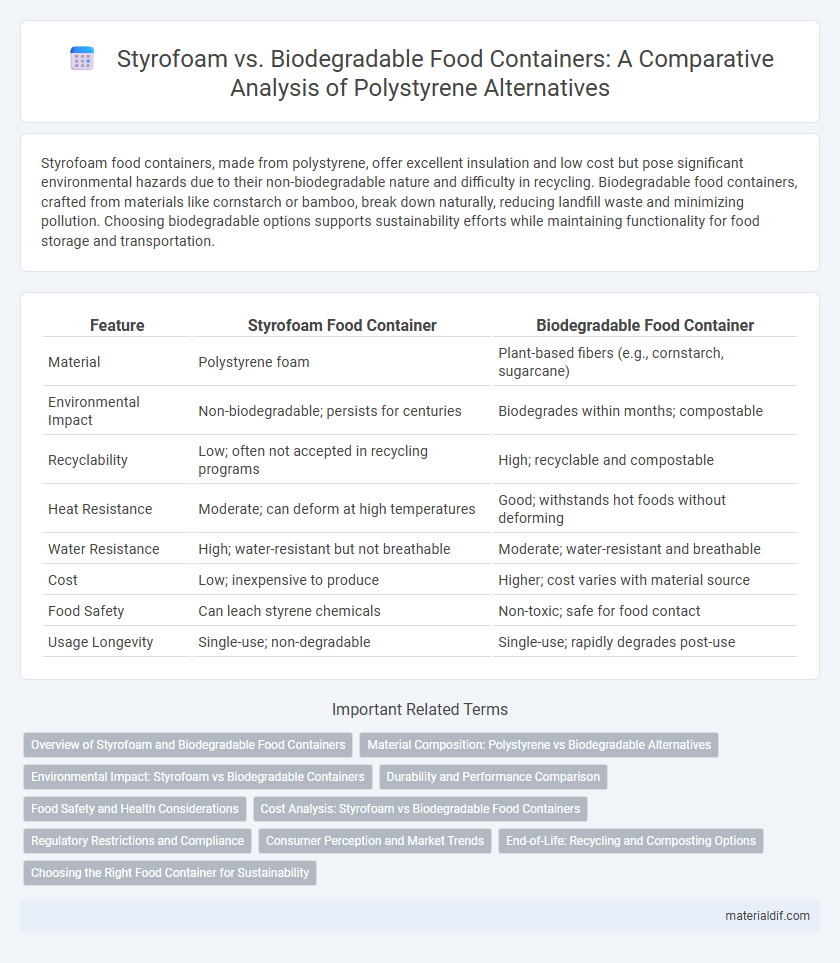

Styrofoam food containers, made from polystyrene, offer excellent insulation and low cost but pose significant environmental hazards due to their non-biodegradable nature and difficulty in recycling. Biodegradable food containers, crafted from materials like cornstarch or bamboo, break down naturally, reducing landfill waste and minimizing pollution. Choosing biodegradable options supports sustainability efforts while maintaining functionality for food storage and transportation.

Table of Comparison

| Feature | Styrofoam Food Container | Biodegradable Food Container |

|---|---|---|

| Material | Polystyrene foam | Plant-based fibers (e.g., cornstarch, sugarcane) |

| Environmental Impact | Non-biodegradable; persists for centuries | Biodegrades within months; compostable |

| Recyclability | Low; often not accepted in recycling programs | High; recyclable and compostable |

| Heat Resistance | Moderate; can deform at high temperatures | Good; withstands hot foods without deforming |

| Water Resistance | High; water-resistant but not breathable | Moderate; water-resistant and breathable |

| Cost | Low; inexpensive to produce | Higher; cost varies with material source |

| Food Safety | Can leach styrene chemicals | Non-toxic; safe for food contact |

| Usage Longevity | Single-use; non-degradable | Single-use; rapidly degrades post-use |

Overview of Styrofoam and Biodegradable Food Containers

Styrofoam food containers, made from expanded polystyrene foam, offer lightweight insulation and low cost but pose significant environmental challenges due to their non-biodegradable nature and long decomposition time. Biodegradable food containers, often crafted from materials like cornstarch, sugarcane bagasse, or bamboo fibers, provide eco-friendly alternatives that break down naturally within months under proper composting conditions. Choosing biodegradable containers reduces plastic pollution and supports sustainable waste management in the food industry.

Material Composition: Polystyrene vs Biodegradable Alternatives

Styrofoam food containers are primarily made from expanded polystyrene (EPS), a petroleum-based plastic known for its lightweight and insulating properties but limited biodegradability. Biodegradable food containers often utilize materials such as cornstarch, sugarcane bagasse, or polylactic acid (PLA), which decompose more rapidly under composting conditions and reduce long-term environmental impact. The molecular structure of polystyrene resists natural degradation processes, whereas biodegradable alternatives are designed with polymers that microorganisms can break down efficiently.

Environmental Impact: Styrofoam vs Biodegradable Containers

Styrofoam food containers, made from polystyrene, persist in the environment for hundreds of years, contributing significantly to landfill waste and marine pollution due to their non-biodegradable nature. In contrast, biodegradable food containers, often produced from materials like cornstarch or bamboo, break down naturally within months, reducing long-term environmental harm and lowering carbon emissions during production. Choosing biodegradable containers supports sustainable waste management practices and decreases the ecological footprint associated with food packaging.

Durability and Performance Comparison

Styrofoam food containers, made from expanded polystyrene, offer superior insulation and durability against moisture and heat, making them ideal for maintaining food temperature during transport. Biodegradable food containers, crafted from materials like cornstarch or sugarcane fiber, provide environmental benefits but often lack the same level of resilience and heat resistance, potentially compromising food protection under high temperatures or prolonged use. Performance differences impact their suitability for specific applications, with Styrofoam excelling in thermal retention and moisture barrier attributes, while biodegradable options prioritize eco-friendliness and compostability over durability.

Food Safety and Health Considerations

Styrofoam food containers, made from expanded polystyrene, pose potential health risks due to chemical leaching, especially when exposed to heat or acidic foods, which may release styrene, a possible carcinogen. Biodegradable food containers, often composed of plant-based materials like PLA or bagasse, offer safer alternatives as they do not leach harmful substances and are generally heat-resistant. Choosing biodegradable containers enhances food safety and reduces environmental impact without compromising hygiene or health standards.

Cost Analysis: Styrofoam vs Biodegradable Food Containers

Styrofoam food containers typically cost 30-50% less than biodegradable food containers, making them a popular choice for budget-conscious businesses. However, biodegradable containers, while initially more expensive, offer long-term savings by reducing environmental disposal fees and aligning with sustainability regulations. The cost disparity narrows as biodegradable manufacturing scales and raw material prices decrease.

Regulatory Restrictions and Compliance

Styrofoam food containers, primarily made from expanded polystyrene (EPS), face increasing regulatory restrictions due to environmental concerns over non-biodegradability and landfill persistence, with many municipalities banning or limiting their use. Biodegradable food containers, typically composed of materials like cornstarch, PLA, or bagasse, comply with evolving regulations aimed at reducing plastic waste and meeting compostability standards set by organizations such as ASTM International and the European Union. Compliance with these regulatory frameworks is crucial for manufacturers and food service providers striving to avoid fines and support sustainable packaging initiatives.

Consumer Perception and Market Trends

Consumer perception favors biodegradable food containers over Styrofoam due to increasing environmental awareness and concerns about plastic pollution and health risks associated with polystyrene. Market trends indicate a significant shift towards sustainable packaging, driven by government regulations and growing demand for eco-friendly alternatives in the foodservice industry. Biodegradable containers, made from plant-based materials like cornstarch or sugarcane bagasse, are gaining rapid adoption as they align with corporate social responsibility goals and attract eco-conscious consumers.

End-of-Life: Recycling and Composting Options

Styrofoam food containers, made from expanded polystyrene (EPS), face significant recycling challenges due to their low density and contamination risk, leading to a high landfill disposal rate. Biodegradable food containers, often composed of plant-based materials like PLA or bagasse, support composting in industrial facilities, enabling organic waste conversion into nutrient-rich soil amendments. End-of-life management of biodegradable containers typically results in reduced environmental impact compared to the non-biodegradable and non-compostable nature of Styrofoam.

Choosing the Right Food Container for Sustainability

Styrofoam food containers, made from polystyrene, are lightweight and inexpensive but pose significant environmental challenges due to their non-biodegradable nature and difficulty in recycling. Biodegradable food containers, often composed of materials like cornstarch, sugarcane bagasse, or PLA, decompose naturally within months, reducing landfill waste and greenhouse gas emissions. Choosing biodegradable options supports sustainability by minimizing plastic pollution and promoting eco-friendly disposal methods.

Styrofoam Food Container vs Biodegradable Food Container Infographic

materialdif.com

materialdif.com