Flame-retardant polystyrene incorporates chemical additives that reduce its flammability, making it safer for applications requiring fire resistance compared to non-flame-retardant polystyrene. Non-flame-retardant polystyrene is more prone to ignition and rapid combustion, posing higher fire risks in environments without fire safety measures. Selecting flame-retardant polystyrene enhances fire safety compliance, especially in construction and electronics packaging.

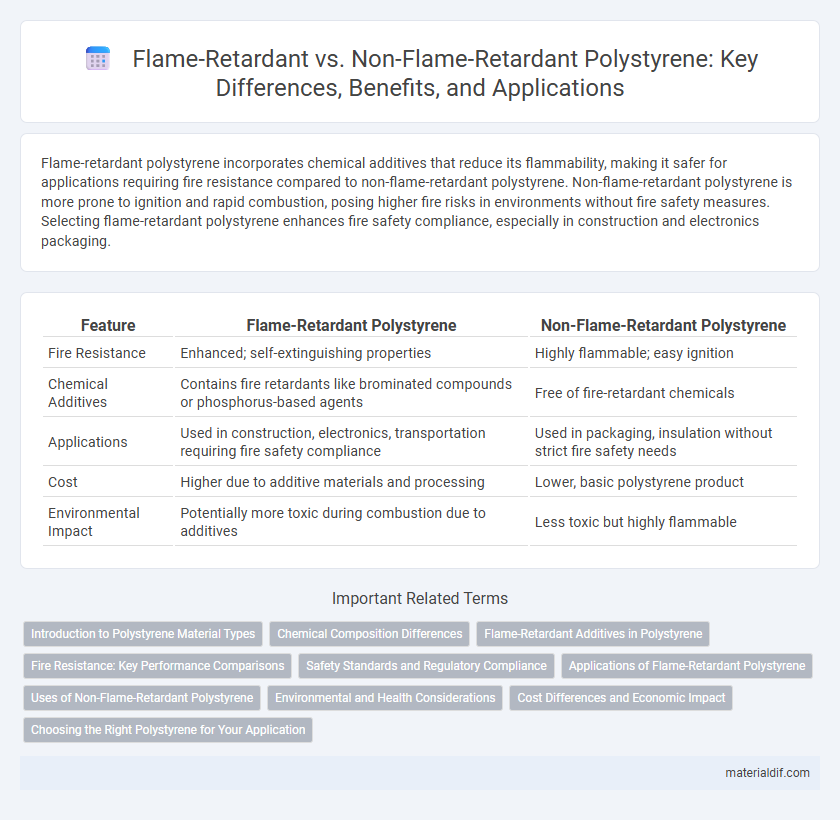

Table of Comparison

| Feature | Flame-Retardant Polystyrene | Non-Flame-Retardant Polystyrene |

|---|---|---|

| Fire Resistance | Enhanced; self-extinguishing properties | Highly flammable; easy ignition |

| Chemical Additives | Contains fire retardants like brominated compounds or phosphorus-based agents | Free of fire-retardant chemicals |

| Applications | Used in construction, electronics, transportation requiring fire safety compliance | Used in packaging, insulation without strict fire safety needs |

| Cost | Higher due to additive materials and processing | Lower, basic polystyrene product |

| Environmental Impact | Potentially more toxic during combustion due to additives | Less toxic but highly flammable |

Introduction to Polystyrene Material Types

Flame-retardant polystyrene incorporates chemical additives such as brominated or phosphorus-based compounds to inhibit ignition and slow combustion, enhancing safety in applications with fire risk. Non-flame-retardant polystyrene lacks these additives, resulting in higher flammability and faster burning rates under exposure to heat or flame. Different grades include general-purpose, high-impact, and flame-retardant types, each tailored to specific performance and safety requirements in insulation, packaging, and consumer products.

Chemical Composition Differences

Flame-retardant polystyrene contains additives such as brominated compounds, antimony trioxide, or phosphorus-based chemicals that chemically inhibit combustion by disrupting the free radical chain reactions during burning. Non-flame-retardant polystyrene lacks these specialized chemical additives, consisting primarily of the polystyrene polymer chain with hydrocarbon monomers. The presence of flame-retardant additives significantly alters the chemical composition, providing enhanced thermal stability and reduced flammability compared to standard polystyrene.

Flame-Retardant Additives in Polystyrene

Flame-retardant polystyrene incorporates additives such as brominated compounds, antimony trioxide, and phosphorus-based chemicals to inhibit ignition and slow combustion. These additives chemically interfere with the polymer's thermal degradation process, enhancing fire resistance without compromising mechanical properties. Non-flame-retardant polystyrene lacks these specialized additives, resulting in higher flammability and faster heat release during exposure to fire.

Fire Resistance: Key Performance Comparisons

Flame-retardant polystyrene incorporates chemical additives such as brominated compounds that significantly enhance its fire resistance by reducing flammability and slowing ignition times. Non-flame-retardant polystyrene, composed primarily of hydrocarbon polymers, is highly combustible with rapid ignition and produces toxic smoke during combustion. Key performance comparisons indicate flame-retardant polystyrene achieves higher UL 94 ratings and lower heat release rates, making it suitable for applications demanding stringent fire safety standards.

Safety Standards and Regulatory Compliance

Flame-retardant polystyrene meets stringent safety standards such as UL 94 V-0 and EN 13501-1, reducing flammability and limiting smoke production during combustion, which enhances fire safety in building and electrical applications. Non-flame-retardant polystyrene typically fails to comply with these regulations, posing higher fire hazards and limiting its use in environments requiring fire resistance certifications. Regulatory compliance for flame-retardant variants ensures adherence to international codes, contributing to safer product usage and reduced risk of fire-related incidents.

Applications of Flame-Retardant Polystyrene

Flame-retardant polystyrene is extensively used in building insulation, electrical housings, and automotive components due to its enhanced fire resistance and compliance with safety standards. This specialized polystyrene variant reduces flame propagation, making it ideal for use in construction materials, consumer electronics, and public transportation interiors where fire safety regulations are stringent. Incorporating flame retardants improves the polymer's performance in demanding environments without compromising its lightweight and insulating properties.

Uses of Non-Flame-Retardant Polystyrene

Non-flame-retardant polystyrene is widely used in packaging materials, disposable food containers, and insulation due to its lightweight, rigidity, and excellent thermal insulation properties. It is also commonly utilized in model making, CD cases, and other consumer products where fire resistance is not a primary concern. The economic advantage and ease of molding make non-flame-retardant polystyrene ideal for applications requiring low-cost, versatile plastic solutions.

Environmental and Health Considerations

Flame-retardant polystyrene contains additives such as brominated flame retardants, which pose environmental threats through persistent organic pollutants and potential bioaccumulation. Non-flame-retardant polystyrene avoids these chemicals but presents higher flammability risks, potentially increasing fire hazards in use. Both types require careful disposal methods to minimize release of toxic substances, with flame-retardant variants demanding stricter regulations due to their chemical composition.

Cost Differences and Economic Impact

Flame-retardant polystyrene incurs higher manufacturing costs due to the incorporation of specialized flame-retardant additives, resulting in an increased market price compared to non-flame-retardant variants. The economic impact includes higher upfront material expenses for industries such as construction and electronics, which demand stringent fire safety standards. However, investing in flame-retardant polystyrene can reduce potential fire-related losses and insurance costs, offering long-term economic benefits despite the initial cost premium.

Choosing the Right Polystyrene for Your Application

Flame-retardant polystyrene contains additives that significantly reduce its flammability, making it ideal for applications requiring enhanced fire safety compliance such as electrical insulation and building materials. Non-flame-retardant polystyrene offers better clarity and is more suitable for packaging, disposable containers, and other consumer goods where fire resistance is not a critical factor. Selecting the right polystyrene depends on the specific fire safety regulations and performance requirements of the intended application.

Flame-retardant polystyrene vs Non-flame-retardant polystyrene Infographic

materialdif.com

materialdif.com