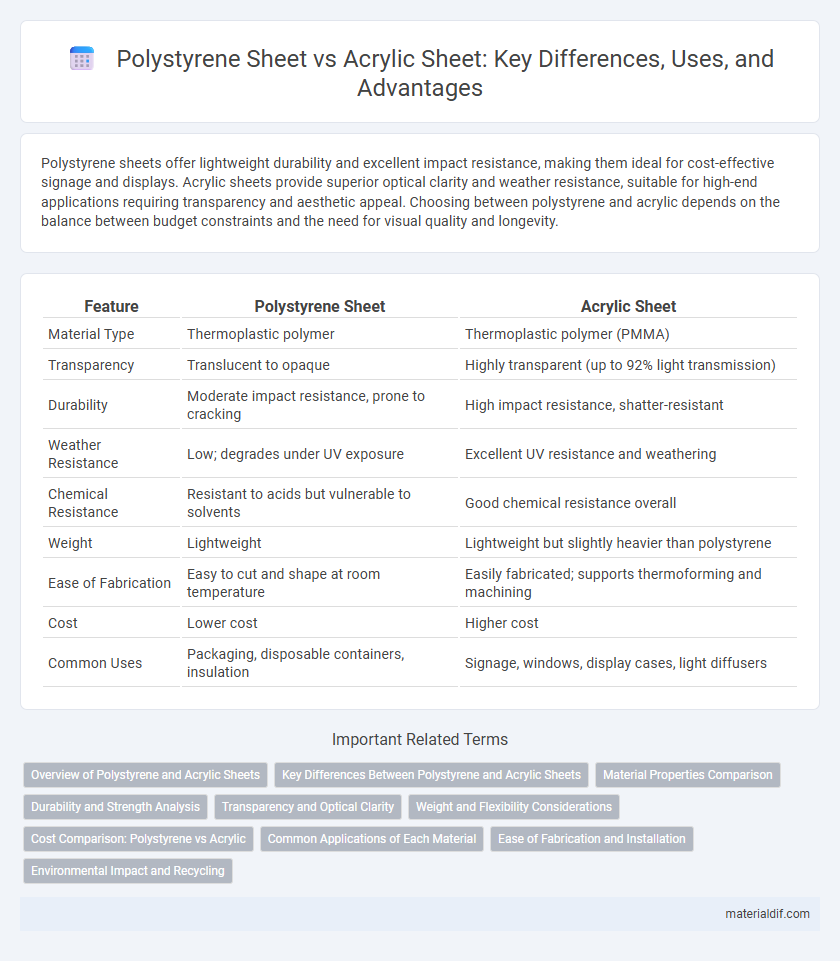

Polystyrene sheets offer lightweight durability and excellent impact resistance, making them ideal for cost-effective signage and displays. Acrylic sheets provide superior optical clarity and weather resistance, suitable for high-end applications requiring transparency and aesthetic appeal. Choosing between polystyrene and acrylic depends on the balance between budget constraints and the need for visual quality and longevity.

Table of Comparison

| Feature | Polystyrene Sheet | Acrylic Sheet |

|---|---|---|

| Material Type | Thermoplastic polymer | Thermoplastic polymer (PMMA) |

| Transparency | Translucent to opaque | Highly transparent (up to 92% light transmission) |

| Durability | Moderate impact resistance, prone to cracking | High impact resistance, shatter-resistant |

| Weather Resistance | Low; degrades under UV exposure | Excellent UV resistance and weathering |

| Chemical Resistance | Resistant to acids but vulnerable to solvents | Good chemical resistance overall |

| Weight | Lightweight | Lightweight but slightly heavier than polystyrene |

| Ease of Fabrication | Easy to cut and shape at room temperature | Easily fabricated; supports thermoforming and machining |

| Cost | Lower cost | Higher cost |

| Common Uses | Packaging, disposable containers, insulation | Signage, windows, display cases, light diffusers |

Overview of Polystyrene and Acrylic Sheets

Polystyrene sheets are lightweight, rigid thermoplastic materials known for their excellent clarity, impact resistance, and ease of fabrication, making them ideal for packaging, displays, and insulation. Acrylic sheets, also called polymethyl methacrylate (PMMA), offer superior optical clarity, UV resistance, and weatherability, often used in signage, windows, and protective barriers. Both materials serve versatile applications, but polystyrene is typically more cost-effective while acrylic provides enhanced durability and outdoor performance.

Key Differences Between Polystyrene and Acrylic Sheets

Polystyrene sheets are lightweight, cost-effective, and offer good impact resistance, making them suitable for packaging and model-making applications. Acrylic sheets provide superior optical clarity, UV resistance, and higher strength, making them ideal for signage, displays, and outdoor uses. Polystyrene is easier to thermoform but less durable, whereas acrylic is more rigid, scratch-resistant, and weather-resistant.

Material Properties Comparison

Polystyrene sheets offer excellent impact resistance and are lightweight, making them ideal for budget-friendly applications, while acrylic sheets provide superior clarity, higher scratch resistance, and better UV stability suitable for outdoor use. Acrylic exhibits greater tensile strength and thermal resistance compared to polystyrene, which tends to be more brittle under prolonged stress or exposure to sunlight. The choice between polystyrene and acrylic sheets depends on specific performance requirements such as durability, transparency, and environmental resistance.

Durability and Strength Analysis

Polystyrene sheets exhibit lower impact resistance and tensile strength compared to acrylic sheets, making acrylic a more durable option for applications requiring high strength and toughness. Acrylic sheets offer superior resistance to cracking and weathering, which enhances their longevity in outdoor environments. Despite polystyrene's lightweight and cost-effectiveness, acrylic's enhanced mechanical properties make it preferable for structural and high-stress uses.

Transparency and Optical Clarity

Polystyrene sheets offer moderate transparency with a slightly hazy appearance, making them suitable for applications where cost-effectiveness is prioritized over optical clarity. Acrylic sheets provide superior transparency and high optical clarity, often exceeding 92% light transmission, which ensures crystal-clear visibility and vibrant color rendition. The enhanced clarity of acrylic makes it the preferred choice for display cases, signage, and glazing where visual aesthetics are critical.

Weight and Flexibility Considerations

Polystyrene sheets are significantly lighter than acrylic sheets, making them ideal for applications requiring easy handling and reduced structural load. Polystyrene offers greater flexibility, allowing for easier bending without cracking, whereas acrylic sheets are more rigid and prone to fracturing under stress. These weight and flexibility differences influence material selection in packaging, signage, and lightweight construction projects.

Cost Comparison: Polystyrene vs Acrylic

Polystyrene sheets generally cost significantly less than acrylic sheets, making them a more budget-friendly option for large-scale projects. While acrylic offers superior clarity and durability, the lower price point of polystyrene appeals to cost-sensitive applications where impact resistance and premium aesthetics are less critical. Polystyrene's affordability stems from its simpler manufacturing process and lower raw material costs compared to acrylic polymers.

Common Applications of Each Material

Polystyrene sheets are commonly used in packaging, disposable cutlery, and insulation due to their lightweight and impact-resistant properties. Acrylic sheets find applications in signage, display cases, and skylights, valued for their clarity and weather resistance. Both materials are widely utilized in construction and advertising, with polystyrene preferred for cost-effective insulation and acrylic chosen for durable, transparent surfaces.

Ease of Fabrication and Installation

Polystyrene sheets are lightweight and can be easily cut, shaped, and glued, making them highly suitable for quick fabrication and installation in various applications. Acrylic sheets, while also versatile, require specialized tools for cutting and drilling to prevent cracking, which may extend fabrication time and complicate installation. The superior ease of handling polystyrene often results in faster project completion and reduced labor costs compared to acrylic sheets.

Environmental Impact and Recycling

Polystyrene sheets have a higher environmental impact compared to acrylic sheets due to their slower biodegradation and potential release of toxic styrene monomers during breakdown. Acrylic sheets are generally easier to recycle and have a lower carbon footprint, largely because of their durability and longer lifespan, reducing material waste over time. Both materials present recycling challenges, but acrylic's chemical stability and more established recycling infrastructure make it a more eco-friendly choice.

Polystyrene Sheet vs Acrylic Sheet Infographic

materialdif.com

materialdif.com