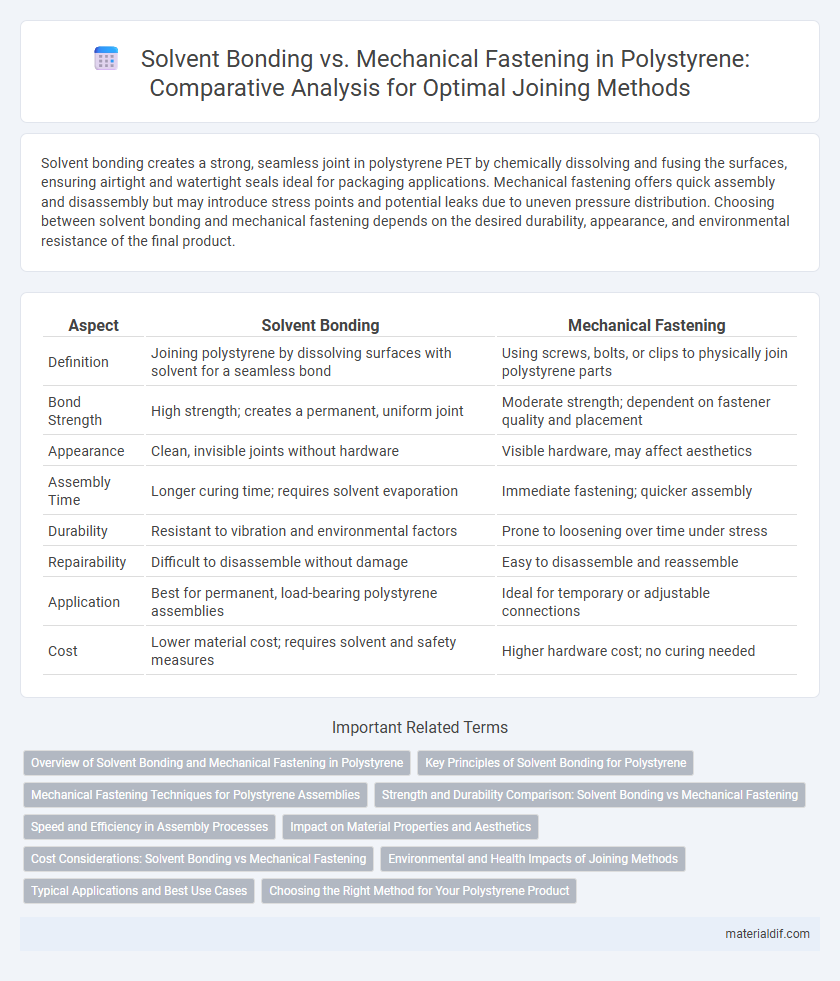

Solvent bonding creates a strong, seamless joint in polystyrene PET by chemically dissolving and fusing the surfaces, ensuring airtight and watertight seals ideal for packaging applications. Mechanical fastening offers quick assembly and disassembly but may introduce stress points and potential leaks due to uneven pressure distribution. Choosing between solvent bonding and mechanical fastening depends on the desired durability, appearance, and environmental resistance of the final product.

Table of Comparison

| Aspect | Solvent Bonding | Mechanical Fastening |

|---|---|---|

| Definition | Joining polystyrene by dissolving surfaces with solvent for a seamless bond | Using screws, bolts, or clips to physically join polystyrene parts |

| Bond Strength | High strength; creates a permanent, uniform joint | Moderate strength; dependent on fastener quality and placement |

| Appearance | Clean, invisible joints without hardware | Visible hardware, may affect aesthetics |

| Assembly Time | Longer curing time; requires solvent evaporation | Immediate fastening; quicker assembly |

| Durability | Resistant to vibration and environmental factors | Prone to loosening over time under stress |

| Repairability | Difficult to disassemble without damage | Easy to disassemble and reassemble |

| Application | Best for permanent, load-bearing polystyrene assemblies | Ideal for temporary or adjustable connections |

| Cost | Lower material cost; requires solvent and safety measures | Higher hardware cost; no curing needed |

Overview of Solvent Bonding and Mechanical Fastening in Polystyrene

Solvent bonding in polystyrene creates a strong molecular connection by softening the polymer surface with solvents like acetone or toluene, allowing polymer chains to fuse upon evaporation. Mechanical fastening uses physical methods such as screws, rivets, or clips to join polystyrene parts, providing immediate hold but potentially causing stress points or damage. Solvent bonding results in a seamless, aesthetically clean joint suited for load-bearing applications, while mechanical fastening offers ease of disassembly and repositioning.

Key Principles of Solvent Bonding for Polystyrene

Solvent bonding for polystyrene relies on dissolving the polymer surface with a solvent such as acetone or methyl ethyl ketone to create a weld-like joint upon evaporation. This process ensures strong molecular interdiffusion between the joined parts without introducing additional materials or mechanical stress. Achieving optimal bond strength requires precise control of solvent application, joint design, and curing time to prevent surface crazing and ensure durable adhesion.

Mechanical Fastening Techniques for Polystyrene Assemblies

Mechanical fastening techniques for polystyrene assemblies include screws, rivets, and snap-fits, providing strong, durable joints without chemical exposure. These methods preserve the integrity of polystyrene by avoiding solvent interaction, which can cause stress or deformation. Mechanical fasteners are ideal for applications requiring disassembly or reinforcement, ensuring precise alignment and robust structural support.

Strength and Durability Comparison: Solvent Bonding vs Mechanical Fastening

Solvent bonding creates a strong, homogeneous joint in polystyrene by chemically fusing surfaces, resulting in superior tensile strength and long-term durability compared to mechanical fastening. Mechanical fastening, such as screws or rivets, introduces stress concentration points that may weaken polystyrene over time, leading to potential cracking or loosening under repeated load or environmental exposure. Studies show solvent-bonded polystyrene joints maintain integrity better in dynamic applications, making them preferable for structural or load-bearing assemblies.

Speed and Efficiency in Assembly Processes

Solvent bonding of polystyrene creates strong, seamless joints rapidly by chemically fusing surfaces, significantly reducing assembly time compared to mechanical fastening. Mechanical fastening methods like screws or clips require more labor and time due to precise alignment and tightening processes. The efficiency gains from solvent bonding make it the preferred choice in high-volume polystyrene product manufacturing where speed and reliability are critical.

Impact on Material Properties and Aesthetics

Solvent bonding polystyrene creates a seamless joint by chemically fusing surfaces, preserving material clarity and uniformity but potentially altering molecular structure and mechanical strength at the bond area. Mechanical fastening, such as screws or rivets, maintains the intrinsic properties of polystyrene but introduces stress concentration points and visible hardware, which may compromise aesthetics and durability. Balancing impact resistance and visual appeal depends on the application's tolerance for surface integrity versus joint strength.

Cost Considerations: Solvent Bonding vs Mechanical Fastening

Solvent bonding of polystyrene typically incurs lower initial material and labor costs compared to mechanical fastening, as it eliminates the need for screws, bolts, or additional hardware. Mechanical fastening can increase expenses due to the requirement for precise drilling, fasteners, and potential rework caused by material stress or damage. Over the product lifecycle, solvent bonding offers improved sealing and structural integrity, potentially reducing maintenance costs compared to mechanical fastening assemblies in polystyrene applications.

Environmental and Health Impacts of Joining Methods

Solvent bonding of polystyrene involves the use of chemical solvents that can release volatile organic compounds (VOCs), posing inhalation risks and contributing to indoor air pollution. Mechanical fastening avoids chemical exposure but may generate microplastics through wear and tear, impacting environmental ecosystems. Selecting joining methods requires balancing solvent toxicity concerns with potential plastic debris from fasteners to minimize overall environmental and health impacts.

Typical Applications and Best Use Cases

Solvent bonding of polystyrene is ideal for creating seamless, strong joints in laboratory equipment, medical devices, and display cases where clear, airtight seals are critical. Mechanical fastening suits applications requiring disassembly or adjustment, such as prototypes, enclosures, and temporary assemblies, by providing flexibility without compromising material integrity. Choosing solvent bonding offers enhanced chemical resistance and aesthetic quality, while mechanical fastening supports maintenance and modular designs in polystyrene products.

Choosing the Right Method for Your Polystyrene Product

Selecting the optimal joining technique for polystyrene hinges on the product's intended use, load requirements, and environmental exposure. Solvent bonding offers a seamless, strong bond ideal for smooth surfaces and applications demanding aesthetic appeal and chemical resistance, while mechanical fastening provides flexibility for disassembly and is suitable for prototypes or temporary assemblies. Evaluating factors such as stress distribution, exposure to solvents or heat, and assembly speed ensures the choice aligns with performance and durability standards.

Solvent Bonding vs Mechanical Fastening Infographic

materialdif.com

materialdif.com