Extruded polystyrene (XPS) offers superior moisture resistance and compressive strength compared to molded polystyrene (EPS), making it ideal for insulation and structural applications. Molded polystyrene is lighter and more cost-effective, often used for packaging and disposable items due to its cushioning properties. Choosing between XPS and EPS depends on balancing durability needs with budget constraints in polystyrene pet applications.

Table of Comparison

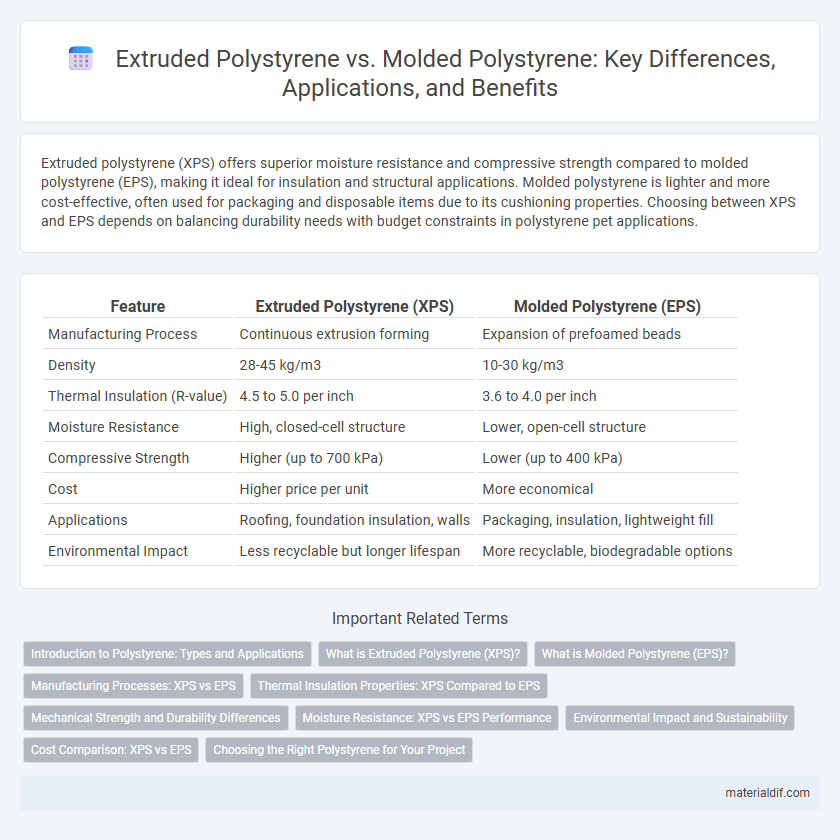

| Feature | Extruded Polystyrene (XPS) | Molded Polystyrene (EPS) |

|---|---|---|

| Manufacturing Process | Continuous extrusion forming | Expansion of prefoamed beads |

| Density | 28-45 kg/m3 | 10-30 kg/m3 |

| Thermal Insulation (R-value) | 4.5 to 5.0 per inch | 3.6 to 4.0 per inch |

| Moisture Resistance | High, closed-cell structure | Lower, open-cell structure |

| Compressive Strength | Higher (up to 700 kPa) | Lower (up to 400 kPa) |

| Cost | Higher price per unit | More economical |

| Applications | Roofing, foundation insulation, walls | Packaging, insulation, lightweight fill |

| Environmental Impact | Less recyclable but longer lifespan | More recyclable, biodegradable options |

Introduction to Polystyrene: Types and Applications

Extruded polystyrene (XPS) and molded polystyrene (EPS) are two primary types of polystyrene used in insulation and packaging, each with distinct manufacturing processes and properties. XPS is produced through a continuous extrusion process, resulting in a closed-cell structure with high compressive strength and moisture resistance, ideal for building insulation and commercial applications. EPS is created by expanding polystyrene beads and molding them into shapes, offering lightweight, excellent thermal insulation, and shock absorption, commonly used in packaging, thermal insulation panels, and disposable products.

What is Extruded Polystyrene (XPS)?

Extruded Polystyrene (XPS) is a rigid foam insulation material produced through a continuous extrusion process that creates closed-cell foam with a uniform structure. It boasts high compressive strength, low water absorption, and excellent thermal resistance, making it ideal for use in building insulation, roofing, and below-grade applications. XPS differs from Molded Polystyrene by its superior moisture resistance and durability, offering enhanced long-term performance in moisture-prone environments.

What is Molded Polystyrene (EPS)?

Molded Polystyrene, also known as Expanded Polystyrene (EPS), is a lightweight, rigid foam material commonly used for insulation, packaging, and cushioning. EPS is produced by expanding polystyrene beads with steam, which then fuse together in a mold to create a solid form with excellent thermal resistance and impact absorption properties. Its closed-cell structure makes EPS an effective moisture-resistant insulator widely employed in construction and refrigeration applications.

Manufacturing Processes: XPS vs EPS

Extruded Polystyrene (XPS) is manufactured through a continuous extrusion process that produces a closed-cell foam with consistent density and moisture resistance, making it ideal for insulation in construction. Molded Polystyrene (EPS) is created by expanding polystyrene beads within molds using steam, resulting in a lightweight, open-cell structure suitable for packaging and thermal insulation. The extrusion process of XPS offers higher compressive strength and moisture resistance compared to the bead expansion method used in EPS production.

Thermal Insulation Properties: XPS Compared to EPS

Extruded Polystyrene (XPS) offers higher thermal resistance with an R-value typically between 4.5 to 5 per inch, compared to Molded Polystyrene (EPS) which ranges from 3.6 to 4 per inch, making XPS more effective for insulation in colder climates. The closed-cell structure of XPS provides superior moisture resistance and consistent thermal performance, while EPS's open-cell structure allows for greater water absorption, potentially reducing its insulation effectiveness over time. XPS is preferred in applications requiring long-term durability and enhanced thermal insulation, especially in roofing and below-grade walls.

Mechanical Strength and Durability Differences

Extruded polystyrene (XPS) exhibits higher mechanical strength and durability compared to molded polystyrene (EPS) due to its closed-cell structure, which provides better resistance to compression and moisture absorption. XPS typically has a compressive strength ranging from 20 to 45 psi, while EPS varies from 10 to 20 psi, making XPS more suitable for load-bearing applications. The enhanced durability of XPS extends its lifespan in construction and insulation projects, especially in environments exposed to water or heavy pressure.

Moisture Resistance: XPS vs EPS Performance

Extruded polystyrene (XPS) outperforms molded polystyrene (EPS) in moisture resistance due to its closed-cell structure, resulting in lower water absorption and enhanced durability in wet conditions. XPS typically exhibits water absorption rates below 1.5%, while EPS can absorb up to 5% or more, compromising its insulation properties over time. The superior moisture resistance of XPS makes it ideal for applications requiring long-term exposure to moisture, such as below-grade insulation and roofing systems.

Environmental Impact and Sustainability

Extruded polystyrene (XPS) typically has a higher environmental impact due to the use of hydrofluorocarbon (HFC) blowing agents, which contribute to greenhouse gas emissions, while molded polystyrene (EPS) employs pentane, a less harmful blowing agent. EPS is more widely recycled and biodegradable compared to XPS, enhancing its sustainability profile in construction and packaging applications. Lifecycle assessments indicate EPS offers improved end-of-life options, reducing landfill waste and promoting circular economy practices.

Cost Comparison: XPS vs EPS

Extruded Polystyrene (XPS) typically costs more than Molded Polystyrene (EPS) due to its denser structure and higher thermal resistance, which makes it suitable for demanding insulation applications. EPS offers a more budget-friendly option with lower production costs, as it is manufactured by expanding beads of polystyrene, resulting in a lighter and less dense material. When comparing cost-effectiveness for large-scale projects, EPS tends to provide better value, while XPS's higher initial investment is often justified by its superior durability and moisture resistance.

Choosing the Right Polystyrene for Your Project

Extruded polystyrene (XPS) offers superior moisture resistance and higher compressive strength, making it ideal for insulation in foundations, roofs, and walls exposed to harsh conditions. Molded polystyrene (EPS) provides cost-effective thermal insulation with good impact resistance, suitable for packaging, lightweight fill, and interior building applications. Selecting the right polystyrene depends on project requirements such as durability, thermal performance, moisture exposure, and budget constraints to ensure optimal performance and long-term value.

Extruded Polystyrene vs Molded Polystyrene Infographic

materialdif.com

materialdif.com