Monomer conversion is a critical factor in polymerization efficiency, determining the percentage of monomers transformed into polymer chains. Chain transfer affects polymer molecular weight by transferring the active center from one polymer chain to another, thereby limiting chain growth. Balancing high monomer conversion with controlled chain transfer reactions is essential for optimizing polymer properties and performance.

Table of Comparison

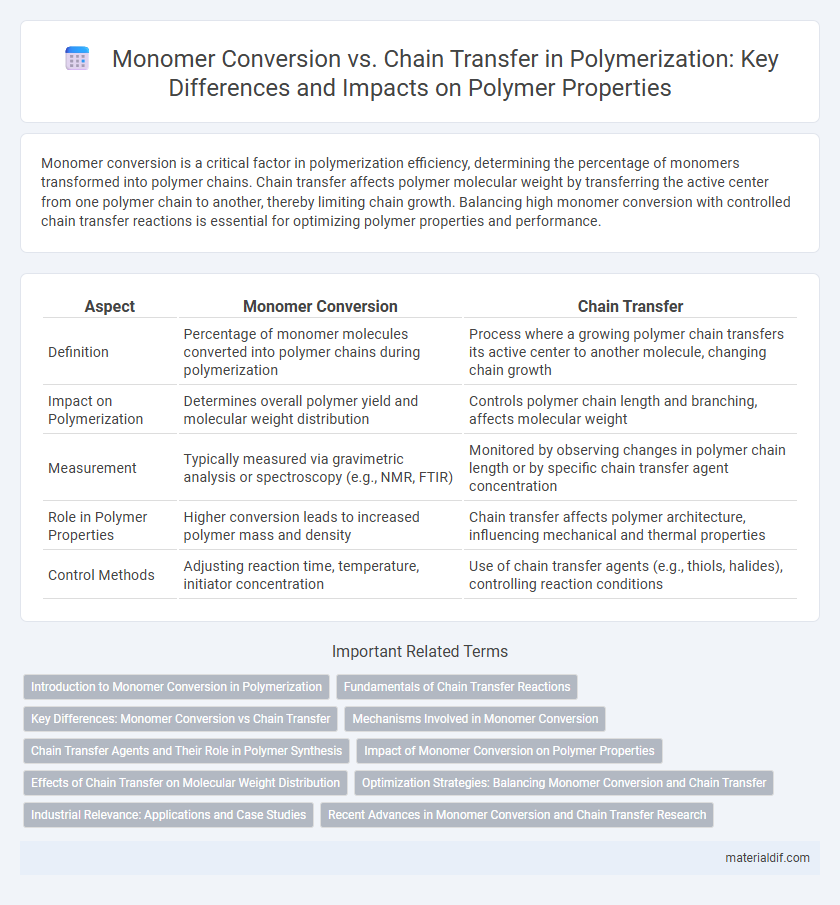

| Aspect | Monomer Conversion | Chain Transfer |

|---|---|---|

| Definition | Percentage of monomer molecules converted into polymer chains during polymerization | Process where a growing polymer chain transfers its active center to another molecule, changing chain growth |

| Impact on Polymerization | Determines overall polymer yield and molecular weight distribution | Controls polymer chain length and branching, affects molecular weight |

| Measurement | Typically measured via gravimetric analysis or spectroscopy (e.g., NMR, FTIR) | Monitored by observing changes in polymer chain length or by specific chain transfer agent concentration |

| Role in Polymer Properties | Higher conversion leads to increased polymer mass and density | Chain transfer affects polymer architecture, influencing mechanical and thermal properties |

| Control Methods | Adjusting reaction time, temperature, initiator concentration | Use of chain transfer agents (e.g., thiols, halides), controlling reaction conditions |

Introduction to Monomer Conversion in Polymerization

Monomer conversion in polymerization measures the percentage of monomer molecules transformed into polymer chains, directly impacting polymer yield and molecular weight distribution. Chain transfer reactions influence monomer conversion by limiting polymer chain growth, thereby controlling polymer architecture and properties. Understanding the balance between monomer conversion rates and chain transfer mechanisms is essential for optimizing polymer synthesis and achieving desired material characteristics.

Fundamentals of Chain Transfer Reactions

Chain transfer reactions in polymerization control molecular weight by transferring the active center from a growing polymer chain to another molecule, often a monomer or solvent. High monomer conversion rates increase the likelihood of chain transfer events, leading to shorter polymer chains with lower molecular weight. Understanding the kinetics of chain transfer is essential for optimizing polymer properties and achieving desired molecular weight distributions.

Key Differences: Monomer Conversion vs Chain Transfer

Monomer conversion denotes the percentage of monomer units that have been polymerized into macromolecules, directly impacting the molecular weight and polymer yield. Chain transfer is a reaction mechanism where the growing polymer chain transfers its active center to another molecule, affecting polymer chain length and molecular weight distribution. The key difference lies in monomer conversion quantifying polymer formation, while chain transfer alters polymer architecture and controls polymer properties.

Mechanisms Involved in Monomer Conversion

Monomer conversion in polymerization primarily involves the initiation, propagation, and termination mechanisms, where reactive monomer units form growing polymer chains through free radical or ionic intermediates. Chain transfer competes with propagation by transferring the active center from a growing polymer chain to another molecule, effectively controlling molecular weight and polymer architecture. Understanding these mechanisms enables precise manipulation of polymer properties by modulating the balance between monomer conversion rates and chain transfer events.

Chain Transfer Agents and Their Role in Polymer Synthesis

Chain transfer agents (CTAs) significantly influence monomer conversion by regulating polymer chain growth during radical polymerization, effectively controlling molecular weight and polymer architecture. These agents act by transferring the active center from a growing polymer chain to a new molecule, thus terminating one chain and initiating another, which reduces polymerization rate but enhances structural uniformity. Selection of specific CTAs, such as thiols or halogenated compounds, tailors polymer properties by balancing chain transfer efficiency and monomer conversion rates in targeted polymer synthesis.

Impact of Monomer Conversion on Polymer Properties

High monomer conversion enhances polymer molecular weight but may increase chain transfer events, affecting polymer structure and performance. As monomer conversion rises, the polymer's thermal stability and mechanical strength generally improve due to longer polymer chains. However, excessive chain transfer during high conversion can lead to shorter chains, reducing tensile strength and altering polymer morphology.

Effects of Chain Transfer on Molecular Weight Distribution

Chain transfer reactions significantly influence molecular weight distribution by reducing the average polymer chain length through premature termination and formation of new radical sites. This process decreases monomer conversion efficiency as active centers shift, leading to broader molecular weight distribution and lower polymer molecular weights. Controlling chain transfer agents enables tailoring polymer properties by adjusting the balance between monomer conversion rate and molecular weight distribution.

Optimization Strategies: Balancing Monomer Conversion and Chain Transfer

Optimizing polymerization requires balancing high monomer conversion rates with controlled chain transfer to achieve desired polymer molecular weights and properties. Strategies include precise control of initiator concentration and reaction conditions to minimize premature chain transfer events while maximizing monomer utilization. Employing chain transfer agents selectively can regulate polymer architecture without severely compromising conversion efficiency.

Industrial Relevance: Applications and Case Studies

Monomer conversion efficiency critically influences the yield and cost-effectiveness of industrial polymer production, with chain transfer mechanisms directly impacting polymer molecular weight and product consistency. In high-density polyethylene manufacturing, controlling chain transfer agents ensures optimal balance between polymer properties and processing speed, enhancing applications in packaging and automotive components. Case studies in styrene polymerization demonstrate how precise modulation of chain transfer rates improves material toughness and thermal resistance, advancing performance in construction and consumer goods sectors.

Recent Advances in Monomer Conversion and Chain Transfer Research

Recent advances in monomer conversion have achieved higher efficiency and selectivity through the use of controlled radical polymerization techniques and novel catalysts. Breakthroughs in chain transfer mechanisms have enabled precise control over polymer molecular weight and architecture, improving material properties for industrial applications. State-of-the-art analytical methods such as real-time spectroscopy and chromatography now facilitate deeper understanding of kinetic parameters governing both monomer conversion and chain transfer processes.

Monomer Conversion vs Chain Transfer Infographic

materialdif.com

materialdif.com