Polystyrene beads are small, lightweight, and spherical, offering superior cushioning and flexibility for packaging and insulation applications. Polystyrene pellets are larger, denser, and more uniform in shape, providing enhanced structural stability for manufacturing processes such as injection molding. Choosing between beads and pellets depends on the specific requirements for impact resistance, density, and ease of processing in your project.

Table of Comparison

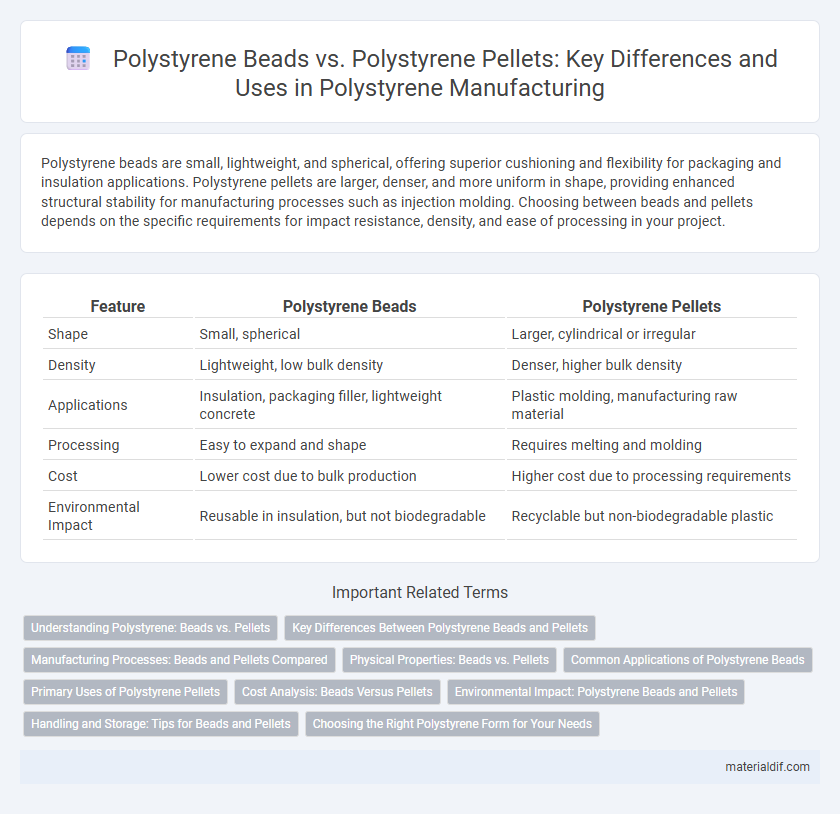

| Feature | Polystyrene Beads | Polystyrene Pellets |

|---|---|---|

| Shape | Small, spherical | Larger, cylindrical or irregular |

| Density | Lightweight, low bulk density | Denser, higher bulk density |

| Applications | Insulation, packaging filler, lightweight concrete | Plastic molding, manufacturing raw material |

| Processing | Easy to expand and shape | Requires melting and molding |

| Cost | Lower cost due to bulk production | Higher cost due to processing requirements |

| Environmental Impact | Reusable in insulation, but not biodegradable | Recyclable but non-biodegradable plastic |

Understanding Polystyrene: Beads vs. Pellets

Polystyrene beads are small, spherical particles commonly used in packaging, insulation, and craft applications due to their lightweight and insulating properties. In contrast, polystyrene pellets are slightly larger, denser granules primarily used as raw material in plastic molding and manufacturing processes for making durable consumer products. Understanding the physical differences and specific uses of polystyrene beads and pellets helps optimize material selection for industrial and commercial applications.

Key Differences Between Polystyrene Beads and Pellets

Polystyrene beads are typically smaller, spherical particles primarily used in insulation and packaging, offering superior lightweight and cushioning properties, while polystyrene pellets are larger, uniform granules designed for easier melting and molding in manufacturing processes. Beads provide better expansion capabilities in foam production compared to pellets, which are preferred for efficient injection molding due to their consistent size and shape. The choice between beads and pellets depends on the specific application requirements, such as insulation needs or precision in molded product fabrication.

Manufacturing Processes: Beads and Pellets Compared

Polystyrene beads are produced through suspension polymerization, resulting in small, spherical particles ideal for molding and insulation. Polystyrene pellets undergo extrusion and chopping, creating uniformly shaped granules suited for injection molding and compounding. The manufacturing process for beads emphasizes controlled polymerization kinetics, while pellet production focuses on precise melting and shaping for consistent feedstock in manufacturing.

Physical Properties: Beads vs. Pellets

Polystyrene beads exhibit a spherical shape with a smooth surface, providing uniformity in size and excellent flow characteristics, making them ideal for injection molding and foam production. Polystyrene pellets, on the other hand, are typically irregular or cylindrical with a rougher texture, enhancing their melting rate and blending efficiency during extrusion and extrusion processes. The density of pellets is generally higher than beads, offering greater compactness and stability for industrial manufacturing uses.

Common Applications of Polystyrene Beads

Polystyrene beads are widely used in insulation panels, packaging materials, and lightweight concrete due to their excellent thermal resistance and cushioning properties. Unlike pellets, beads offer greater flexibility in molding and expansion, making them ideal for expanded polystyrene foam products. Common applications include bean bag fillers, craft materials, and loose-fill packaging to protect fragile goods during shipping.

Primary Uses of Polystyrene Pellets

Polystyrene pellets are primarily used in injection molding and extrusion processes to manufacture a wide range of products, including packaging materials, disposable cutlery, and insulation panels. Their uniform size and shape allow for efficient melting and molding, making them ideal for producing precise and consistent plastic items. Compared to polystyrene beads, pellets offer better flow characteristics and are preferred in industrial manufacturing for large-scale production.

Cost Analysis: Beads Versus Pellets

Polystyrene beads generally incur lower initial costs due to their smaller size and ease of transportation, making them ideal for lightweight packaging and insulation applications. In contrast, polystyrene pellets often require higher handling and processing expenses but provide better material efficiency and reduced waste during manufacturing. Overall, choosing between beads and pellets hinges on balancing upfront material costs with long-term processing savings and application-specific performance.

Environmental Impact: Polystyrene Beads and Pellets

Polystyrene beads and pellets both pose environmental challenges due to their persistence and potential for marine pollution, but beads often spread more easily in aquatic environments because of their smaller size, increasing ingestion risks for wildlife. Pellets, while larger and less prone to immediate dispersion, can accumulate in significant quantities on shorelines, contributing to long-term plastic contamination. Both forms resist biodegradation, leading to prolonged ecosystem disruption and microplastic formation.

Handling and Storage: Tips for Beads and Pellets

Polystyrene beads require careful handling to prevent static buildup and contamination, ideally stored in airtight containers to maintain cleanliness and prevent moisture absorption. Polystyrene pellets, being larger and less prone to static, are easier to transport and store in bulk, typically kept in sealed bags or bins to avoid dust exposure. Both forms benefit from cool, dry storage conditions to preserve material integrity and optimize performance in manufacturing processes.

Choosing the Right Polystyrene Form for Your Needs

Polystyrene beads offer lightweight properties and excellent cushioning, making them ideal for packaging and bean bag fillers, while polystyrene pellets provide higher density and better durability for molding and manufacturing applications. Selecting the right polystyrene form depends on balancing factors like structural requirements, insulation needs, and handling convenience. Understanding the specific physical characteristics and end-use applications of beads versus pellets ensures optimal performance and cost-efficiency.

Polystyrene Beads vs Polystyrene Pellets Infographic

materialdif.com

materialdif.com