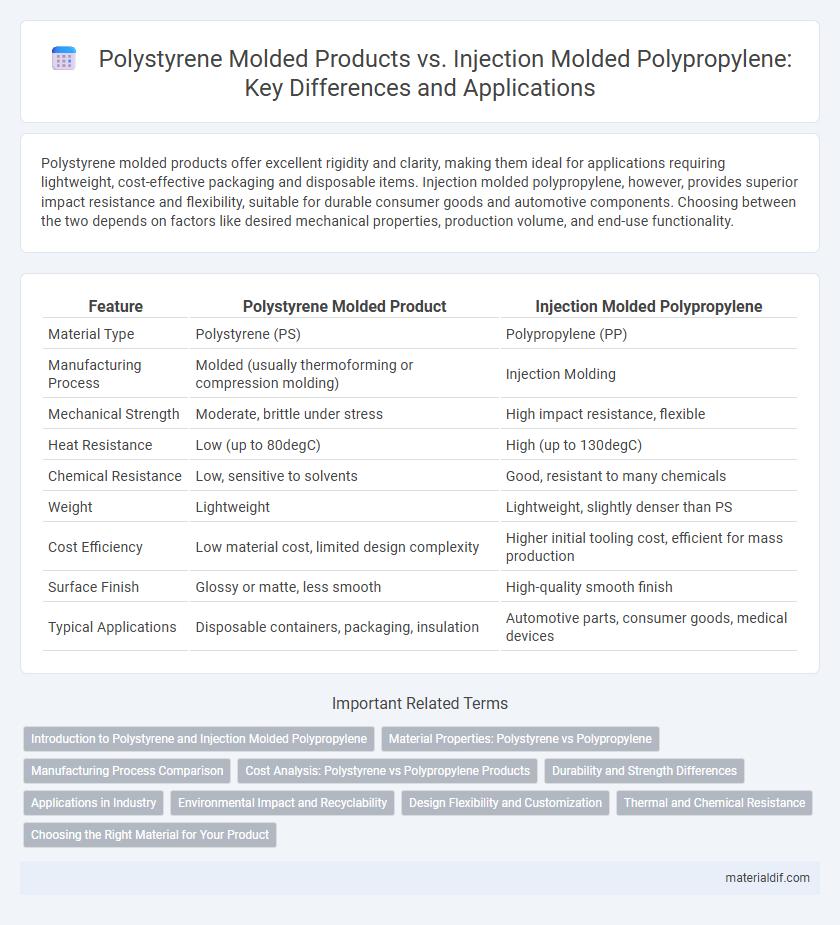

Polystyrene molded products offer excellent rigidity and clarity, making them ideal for applications requiring lightweight, cost-effective packaging and disposable items. Injection molded polypropylene, however, provides superior impact resistance and flexibility, suitable for durable consumer goods and automotive components. Choosing between the two depends on factors like desired mechanical properties, production volume, and end-use functionality.

Table of Comparison

| Feature | Polystyrene Molded Product | Injection Molded Polypropylene |

|---|---|---|

| Material Type | Polystyrene (PS) | Polypropylene (PP) |

| Manufacturing Process | Molded (usually thermoforming or compression molding) | Injection Molding |

| Mechanical Strength | Moderate, brittle under stress | High impact resistance, flexible |

| Heat Resistance | Low (up to 80degC) | High (up to 130degC) |

| Chemical Resistance | Low, sensitive to solvents | Good, resistant to many chemicals |

| Weight | Lightweight | Lightweight, slightly denser than PS |

| Cost Efficiency | Low material cost, limited design complexity | Higher initial tooling cost, efficient for mass production |

| Surface Finish | Glossy or matte, less smooth | High-quality smooth finish |

| Typical Applications | Disposable containers, packaging, insulation | Automotive parts, consumer goods, medical devices |

Introduction to Polystyrene and Injection Molded Polypropylene

Polystyrene is a versatile thermoplastic polymer known for its rigidity, clarity, and ease of molding, commonly used in packaging, disposable containers, and insulation. Injection molded polypropylene offers enhanced impact resistance, chemical stability, and flexibility, making it ideal for automotive parts, consumer goods, and medical devices. Both materials leverage injection molding processes but differ significantly in mechanical properties and typical applications due to their molecular structures and thermal characteristics.

Material Properties: Polystyrene vs Polypropylene

Polystyrene exhibits higher rigidity and better dimensional stability compared to injection molded polypropylene, making it ideal for applications requiring firm shapes and structural integrity. Polypropylene offers superior impact resistance, flexibility, and chemical resistance due to its semi-crystalline structure, which polystyrene lacks. Thermal resistance of polypropylene exceeds that of polystyrene, enabling it to withstand higher temperatures without deformation or degradation.

Manufacturing Process Comparison

Polystyrene molded products are typically produced using processes such as compression molding or casting, which allow for detailed shapes but often result in longer cycle times compared to injection molded polypropylene. Injection molding of polypropylene uses high-pressure injection of molten polymer into molds, enabling faster production rates and greater consistency in part dimensions. The choice between these manufacturing processes impacts not only production speed and cost but also the final product's mechanical properties and surface finish.

Cost Analysis: Polystyrene vs Polypropylene Products

Polystyrene molded products typically exhibit lower material costs compared to injection molded polypropylene, making them more cost-effective for high-volume production of lightweight items. However, polypropylene offers greater durability and chemical resistance, which can reduce long-term expenses despite higher initial mold and material costs. Analyzing total cost of ownership, polystyrene suits disposable or less demanding applications, whereas polypropylene justifies its investment through enhanced performance and longevity.

Durability and Strength Differences

Polystyrene molded products exhibit higher rigidity but lower impact resistance compared to injection molded polypropylene, which offers superior toughness and flexibility. Polystyrene's brittleness limits its durability under stress, whereas polypropylene's molecular structure provides enhanced fatigue resistance and resilience. This makes polypropylene more suitable for applications requiring long-term mechanical strength and durability.

Applications in Industry

Polystyrene molded products offer excellent rigidity, clarity, and impact resistance, making them ideal for packaging, disposable cutlery, and insulation applications in the food and medical industries. Injection molded polypropylene excels in automotive components, consumer goods, and household appliances due to its superior flexibility, chemical resistance, and fatigue durability. Industries select polystyrene or polypropylene molding methods based on product requirements such as transparency, strength, and environmental stress tolerance.

Environmental Impact and Recyclability

Polystyrene molded products generate significant environmental concerns due to their low biodegradability and limited recycling infrastructure, often ending up in landfills or oceans where they persist for centuries. Injection molded polypropylene offers improved environmental performance with higher recyclability rates and reduced carbon footprint during production, making it a more sustainable choice. Both materials require enhanced recycling technologies, but polypropylene's widespread acceptance in recycling programs positions it as a more eco-friendly alternative.

Design Flexibility and Customization

Polystyrene molded products offer high design flexibility due to their ease of molding into intricate shapes and detailed patterns, making them ideal for customized packaging and decorative items. Injection molded polypropylene provides superior durability and chemical resistance, with moderate customization options geared towards functional components and automotive parts. Polystyrene excels in lightweight, aesthetic-driven applications, while polypropylene is preferred for robust, performance-oriented designs.

Thermal and Chemical Resistance

Polystyrene molded products exhibit lower thermal resistance with a maximum service temperature around 80degC, whereas injection molded polypropylene withstands higher temperatures up to 120degC, making it more suitable for applications requiring heat tolerance. Chemically, polystyrene shows poor resistance to solvents like acetone and hydrocarbons, resulting in surface degradation, while polypropylene offers superior resistance to a wide range of chemicals including acids, bases, and organic solvents. The enhanced thermal and chemical resistance of injection molded polypropylene makes it ideal for demanding industrial and automotive applications compared to polystyrene molded products.

Choosing the Right Material for Your Product

Polystyrene molded products offer excellent rigidity and clarity, making them ideal for applications requiring detailed designs and transparent finishes. Injection molded polypropylene provides superior impact resistance and flexibility, suitable for durable and lightweight components. Selecting the right material depends on specific product requirements such as strength, transparency, and environmental exposure.

Polystyrene Molded Product vs Injection Molded Polypropylene Infographic

materialdif.com

materialdif.com