Polystyrene resin is a rigid, transparent polymer primarily used in packaging and insulation, known for its brittleness and ease of molding. Polystyrene copolymer, modified with other monomers like acrylonitrile or butadiene, offers enhanced impact resistance and flexibility, making it suitable for automotive parts and consumer goods. The choice between polystyrene resin and copolymer depends on the required mechanical properties and application demands.

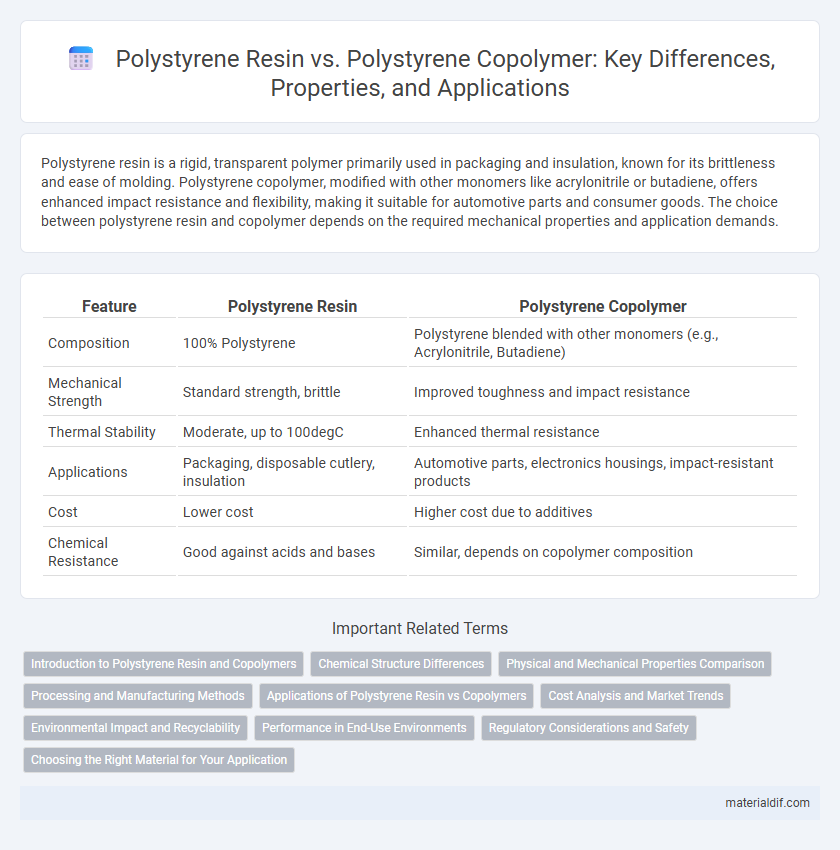

Table of Comparison

| Feature | Polystyrene Resin | Polystyrene Copolymer |

|---|---|---|

| Composition | 100% Polystyrene | Polystyrene blended with other monomers (e.g., Acrylonitrile, Butadiene) |

| Mechanical Strength | Standard strength, brittle | Improved toughness and impact resistance |

| Thermal Stability | Moderate, up to 100degC | Enhanced thermal resistance |

| Applications | Packaging, disposable cutlery, insulation | Automotive parts, electronics housings, impact-resistant products |

| Cost | Lower cost | Higher cost due to additives |

| Chemical Resistance | Good against acids and bases | Similar, depends on copolymer composition |

Introduction to Polystyrene Resin and Copolymers

Polystyrene resin is a synthetic aromatic hydrocarbon polymer derived from the monomer styrene, widely used for its rigidity, clarity, and ease of processing in packaging, insulation, and disposable containers. Polystyrene copolymers, such as ABS (Acrylonitrile Butadiene Styrene) and SAN (Styrene Acrylonitrile), combine styrene with other monomers to enhance impact resistance, mechanical strength, and chemical resistance. These copolymers offer tailored physical properties, making them suitable for automotive parts, electronics housings, and consumer goods where durability and performance are critical.

Chemical Structure Differences

Polystyrene resin consists of repeating styrene monomer units forming a homopolymer with a rigid, aromatic backbone that provides clarity and brittleness. In contrast, polystyrene copolymers incorporate additional monomers like acrylonitrile or butadiene into the polymer chain, altering the chemical structure to enhance toughness, impact resistance, or heat resistance. The incorporation of different monomer units in copolymers disrupts the regularity of the polystyrene chain, resulting in varied physical properties tailored for specific applications.

Physical and Mechanical Properties Comparison

Polystyrene resin exhibits high rigidity and excellent dimensional stability, making it ideal for applications requiring strength and clarity. Polystyrene copolymer, often combined with rubber or other monomers, shows improved impact resistance and toughness while maintaining good mechanical strength. The copolymer's enhanced flexibility and higher elongation at break distinguish it from the more brittle homopolymer resin, allowing for broader usage in impact-resistant products.

Processing and Manufacturing Methods

Polystyrene resin is typically processed through injection molding, extrusion, and thermoforming due to its rigidity and ease of melting, making it ideal for producing clear, rigid products. Polystyrene copolymers, such as styrene-butadiene or acrylonitrile-styrene-butadiene, require more controlled processing techniques like reaction injection molding and extrusion with precise temperature regulation to accommodate their enhanced flexibility and impact resistance. Manufacturing methods for copolymers often involve complex polymerization processes, including emulsion and suspension polymerization, which differ from the bulk polymerization commonly used for pure polystyrene resin.

Applications of Polystyrene Resin vs Copolymers

Polystyrene resin is widely used in manufacturing rigid packaging, disposable cutlery, and insulation materials due to its clarity and ease of molding. Polystyrene copolymers, such as acrylonitrile-butadiene-styrene (ABS) and styrene-acrylonitrile (SAN), offer enhanced impact resistance and durability, making them suitable for automotive parts, electronic housings, and appliances. The distinct mechanical properties of polystyrene copolymers expand their application in industries requiring toughness and chemical resistance compared to pure polystyrene resin.

Cost Analysis and Market Trends

Polystyrene resin typically offers lower production costs due to its simpler polymer structure, making it cost-effective for applications such as packaging and disposable cutlery. Polystyrene copolymers, including ABS and HIPS, command higher prices as they provide enhanced mechanical properties and thermal resistance, catering to automotive and electronics markets. Market trends indicate growing demand for polystyrene copolymers driven by increasing automotive lightweighting and consumer electronics, while significant volume growth remains anchored in standard polystyrene resin for cost-sensitive packaging sectors.

Environmental Impact and Recyclability

Polystyrene resin, primarily composed of styrene monomers, exhibits lower recyclability due to its rigid thermoplastic nature and limited biodegradability, often contributing to persistent environmental pollution in landfills and marine ecosystems. Polystyrene copolymers incorporate comonomers like acrylonitrile or butadiene, enhancing mechanical properties and sometimes improving recycling potential through better compatibility with recycling streams. Despite the copolymer's improved performance, both materials pose environmental challenges due to their resistance to biodegradation, necessitating advanced recycling technologies and robust waste management strategies to mitigate ecological impact.

Performance in End-Use Environments

Polystyrene resin offers high rigidity and clarity, making it ideal for applications requiring transparency and easy moldability, such as packaging and disposable cutlery. Polystyrene copolymer, incorporating rubber or other monomers, enhances impact resistance and toughness, improving durability in environments subject to mechanical stress or fluctuating temperatures. Performance in end-use environments varies significantly; resin excels in lightweight, aesthetic applications while copolymers perform better in automotive parts, appliances, and protective equipment due to their superior impact strength and resilience.

Regulatory Considerations and Safety

Polystyrene resin is regulated under FDA 21 CFR 177.1640 for food contact applications, emphasizing purity and residual monomer limits to ensure consumer safety. Polystyrene copolymers, incorporating monomers like acrylonitrile or butadiene, face broader regulatory scrutiny due to potential variations in chemical composition and migration profiles, requiring compliance with additional standards such as REACH and TSCA. Safety evaluations for both materials prioritize low residual styrene content and absence of toxic additives to minimize health risks in food packaging and consumer products.

Choosing the Right Material for Your Application

Polystyrene resin offers high rigidity and clarity, making it ideal for applications requiring transparency and dimensional stability, such as packaging and disposable cutlery. Polystyrene copolymer incorporates other monomers like acrylonitrile or butadiene, enhancing impact resistance and thermal stability, suited for automotive parts and durable consumer goods. Selecting between polystyrene resin and copolymer depends on the specific performance needs of the application, including toughness, flexibility, and environmental exposure.

Polystyrene Resin vs Polystyrene Copolymer Infographic

materialdif.com

materialdif.com