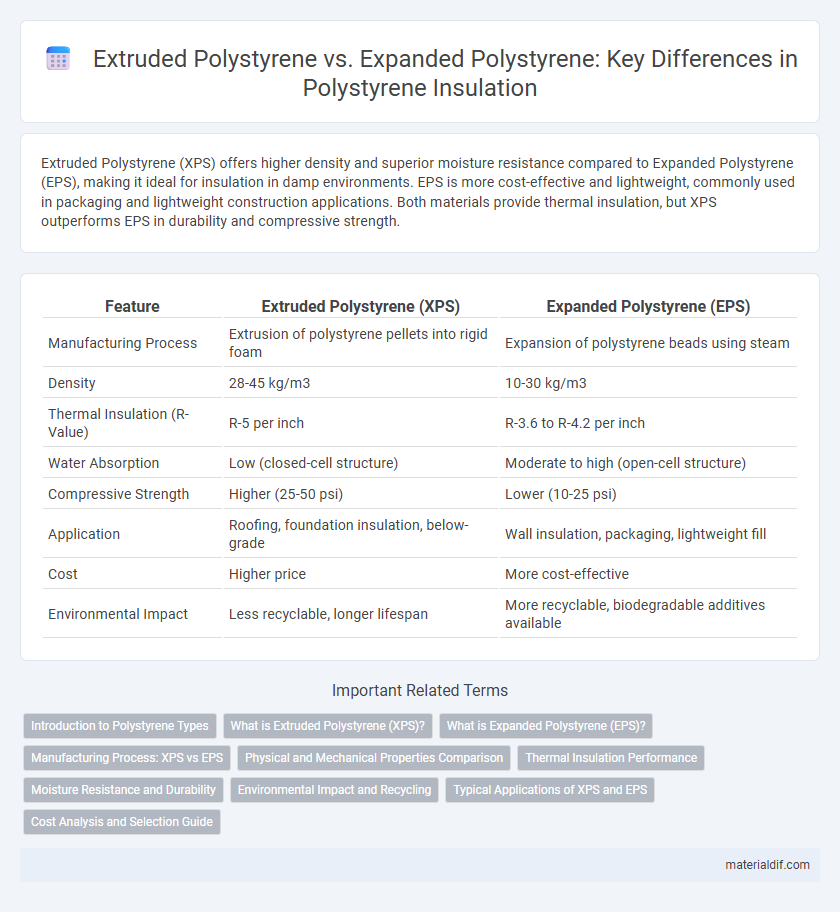

Extruded Polystyrene (XPS) offers higher density and superior moisture resistance compared to Expanded Polystyrene (EPS), making it ideal for insulation in damp environments. EPS is more cost-effective and lightweight, commonly used in packaging and lightweight construction applications. Both materials provide thermal insulation, but XPS outperforms EPS in durability and compressive strength.

Table of Comparison

| Feature | Extruded Polystyrene (XPS) | Expanded Polystyrene (EPS) |

|---|---|---|

| Manufacturing Process | Extrusion of polystyrene pellets into rigid foam | Expansion of polystyrene beads using steam |

| Density | 28-45 kg/m3 | 10-30 kg/m3 |

| Thermal Insulation (R-Value) | R-5 per inch | R-3.6 to R-4.2 per inch |

| Water Absorption | Low (closed-cell structure) | Moderate to high (open-cell structure) |

| Compressive Strength | Higher (25-50 psi) | Lower (10-25 psi) |

| Application | Roofing, foundation insulation, below-grade | Wall insulation, packaging, lightweight fill |

| Cost | Higher price | More cost-effective |

| Environmental Impact | Less recyclable, longer lifespan | More recyclable, biodegradable additives available |

Introduction to Polystyrene Types

Extruded polystyrene (XPS) features a closed-cell structure providing higher compressive strength and moisture resistance compared to expanded polystyrene (EPS), which consists of fused beads forming a lightweight, porous material. EPS offers excellent thermal insulation and is widely used in packaging and construction due to its cost-effectiveness and ease of shaping. Both XPS and EPS serve as essential polystyrene types distinguished by manufacturing processes and specific performance characteristics tailored for insulation and cushioning applications.

What is Extruded Polystyrene (XPS)?

Extruded Polystyrene (XPS) is a rigid foam insulation material manufactured through a continuous extrusion process that produces closed-cell foam with uniform density. XPS offers superior moisture resistance, compressive strength, and thermal performance compared to Expanded Polystyrene (EPS). Commonly used in building insulation, roofing, and cold storage, XPS provides enhanced durability and energy efficiency in various construction applications.

What is Expanded Polystyrene (EPS)?

Expanded Polystyrene (EPS) is a lightweight, rigid foam material composed of pre-expanded polystyrene beads fused together through heat, commonly used for insulation and packaging. EPS offers excellent thermal resistance, moisture resistance, and shock absorption, making it ideal for energy-efficient building applications and protective packaging solutions. Its closed-cell structure provides high compressive strength and durability, differentiating it from Extruded Polystyrene (XPS) with regards to manufacturing process and performance characteristics.

Manufacturing Process: XPS vs EPS

Extruded polystyrene (XPS) is manufactured through a continuous extrusion process that involves melting polystyrene crystals combined with blowing agents, producing a closed-cell foam with uniform structure and higher density. Expanded polystyrene (EPS) is created by pre-expanding polystyrene beads using steam, followed by molding and fusing the beads into a cellular foam with an open-cell structure and variable density. The extrusion process of XPS allows for improved moisture resistance and compression strength compared to the bead-fusion manufacturing of EPS.

Physical and Mechanical Properties Comparison

Extruded Polystyrene (XPS) exhibits higher compressive strength and lower water absorption compared to Expanded Polystyrene (EPS), making XPS more suitable for load-bearing applications and moisture-prone environments. EPS has a more open-cell structure, resulting in lower density and better impact resistance but reduced thermal insulation efficiency relative to the closed-cell structure of XPS. The thermal conductivity of XPS typically ranges from 0.029 to 0.036 W/m*K, which is superior to EPS's 0.035 to 0.045 W/m*K, indicating better insulation performance for XPS in construction and packaging uses.

Thermal Insulation Performance

Extruded polystyrene (XPS) offers superior thermal insulation performance compared to expanded polystyrene (EPS) due to its closed-cell structure, resulting in lower thermal conductivity values typically around 0.029-0.035 W/m*K. EPS, with its open-cell structure, generally exhibits higher thermal conductivity ranging between 0.035-0.040 W/m*K, making XPS more effective in maintaining consistent insulating properties under moisture exposure. Both materials serve insulation purposes, but XPS's enhanced durability and moisture resistance contribute to longer-lasting thermal performance in building applications.

Moisture Resistance and Durability

Extruded Polystyrene (XPS) exhibits superior moisture resistance due to its closed-cell structure, making it less prone to water absorption compared to Expanded Polystyrene (EPS), which has an open-cell composition. The enhanced durability of XPS allows it to maintain thermal performance and structural integrity in damp environments, ideal for use in below-grade insulation and roofing. EPS, while cost-effective and lightweight, tends to degrade faster under prolonged exposure to moisture, limiting its application in high-moisture conditions.

Environmental Impact and Recycling

Extruded polystyrene (XPS) and expanded polystyrene (EPS) differ significantly in environmental impact and recycling potential. EPS is more widely recycled due to its lower density and broader acceptance in recycling programs, while XPS, containing more additives and a closed-cell structure, poses greater challenges for recycling and tends to generate more persistent waste. Both materials contribute to environmental concerns, but EPS offers slightly better prospects for sustainable disposal and reuse in insulation and packaging applications.

Typical Applications of XPS and EPS

Extruded Polystyrene (XPS) is commonly used in rigid foam insulation for walls, roofs, and foundations due to its high compressive strength and moisture resistance. Expanded Polystyrene (EPS) is often utilized in packaging, insulation boards, and structural fill because of its lightweight properties and thermal insulation efficiency. Both materials serve critical roles in construction and packaging industries, but XPS is preferred for applications requiring durability and moisture barriers, while EPS is favored for cost-effective insulation and cushioning.

Cost Analysis and Selection Guide

Extruded Polystyrene (XPS) generally costs more upfront than Expanded Polystyrene (EPS) due to its denser structure and superior insulation properties. EPS offers a lower initial investment and sufficient thermal resistance for many applications, making it a cost-effective option for budget-sensitive projects. Selection between XPS and EPS should weigh factors like long-term energy savings, moisture resistance, and project-specific insulation requirements to optimize cost-efficiency and performance.

Extruded Polystyrene vs Expanded Polystyrene Infographic

materialdif.com

materialdif.com