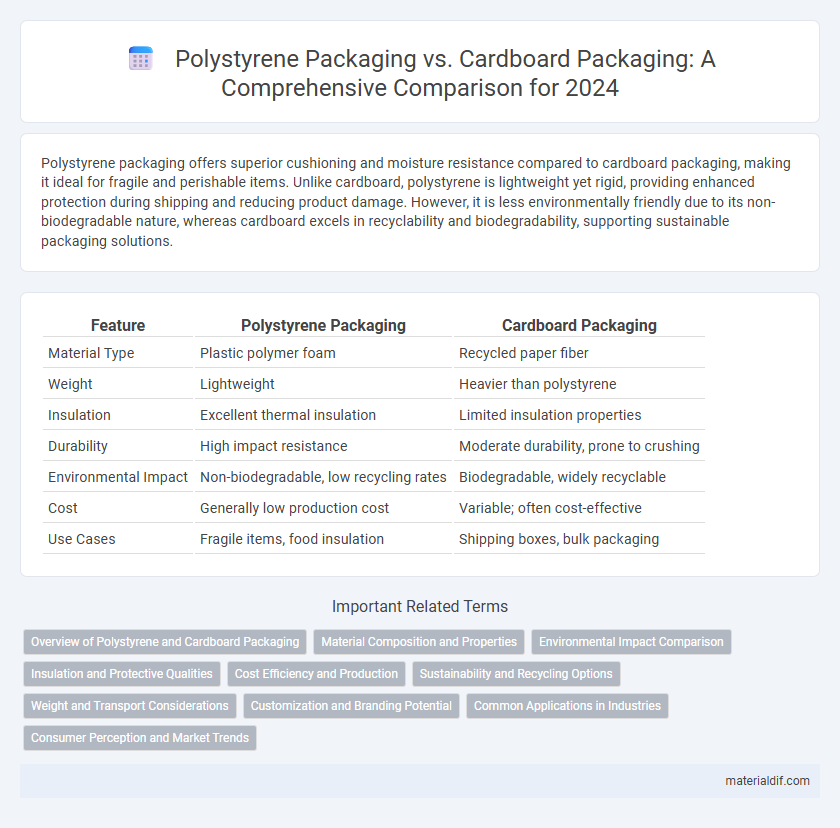

Polystyrene packaging offers superior cushioning and moisture resistance compared to cardboard packaging, making it ideal for fragile and perishable items. Unlike cardboard, polystyrene is lightweight yet rigid, providing enhanced protection during shipping and reducing product damage. However, it is less environmentally friendly due to its non-biodegradable nature, whereas cardboard excels in recyclability and biodegradability, supporting sustainable packaging solutions.

Table of Comparison

| Feature | Polystyrene Packaging | Cardboard Packaging |

|---|---|---|

| Material Type | Plastic polymer foam | Recycled paper fiber |

| Weight | Lightweight | Heavier than polystyrene |

| Insulation | Excellent thermal insulation | Limited insulation properties |

| Durability | High impact resistance | Moderate durability, prone to crushing |

| Environmental Impact | Non-biodegradable, low recycling rates | Biodegradable, widely recyclable |

| Cost | Generally low production cost | Variable; often cost-effective |

| Use Cases | Fragile items, food insulation | Shipping boxes, bulk packaging |

Overview of Polystyrene and Cardboard Packaging

Polystyrene packaging is a lightweight, durable plastic material known for its excellent insulation properties and resistance to moisture, making it ideal for protecting fragile items and perishable goods during shipping. Cardboard packaging, derived from paper pulp, is biodegradable, recyclable, and widely used for its versatility, structural strength, and cost-effectiveness in shipping and storage. While polystyrene excels in cushioning and thermal insulation, cardboard offers superior environmental benefits through recyclability and compostability.

Material Composition and Properties

Polystyrene packaging is composed of a synthetic aromatic hydrocarbon polymer derived from styrene monomers, offering superior rigidity, moisture resistance, and thermal insulation compared to cardboard packaging, which is made from cellulose fibers derived from wood pulp and provides greater breathability and biodegradability. Polystyrene's closed-cell structure enhances its cushioning and shock absorption capabilities, making it ideal for fragile items, whereas cardboard's porous and fibrous matrix facilitates recyclability and compostability but lacks significant water resistance. The denser molecular structure of polystyrene contributes to its higher durability and resistance to chemicals, while cardboard's layered construction allows for easy customization and printing versatility.

Environmental Impact Comparison

Polystyrene packaging produces significantly more non-biodegradable waste, leading to long-lasting environmental pollution compared to cardboard, which is biodegradable and more easily recyclable. The production of polystyrene involves petrochemicals and releases higher greenhouse gas emissions, whereas cardboard manufacturing typically uses renewable resources with a lower carbon footprint. Polystyrene's environmental persistence contributes to marine litter and soil contamination, while cardboard decomposes rapidly, reducing ecological harm.

Insulation and Protective Qualities

Polystyrene packaging offers superior insulation properties due to its closed-cell structure, effectively maintaining temperature control for perishable goods during transit. Its lightweight yet rigid nature provides excellent shock absorption and impact resistance, safeguarding fragile items better than cardboard packaging. In contrast, cardboard packaging typically allows more heat transfer and is less effective at protecting against moisture and physical shocks.

Cost Efficiency and Production

Polystyrene packaging offers superior cost efficiency due to lower raw material and manufacturing expenses compared to cardboard packaging, resulting in reduced overall production costs. Its lightweight nature decreases transportation expenses and enhances handling efficiency in mass production lines. However, cardboard packaging, while often more expensive initially, provides better recyclability and environmental sustainability, influencing long-term cost considerations in production planning.

Sustainability and Recycling Options

Polystyrene packaging offers excellent insulation and lightweight properties but poses significant challenges for sustainability due to its non-biodegradable nature and limited recycling infrastructure. Cardboard packaging, made from renewable resources, is widely accepted in recycling programs and decomposes more readily in natural environments. Choosing cardboard over polystyrene reduces environmental impact through greater recyclability and lower carbon footprint associated with production and disposal.

Weight and Transport Considerations

Polystyrene packaging offers a significantly lighter weight compared to cardboard packaging, reducing overall shipping costs and easing handling during transport. Its low density and high cushioning properties minimize damage risks while enhancing fuel efficiency for logistics operations. Despite cardboard's recyclability advantages, polystyrene's lightweight nature makes it a preferred choice for fragile goods requiring efficient, cost-effective transportation.

Customization and Branding Potential

Polystyrene packaging offers superior customization options with its ability to be molded into various shapes and sizes, accommodating detailed logos and intricate brand designs. Cardboard packaging allows for high-quality printed graphics and eco-friendly branding messages, appealing to sustainability-conscious consumers. Both materials support impactful branding, but polystyrene excels in structural customization while cardboard prioritizes surface design versatility and environmental appeal.

Common Applications in Industries

Polystyrene packaging is widely used in the food and electronics industries due to its excellent insulation properties and impact resistance, making it ideal for protecting fragile items and maintaining temperature-sensitive goods. Cardboard packaging dominates sectors like retail and shipping because of its cost-effectiveness, recyclability, and versatility in accommodating various product shapes and weights. Both materials serve crucial roles in packaging, with polystyrene favored for cushioning and thermal insulation, while cardboard excels in eco-friendly, structural packaging solutions.

Consumer Perception and Market Trends

Polystyrene packaging is often perceived by consumers as lightweight, durable, and protective, making it popular for fragile items and electronics, while concerns about environmental impact drive many toward cardboard alternatives. Market trends show increasing demand for sustainable packaging, with cardboard's biodegradability and recyclability boosting its appeal among eco-conscious consumers and brands focused on reducing plastic waste. Despite this, polystyrene maintains a strong niche in cost-sensitive sectors due to its superior insulation and impact resistance properties.

Polystyrene Packaging vs Cardboard Packaging Infographic

materialdif.com

materialdif.com