystyrene exhibits lower shrinkage rates compared to polyethylene, resulting in superior dimensional stability in applications requiring precise tolerances. Its rigid molecular structure minimizes deformation under thermal stress, whereas polyethylene's semi-crystalline nature promotes higher shrinkage due to greater molecular mobility. Consequently, polystyrene is preferred in products where maintaining shape and size consistency is critical.

Typical Applications Impacted by Shrinkage Differences

Polystyrene exhibits lower shrinkage rates compared to polyethylene, making it ideal for applications requiring precise dimensional stability such as packaging materials for electronics and medical devices. Polyethylene's higher shrinkage is advantageous in stretch films and shrink wraps used for pallet stabilization and flexible packaging. Understanding these shrinkage properties guides material selection to optimize performance in packaging, insulation, and consumer goods industries.

Selecting the Right Material: Shrinkage Implications for Manufacturers

Polystyrene exhibits low shrinkage rates, typically around 0.4-0.6%, making it ideal for applications requiring dimensional stability and precise molding. In contrast, polyethylene shrinkage ranges from 1.5% to 3%, which can lead to greater dimensional variation and potential warping during cooling. Manufacturers must consider these shrinkage characteristics to select the appropriate polymer, ensuring product accuracy, structural integrity, and optimal processing conditions.

Polystyrene shrinkage vs Polyethylene shrinkage Infographic

materialdif.com

materialdif.com