EPS molding uses expanded polystyrene beads heated and molded into lightweight, impact-resistant shapes ideal for packaging, while injection molding melts polystyrene pellets and injects them into precise, high-detail molds suitable for durable, complex parts. EPS molding excels in producing large, insulating foam products with minimal material waste, whereas injection molding allows for faster production cycles and intricate design customization with higher surface finish quality. Understanding these differences helps optimize manufacturing techniques based on product requirements, cost constraints, and performance characteristics.

Table of Comparison

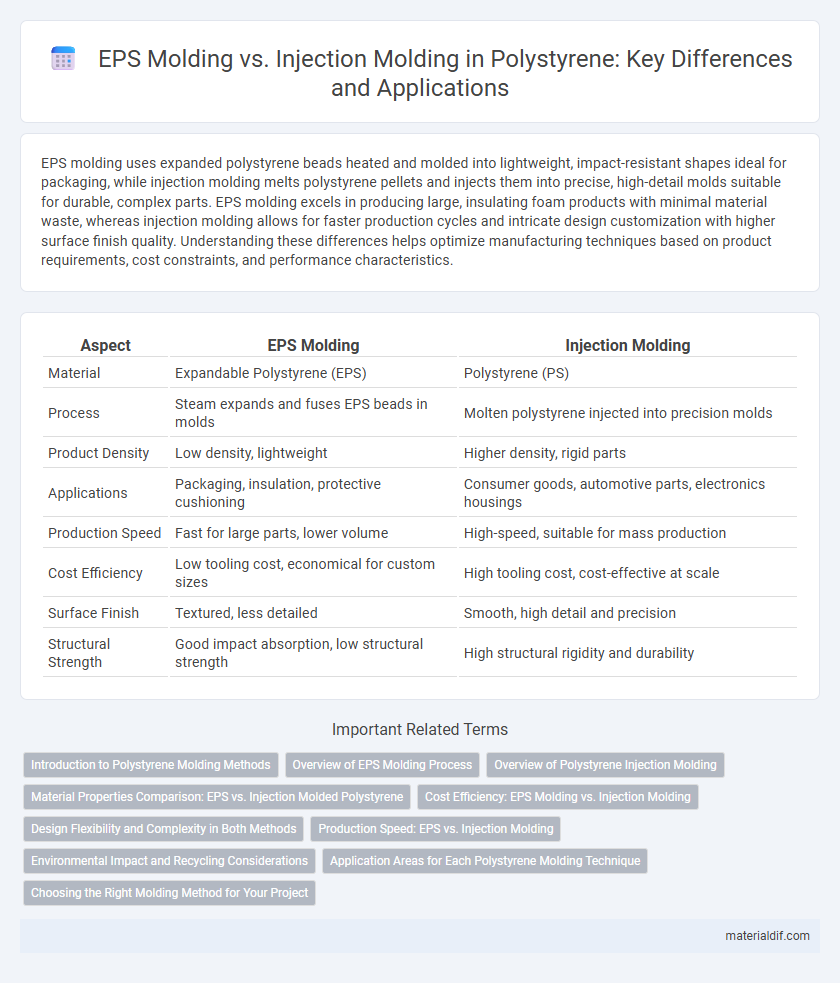

| Aspect | EPS Molding | Injection Molding |

|---|---|---|

| Material | Expandable Polystyrene (EPS) | Polystyrene (PS) |

| Process | Steam expands and fuses EPS beads in molds | Molten polystyrene injected into precision molds |

| Product Density | Low density, lightweight | Higher density, rigid parts |

| Applications | Packaging, insulation, protective cushioning | Consumer goods, automotive parts, electronics housings |

| Production Speed | Fast for large parts, lower volume | High-speed, suitable for mass production |

| Cost Efficiency | Low tooling cost, economical for custom sizes | High tooling cost, cost-effective at scale |

| Surface Finish | Textured, less detailed | Smooth, high detail and precision |

| Structural Strength | Good impact absorption, low structural strength | High structural rigidity and durability |

Introduction to Polystyrene Molding Methods

Expanded Polystyrene (EPS) molding utilizes steam to expand beads into lightweight, rigid foam shapes ideal for insulation and packaging, emphasizing low-density and impact absorption properties. Injection molding involves melting polystyrene pellets and injecting the molten polymer into precise metal molds, producing high-strength, detailed parts used in automotive, consumer goods, and electronics. Both methods leverage polystyrene's versatility, with EPS molding focused on foam applications and injection molding delivering durable, complex components.

Overview of EPS Molding Process

Expanded Polystyrene (EPS) molding involves a steam-chilling process where pre-expanded beads are placed into molds and heated with steam, causing them to fuse and conform to the mold shape. This method allows for lightweight, impact-resistant, and insulating foam products with minimal waste. EPS molding is ideal for packaging, insulation panels, and custom-shaped cushioning, differing from injection molding by its ability to create larger, low-density parts cost-effectively.

Overview of Polystyrene Injection Molding

Polystyrene injection molding involves melting polystyrene pellets and injecting the molten polymer into precision-engineered molds, enabling complex and detailed part production with high dimensional accuracy. Compared to EPS molding, injection molding offers superior surface finish, faster cycle times, and stronger, denser parts suited for durable consumer goods and electronics housings. This process enables mass production of uniform components, leveraging the thermoplastic nature of polystyrene for recyclability and customizable properties through additives.

Material Properties Comparison: EPS vs. Injection Molded Polystyrene

Expanded Polystyrene (EPS) exhibits lower density and superior thermal insulation properties compared to injection molded polystyrene, making it ideal for lightweight packaging and insulation applications. Injection molded polystyrene offers higher mechanical strength, dimensional stability, and surface finish quality, suitable for precision components and consumer products. The cellular structure of EPS results in impact resistance and cushioning benefits, whereas injection molded polystyrene's homogenous density enhances rigidity and durability.

Cost Efficiency: EPS Molding vs. Injection Molding

EPS molding offers superior cost efficiency for large, lightweight, and low-complexity polystyrene products due to lower tooling expenses and faster cycle times. Injection molding incurs higher initial costs from complex molds and longer setup, making it more suitable for high-precision, smaller volume parts. For industries prioritizing cost-effective mass production of bulky EPS components, EPS molding remains the economically advantageous choice.

Design Flexibility and Complexity in Both Methods

EPS molding offers greater design flexibility for lightweight, complex shapes with intricate internal structures, ideal for custom packaging and insulation applications. Injection molding allows for high precision and detailed surface finishes, supporting complex geometries but is better suited for smaller, dense parts due to material flow constraints. Both methods enable tailored polystyrene components, but injection molding excels in detailed, durable parts while EPS molding is optimal for larger, lightweight designs.

Production Speed: EPS vs. Injection Molding

Expanded Polystyrene (EPS) molding offers faster production speed compared to injection molding due to its lightweight material and simplified foam expansion process. Injection molding of polystyrene requires longer cycle times for melting, cooling, and solidifying the plastic within molds, resulting in slower throughput. High-volume manufacturing favors EPS for rapid prototyping and packaging applications where speed is critical.

Environmental Impact and Recycling Considerations

EPS molding produces lightweight, low-density products that are highly recyclable and often reused in insulation and packaging, significantly reducing landfill waste. Injection molding creates dense, durable polystyrene items but can lead to greater material waste and energy consumption during production. Recycling EPS from molding applications faces challenges due to contamination and collection inefficiencies, whereas injection-molded polystyrene often requires specialized recycling streams to manage environmental impact effectively.

Application Areas for Each Polystyrene Molding Technique

EPS molding excels in packaging, insulation panels, and lightweight construction materials due to its thermal insulation properties and cushioning capabilities. Injection molding of polystyrene is preferred for producing high-precision components in automotive parts, consumer electronics, and medical devices where detailed shapes and tight tolerances are critical. Each molding technique targets distinct application areas, with EPS molding favored for large, energy-efficient products and injection molding dominating complex, durable, and detailed plastic parts.

Choosing the Right Molding Method for Your Project

Selecting between EPS molding and injection molding depends on project requirements such as complexity, production volume, and material properties. EPS molding excels in creating lightweight, insulating, and cost-effective foam products ideal for packaging and thermal insulation, while injection molding delivers high precision and durability for complex polystyrene parts used in automotive or consumer goods. Evaluating factors like design intricacy, surface finish, cycle time, and budget ensures the optimal choice of molding technique for efficient manufacturing and product performance.

EPS molding vs Injection molding Infographic

materialdif.com

materialdif.com