Polyimide offers superior thermal stability and chemical resistance compared to polyamide, making it ideal for high-performance applications such as electronics and aerospace. Polyamide, commonly known as nylon, provides excellent mechanical strength and flexibility, widely used in textiles and automotive parts. Understanding these distinct properties helps in selecting the appropriate polymer for specific industrial needs.

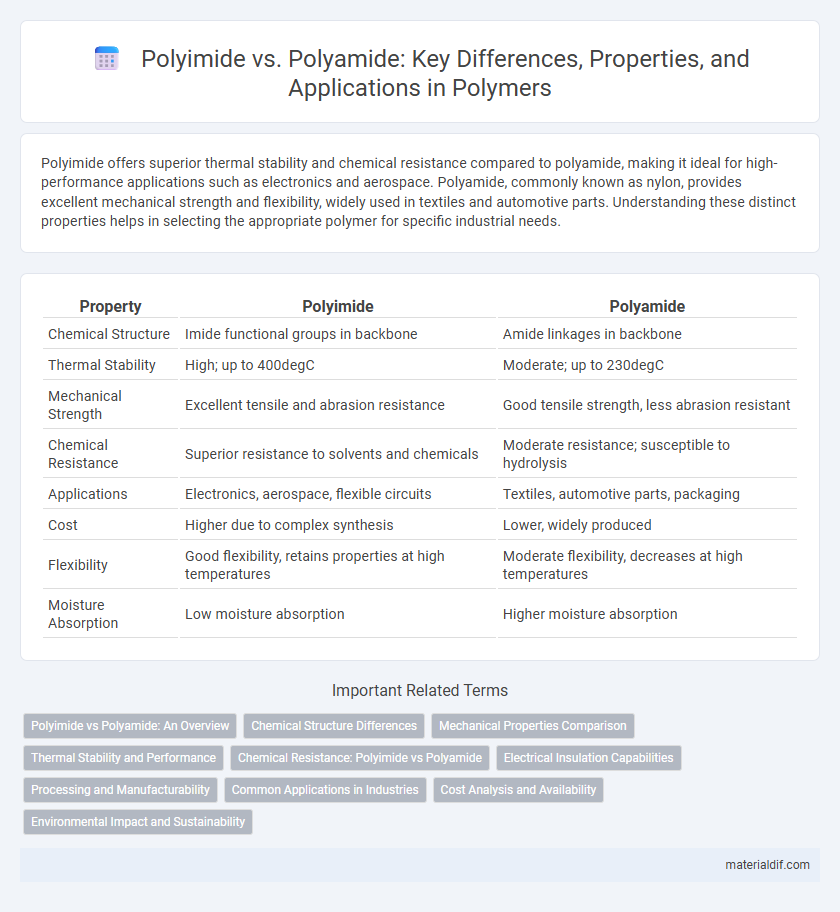

Table of Comparison

| Property | Polyimide | Polyamide |

|---|---|---|

| Chemical Structure | Imide functional groups in backbone | Amide linkages in backbone |

| Thermal Stability | High; up to 400degC | Moderate; up to 230degC |

| Mechanical Strength | Excellent tensile and abrasion resistance | Good tensile strength, less abrasion resistant |

| Chemical Resistance | Superior resistance to solvents and chemicals | Moderate resistance; susceptible to hydrolysis |

| Applications | Electronics, aerospace, flexible circuits | Textiles, automotive parts, packaging |

| Cost | Higher due to complex synthesis | Lower, widely produced |

| Flexibility | Good flexibility, retains properties at high temperatures | Moderate flexibility, decreases at high temperatures |

| Moisture Absorption | Low moisture absorption | Higher moisture absorption |

Polyimide vs Polyamide: An Overview

Polyimide exhibits superior thermal stability and chemical resistance compared to polyamide, making it ideal for high-performance applications in aerospace and electronics. Polyamide, commonly known as Nylon, offers excellent mechanical strength and flexibility but lacks the high-temperature endurance of polyimide. The choice between polyimide and polyamide depends on specific requirements such as operating temperature, chemical exposure, and mechanical properties.

Chemical Structure Differences

Polyimides contain imide groups characterized by two acyl groups bonded to a nitrogen atom, forming a highly thermally stable and rigid ring structure. Polyamides consist of amide linkages featuring a carbonyl group bonded to a nitrogen atom, resulting in more flexible chains with hydrogen bonding capabilities. The imide functionality in polyimides imparts superior thermal resistance compared to the amide groups in polyamides.

Mechanical Properties Comparison

Polyimides exhibit superior mechanical properties compared to polyamides, with higher tensile strength and enhanced thermal stability, making them ideal for high-performance applications. Polyimides maintain mechanical integrity at elevated temperatures above 300degC, whereas polyamides typically soften above 200degC. The rigidity and aromatic structure of polyimides contribute to greater stiffness and resistance to creep, outperforming the more flexible aliphatic chains found in polyamides.

Thermal Stability and Performance

Polyimide exhibits superior thermal stability compared to polyamide, maintaining structural integrity and mechanical properties at temperatures exceeding 400degC, whereas polyamide typically degrades above 200degC. The aromatic backbone of polyimides contributes to high heat resistance and dimensional stability, making them ideal for aerospace and electronics applications requiring prolonged exposure to extreme heat. Polyamides offer good mechanical strength and chemical resistance but fall short in high-temperature performance relative to polyimides, limiting their use in advanced thermal environments.

Chemical Resistance: Polyimide vs Polyamide

Polyimide exhibits superior chemical resistance compared to polyamide, maintaining stability against harsh solvents, acids, and bases at elevated temperatures. Polyamide tends to absorb moisture and degrade when exposed to strong acids and alkalis, limiting its chemical durability in aggressive environments. Consequently, polyimide is preferred for applications requiring long-term resistance to chemical corrosion and thermal stress.

Electrical Insulation Capabilities

Polyimide exhibits superior electrical insulation properties compared to polyamide, with high dielectric strength typically around 300-500 kV/mm and excellent thermal stability up to 400degC, making it ideal for advanced aerospace and electronics applications. Polyamide offers moderate electrical insulation with dielectric strengths in the range of 100-250 kV/mm but degrades more rapidly at elevated temperatures, limiting its use in high-performance insulating environments. The aromatic structure of polyimide contributes to less dielectric loss and enhanced resistance to electrical tracking, outperforming the aliphatic nature of polyamide in demanding electrical insulation roles.

Processing and Manufacturability

Polyimides offer superior thermal stability and chemical resistance compared to polyamides, allowing processing at higher temperatures without degradation. Polyamides, such as Nylon, are typically easier to process through conventional melt extrusion and injection molding due to their lower melting points and good flow properties. Polyimides require specialized processing techniques like solvent casting or high-temperature curing steps, which can increase manufacturing complexity and cost.

Common Applications in Industries

Polyimides are widely utilized in aerospace and electronics industries for their exceptional thermal stability and insulation properties, making them ideal for flexible printed circuit boards and high-temperature wire insulation. Polyamides, commonly known as nylons, dominate automotive and textile sectors due to their excellent mechanical strength, chemical resistance, and ease of processing for components such as gears, bearings, and durable fabrics. Both polymers serve critical roles in industrial applications where performance under mechanical stress and thermal conditions is essential.

Cost Analysis and Availability

Polyimide materials typically incur higher production costs due to complex synthesis and curing processes, whereas polyamides benefit from established manufacturing techniques that reduce expenses. Availability of polyamides is more widespread globally, supported by extensive supply chains and diverse applications in textiles and engineering plastics. Cost efficiency and easier procurement make polyamides preferable for large-scale, budget-sensitive projects compared to polyimides, which are reserved for high-performance, specialized uses.

Environmental Impact and Sustainability

Polyimide exhibits superior thermal stability and chemical resistance, resulting in longer product lifecycles and reduced waste generation compared to polyamide. Polyamide, derived primarily from petroleum-based sources, often involves more energy-intensive production processes and higher greenhouse gas emissions. Recycling options for polyimides remain limited, but advancements in chemical recycling are making both polymers increasingly sustainable.

Polyimide vs Polyamide Infographic

materialdif.com

materialdif.com