Polypropylene and polyethylene are both widely used polymers with distinct properties influencing their applications. Polypropylene boasts a higher melting point and greater stiffness, making it ideal for automotive parts and reusable containers, while polyethylene, especially HDPE and LDPE variants, offers superior flexibility and chemical resistance suited for packaging and plastic bags. The choice between polypropylene and polyethylene depends on factors like strength requirements, temperature resistance, and environmental durability.

Table of Comparison

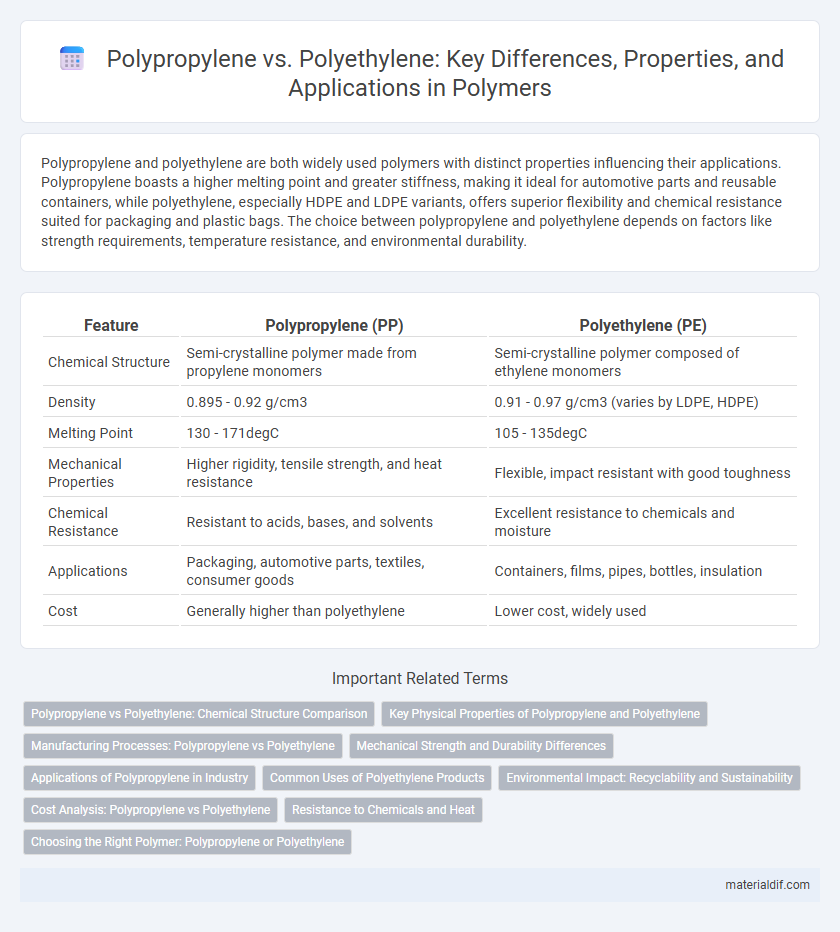

| Feature | Polypropylene (PP) | Polyethylene (PE) |

|---|---|---|

| Chemical Structure | Semi-crystalline polymer made from propylene monomers | Semi-crystalline polymer composed of ethylene monomers |

| Density | 0.895 - 0.92 g/cm3 | 0.91 - 0.97 g/cm3 (varies by LDPE, HDPE) |

| Melting Point | 130 - 171degC | 105 - 135degC |

| Mechanical Properties | Higher rigidity, tensile strength, and heat resistance | Flexible, impact resistant with good toughness |

| Chemical Resistance | Resistant to acids, bases, and solvents | Excellent resistance to chemicals and moisture |

| Applications | Packaging, automotive parts, textiles, consumer goods | Containers, films, pipes, bottles, insulation |

| Cost | Generally higher than polyethylene | Lower cost, widely used |

Polypropylene vs Polyethylene: Chemical Structure Comparison

Polypropylene and polyethylene are both polyolefins with distinct chemical structures, where polypropylene features a methyl group (CH3) attached to every other carbon atom in its backbone, unlike polyethylene, which consists solely of repeating ethylene units (CH2). This methyl side group in polypropylene imparts increased rigidity, higher melting point (about 160degC for polypropylene versus 115degC for polyethylene), and enhanced chemical resistance. Polyethylene's simpler structure leads to greater flexibility and lower density, influencing its common use in applications requiring pliability and toughness.

Key Physical Properties of Polypropylene and Polyethylene

Polypropylene exhibits higher tensile strength and melting point, typically around 160degC, compared to polyethylene, whose melting point ranges between 105-130degC depending on type (HDPE, LDPE). Polyethylene demonstrates greater flexibility and impact resistance, with variations like HDPE offering higher density and rigidity, while LDPE provides more elasticity. Both polymers have excellent chemical resistance, but polypropylene's lower density contributes to a lighter material often favored in automotive and packaging applications.

Manufacturing Processes: Polypropylene vs Polyethylene

Polypropylene is produced through a polymerization process using Ziegler-Natta or metallocene catalysts, typically via slurry, gas-phase, or bulk polymerization methods that allow control over molecular weight and isotacticity. Polyethylene manufacturing commonly involves high-pressure free-radical polymerization for low-density polyethylene (LDPE) or catalytic processes such as Ziegler-Natta or chromium catalysts in gas-phase or solution polymerization for high-density polyethylene (HDPE). The distinct catalyst systems and polymerization conditions significantly influence the polymer chain structure, crystallinity, and mechanical properties of polypropylene versus polyethylene.

Mechanical Strength and Durability Differences

Polypropylene exhibits higher tensile strength and greater resistance to fatigue compared to polyethylene, making it ideal for applications requiring enhanced mechanical performance. Polyethylene offers superior impact resistance and flexibility, which contributes to better durability in low-temperature environments. The crystalline structure of polypropylene provides stiffness and heat resistance, whereas polyethylene's amorphous regions enhance its toughness and chemical stability.

Applications of Polypropylene in Industry

Polypropylene is widely used in automotive parts, packaging, textiles, and consumer goods due to its excellent chemical resistance, high melting point, and durability. Unlike polyethylene, polypropylene's rigidity and thermal stability make it ideal for manufacturing components such as battery cases, food containers, and medical devices. The polymer's versatility and cost-effectiveness drive its extensive application across industries including automotive, packaging, and healthcare.

Common Uses of Polyethylene Products

Polyethylene is widely used in packaging materials such as plastic bags, bottles, and containers due to its durability and flexibility. Its applications extend to agricultural films, geomembranes for environmental protection, and household goods like toys and kitchenware. This versatility stems from polyethylene's varying density grades, including low-density (LDPE) and high-density (HDPE), each suited for different industrial and consumer products.

Environmental Impact: Recyclability and Sustainability

Polypropylene (PP) and polyethylene (PE) differ significantly in environmental impact, with PE generally exhibiting higher recyclability rates due to widespread recycling infrastructure and clearer resin identification codes. While both polymers are derived from fossil fuels, advancements in recycling technologies for PE enhance its sustainability profile compared to PP, which faces challenges in mechanical recycling and lower market demand for recycled materials. Emerging biopolymers and chemical recycling methods aim to improve the sustainability of both PP and PE, yet polyethylene currently holds a marginal advantage in environmental impact through more efficient waste management systems.

Cost Analysis: Polypropylene vs Polyethylene

Polypropylene generally offers a lower production cost compared to polyethylene due to its higher melting point, which allows more energy-efficient processing. Polyethylene, especially high-density variants, tends to be more expensive owing to its versatile applications in packaging and piping that demand higher purity and density. Cost efficiency in choosing between polypropylene and polyethylene ultimately depends on the specific application requirements and volume of production.

Resistance to Chemicals and Heat

Polypropylene exhibits superior resistance to alcohols, acids, and bases compared to polyethylene, making it ideal for chemical containers and laboratory equipment. In terms of heat resistance, polypropylene maintains structural integrity at temperatures up to 160degC, outperforming polyethylene, which typically withstands temperatures only up to 120degC. The crystalline structure of polypropylene enhances its durability against chemical exposure and thermal stress, contributing to its preference in automotive and industrial applications.

Choosing the Right Polymer: Polypropylene or Polyethylene

Polypropylene offers higher tensile strength, heat resistance up to 160degC, and better chemical resistance, making it ideal for automotive parts and food containers. Polyethylene, especially HDPE and LDPE variants, excels in flexibility, impact resistance, and is commonly used in packaging, plastic bags, and piping systems. Selecting the right polymer depends on application-specific requirements such as temperature tolerance, mechanical strength, and environmental exposure.

Polypropylene vs Polyethylene Infographic

materialdif.com

materialdif.com