Biodegradable polymers break down naturally through microbial activity, reducing environmental impact and promoting sustainability in packaging and medical applications. Non-biodegradable polymers, typically derived from petrochemicals, persist in the environment for decades, contributing to pollution and landfill accumulation. Choosing biodegradable polymers supports eco-friendly waste management and aligns with growing environmental regulations.

Table of Comparison

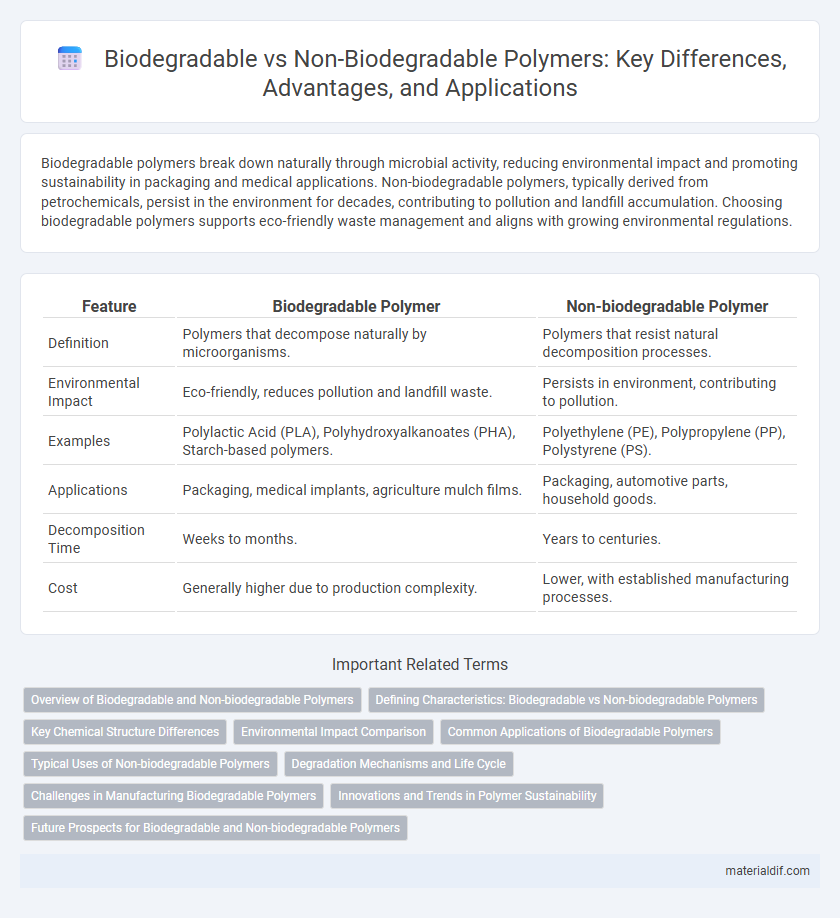

| Feature | Biodegradable Polymer | Non-biodegradable Polymer |

|---|---|---|

| Definition | Polymers that decompose naturally by microorganisms. | Polymers that resist natural decomposition processes. |

| Environmental Impact | Eco-friendly, reduces pollution and landfill waste. | Persists in environment, contributing to pollution. |

| Examples | Polylactic Acid (PLA), Polyhydroxyalkanoates (PHA), Starch-based polymers. | Polyethylene (PE), Polypropylene (PP), Polystyrene (PS). |

| Applications | Packaging, medical implants, agriculture mulch films. | Packaging, automotive parts, household goods. |

| Decomposition Time | Weeks to months. | Years to centuries. |

| Cost | Generally higher due to production complexity. | Lower, with established manufacturing processes. |

Overview of Biodegradable and Non-biodegradable Polymers

Biodegradable polymers such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA) decompose naturally through microbial activity, reducing environmental impact and waste accumulation. Non-biodegradable polymers like polyethylene (PE) and polypropylene (PP) persist in ecosystems for decades due to their chemical stability and resistance to microbial degradation. The distinction between these polymers is critical for sustainable material design and environmental management strategies in packaging, agriculture, and medical applications.

Defining Characteristics: Biodegradable vs Non-biodegradable Polymers

Biodegradable polymers are composed of macromolecules that microorganisms can break down into water, carbon dioxide, and biomass through enzymatic action, typically featuring natural or synthetic origins designed for environmental degradation. Non-biodegradable polymers consist of long-chain synthetic molecules resistant to microbial degradation, resulting in persistent environmental accumulation and long-term pollution. Key defining characteristics include chemical structure, molecular weight, and bond types influencing their susceptibility to degradation processes.

Key Chemical Structure Differences

Biodegradable polymers typically possess ester, amide, or ether linkages in their chemical structure, enabling enzymatic hydrolysis and microbial degradation. Non-biodegradable polymers often contain carbon-carbon backbone chains, such as polyethylene, that resist breakdown due to their stable covalent bonds. The presence of hydrolyzable functional groups in biodegradable polymers facilitates environmental decomposition, unlike the inert chemical bonds found in non-biodegradable counterparts.

Environmental Impact Comparison

Biodegradable polymers break down naturally through microbial activity, significantly reducing environmental pollution by minimizing plastic accumulation in landfills and oceans. Non-biodegradable polymers persist for centuries, leading to long-term ecological damage, including microplastic contamination and harm to wildlife. Lifecycle assessments reveal biodegradable polymers contribute less to carbon emissions and resource depletion, promoting a more sustainable and eco-friendly plastic alternative.

Common Applications of Biodegradable Polymers

Biodegradable polymers are widely used in medical applications such as sutures, drug delivery systems, and tissue engineering due to their ability to safely break down within the body. In agriculture, materials like polylactic acid (PLA) and polyhydroxyalkanoates (PHAs) serve as mulch films and controlled-release fertilizers that reduce environmental impact. Packaging industries utilize starch-based and cellulose-based biodegradable polymers to produce eco-friendly containers and bags, minimizing plastic waste in landfills.

Typical Uses of Non-biodegradable Polymers

Non-biodegradable polymers such as polyethylene, polypropylene, and polystyrene are widely used in packaging materials, automotive components, and construction due to their durability and resistance to environmental degradation. These polymers provide long-lasting performance in applications like plastic containers, pipes, and insulation materials essential for industrial and commercial sectors. Their resistance to microbial decomposition makes them ideal for products requiring extended lifespan and structural integrity.

Degradation Mechanisms and Life Cycle

Biodegradable polymers degrade through enzymatic hydrolysis or microbial assimilation, resulting in natural byproducts like water, carbon dioxide, and biomass, which significantly reduce environmental impact. Non-biodegradable polymers rely on physical processes such as photodegradation or thermal degradation, leading to fragmentation into persistent microplastics that accumulate in ecosystems. The life cycle of biodegradable polymers is typically shorter, with rapid environmental reintegration, whereas non-biodegradable polymers persist for decades or centuries, posing long-term pollution challenges.

Challenges in Manufacturing Biodegradable Polymers

Manufacturing biodegradable polymers faces significant challenges, including the high cost of raw materials like polylactic acid (PLA) and polyhydroxyalkanoates (PHA), which limits large-scale production. Controlling the polymerization process to achieve consistent mechanical properties and biodegradability is complex, requiring advanced catalysts and precise reaction conditions. Furthermore, issues with thermal stability and moisture sensitivity during processing hinder the integration of biodegradable polymers into existing manufacturing infrastructures.

Innovations and Trends in Polymer Sustainability

Biodegradable polymers, derived from renewable resources such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA), are advancing through innovations in enzymatic degradation and enhanced mechanical properties to address environmental concerns. Non-biodegradable polymers like polyethylene and polypropylene are seeing trends in chemical recycling technologies and the incorporation of bio-based additives to reduce carbon footprints. Sustainability in polymer science increasingly leverages lifecycle assessment tools and circular economy principles to optimize material performance and minimize ecological impact.

Future Prospects for Biodegradable and Non-biodegradable Polymers

Biodegradable polymers demonstrate significant future potential due to increasing environmental regulations and rising consumer demand for sustainable materials, particularly in packaging, agriculture, and medical applications. Advances in polymer chemistry are improving the mechanical properties and cost-effectiveness of biodegradable options, making them competitive alternatives to traditional non-biodegradable polymers. Despite this, non-biodegradable polymers will remain critical for applications requiring exceptional durability and resistance, driving ongoing innovation in recycling technologies and polymer modification to mitigate environmental impact.

Biodegradable Polymer vs Non-biodegradable Polymer Infographic

materialdif.com

materialdif.com