Crystal polystyrene offers superior clarity and gloss compared to normal polystyrene, making it ideal for applications requiring high transparency and aesthetic appeal. Its enhanced thermal stability allows for better performance in temperature-sensitive environments. Compared to normal polystyrene, crystal polystyrene also exhibits improved resistance to chemicals and physical impact.

Table of Comparison

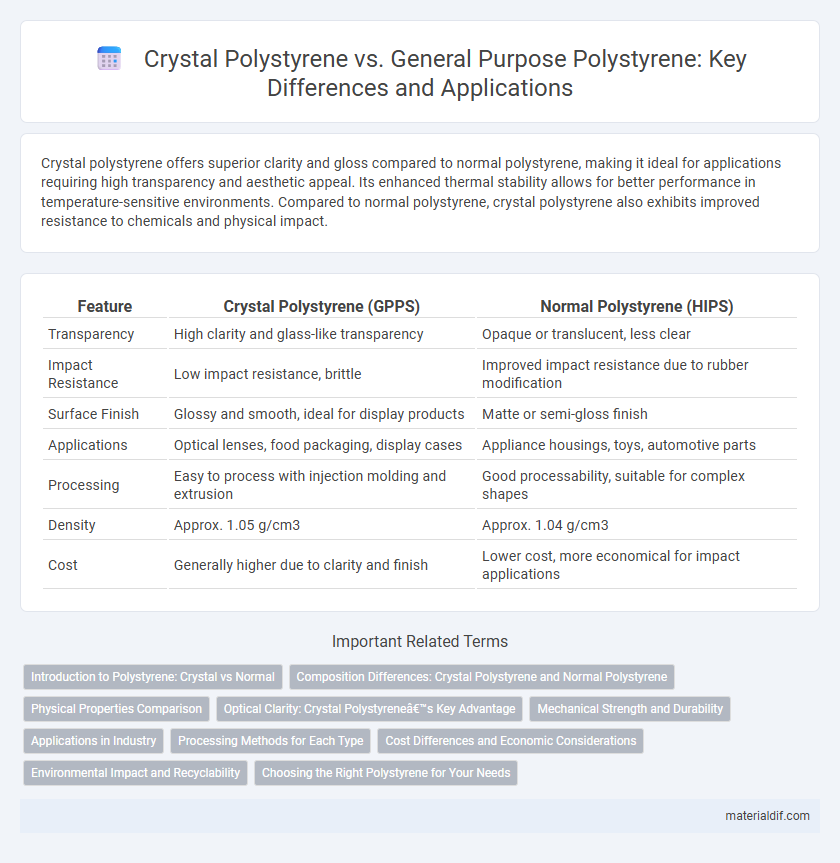

| Feature | Crystal Polystyrene (GPPS) | Normal Polystyrene (HIPS) |

|---|---|---|

| Transparency | High clarity and glass-like transparency | Opaque or translucent, less clear |

| Impact Resistance | Low impact resistance, brittle | Improved impact resistance due to rubber modification |

| Surface Finish | Glossy and smooth, ideal for display products | Matte or semi-gloss finish |

| Applications | Optical lenses, food packaging, display cases | Appliance housings, toys, automotive parts |

| Processing | Easy to process with injection molding and extrusion | Good processability, suitable for complex shapes |

| Density | Approx. 1.05 g/cm3 | Approx. 1.04 g/cm3 |

| Cost | Generally higher due to clarity and finish | Lower cost, more economical for impact applications |

Introduction to Polystyrene: Crystal vs Normal

Crystal polystyrene, a transparent variant of polystyrene, offers superior clarity and glossy finish compared to normal, opaque polystyrene commonly used in packaging and disposable products. Normal polystyrene, often referred to as general-purpose polystyrene (GPPS), provides rigidity and impact resistance but lacks the optical transparency that crystal polystyrene delivers. These differences arise from variations in polymer chain arrangement and processing, influencing applications in displays, consumer goods, and food containers.

Composition Differences: Crystal Polystyrene and Normal Polystyrene

Crystal Polystyrene is primarily composed of high-purity, transparent styrene monomers, resulting in a clear and glossy material, whereas normal polystyrene typically contains additional copolymers or fillers that affect its opacity and mechanical properties. The molecular structure of Crystal Polystyrene is more uniform and less branched, enhancing its clarity and rigidity compared to the more amorphous and flexible structure of normal polystyrene. These compositional differences lead to distinct applications, with Crystal Polystyrene favored for optical clarity and aesthetic appeal, while normal polystyrene suits more general-purpose uses.

Physical Properties Comparison

Crystal Polystyrene exhibits higher transparency and enhanced surface hardness compared to normal polystyrene, making it ideal for applications requiring clarity and durability. Its tensile strength is slightly improved, while maintaining similar thermal resistance and impact strength to general-purpose polystyrene. The enhanced rigidity and stiffness of crystal polystyrene contribute to its superior dimensional stability under mechanical stress.

Optical Clarity: Crystal Polystyrene’s Key Advantage

Crystal Polystyrene exhibits superior optical clarity compared to normal polystyrene, making it ideal for applications requiring transparent and glossy finishes. Its high light transmission rate enhances product aesthetics in packaging, displays, and consumer goods. This clarity results from a more refined polymer structure and reduced impurities, setting crystal polystyrene apart in industries prioritizing visual appeal.

Mechanical Strength and Durability

Crystal polystyrene exhibits higher mechanical strength and improved durability compared to normal polystyrene due to its enhanced molecular alignment and reduced amorphous regions. This structural difference results in better impact resistance and stiffness, making crystal polystyrene suitable for applications requiring greater load-bearing capacity. Normal polystyrene, while more flexible, lacks the robustness required for high-stress environments, limiting its use in durable goods.

Applications in Industry

Crystal polystyrene, characterized by its transparency and rigidity, is widely used in applications requiring visual clarity such as packaging, display cases, and optical components. Normal polystyrene, typically opaque and more flexible, serves predominantly in insulation panels, disposable cutlery, and protective packaging. The choice between crystal and normal polystyrene hinges on industry needs for either aesthetic appeal or functional durability.

Processing Methods for Each Type

Crystal polystyrene is typically processed using injection molding and extrusion techniques to achieve its high clarity and rigidity, whereas normal polystyrene commonly utilizes foam expansion and compression molding for its lightweight and insulating properties. The processing temperatures for crystal polystyrene generally range between 190-250degC to maintain its transparency, while normal polystyrene processing can involve lower temperatures due to the incorporation of blowing agents. Understanding these distinct processing methods is crucial for optimizing the mechanical properties and applications of each polystyrene type.

Cost Differences and Economic Considerations

Crystal Polystyrene typically incurs higher production costs due to its enhanced clarity and purity, which require more refined raw materials and processing techniques compared to Normal Polystyrene. The price premium for Crystal Polystyrene impacts budget allocations in packaging and consumer goods industries where optical properties are crucial. Economic considerations weigh the added value of visual appeal against the increased expense, influencing decisions in product design and market positioning.

Environmental Impact and Recyclability

Crystal polystyrene exhibits higher clarity and rigidity compared to normal polystyrene but poses similar environmental challenges due to its non-biodegradable nature and persistence in landfills. Both types of polystyrene are recyclable; however, the recycling rate remains low globally because of contamination issues and limited facilities equipped for polystyrene processing. Efforts to improve recycling technologies and increase collection can mitigate the environmental impact of both crystal and normal polystyrene.

Choosing the Right Polystyrene for Your Needs

Crystal polystyrene offers superior clarity and rigidity compared to normal polystyrene, making it ideal for applications requiring transparency and aesthetic appeal, such as product packaging and display cases. Normal polystyrene, known for its cost-effectiveness and versatility, suits general-purpose uses like disposable cutlery, insulation, and disposable containers. Selecting the right polystyrene depends on balancing factors like mechanical strength, visual properties, and budget constraints to meet specific project requirements effectively.

Crystal Polystyrene vs Normal Polystyrene Infographic

materialdif.com

materialdif.com