Amorphous polymers exhibit a random, disordered molecular structure that results in transparency and flexibility, while semi-crystalline polymers have ordered regions that contribute to higher density, strength, and resistance to chemical and thermal degradation. The degree of crystallinity influences mechanical properties, with semi-crystalline polymers offering better rigidity and thermal stability compared to their amorphous counterparts. Understanding the balance between amorphous and crystalline phases is crucial for tailoring polymer performance in applications such as packaging, automotive components, and medical devices.

Table of Comparison

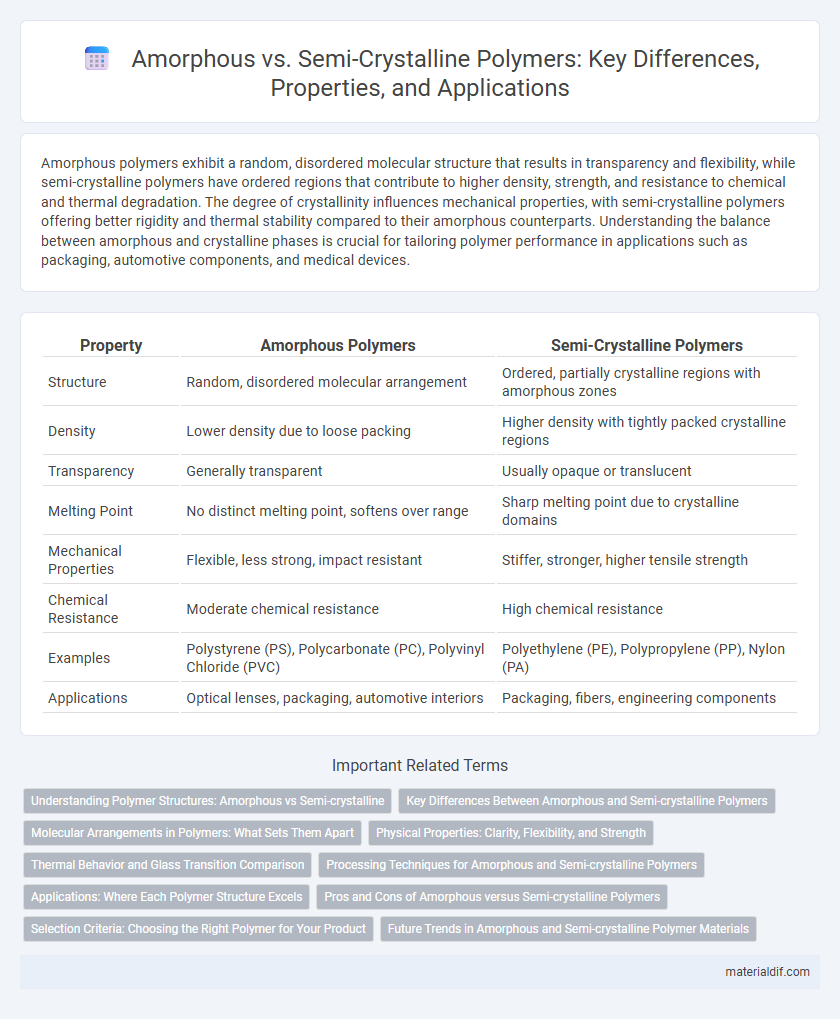

| Property | Amorphous Polymers | Semi-Crystalline Polymers |

|---|---|---|

| Structure | Random, disordered molecular arrangement | Ordered, partially crystalline regions with amorphous zones |

| Density | Lower density due to loose packing | Higher density with tightly packed crystalline regions |

| Transparency | Generally transparent | Usually opaque or translucent |

| Melting Point | No distinct melting point, softens over range | Sharp melting point due to crystalline domains |

| Mechanical Properties | Flexible, less strong, impact resistant | Stiffer, stronger, higher tensile strength |

| Chemical Resistance | Moderate chemical resistance | High chemical resistance |

| Examples | Polystyrene (PS), Polycarbonate (PC), Polyvinyl Chloride (PVC) | Polyethylene (PE), Polypropylene (PP), Nylon (PA) |

| Applications | Optical lenses, packaging, automotive interiors | Packaging, fibers, engineering components |

Understanding Polymer Structures: Amorphous vs Semi-crystalline

Amorphous polymers lack a defined order in their molecular chains, resulting in random, entangled structures that offer transparency and flexibility. Semi-crystalline polymers exhibit both ordered crystalline regions and disordered amorphous areas, providing enhanced mechanical strength and chemical resistance. Understanding the balance between amorphous and crystalline phases is crucial for tailoring polymer properties in applications such as packaging, automotive parts, and medical devices.

Key Differences Between Amorphous and Semi-crystalline Polymers

Amorphous polymers exhibit a random, disordered molecular arrangement leading to transparency and flexibility, while semi-crystalline polymers consist of both ordered crystalline regions and disordered amorphous regions, providing enhanced mechanical strength and thermal resistance. The degree of crystallinity influences properties such as density, melting temperature, and chemical resistance, with semi-crystalline polymers typically having higher density and melting points compared to amorphous counterparts. Key polymers such as polystyrene represent amorphous types, whereas polyethylene and polypropylene are common examples of semi-crystalline polymers.

Molecular Arrangements in Polymers: What Sets Them Apart

Amorphous polymers feature randomly arranged molecular chains, resulting in a disordered structure with no clear melting point, which imparts flexibility and transparency. Semi-crystalline polymers exhibit regions of highly ordered, tightly packed molecular chains interspersed with amorphous areas, giving rise to defined melting temperatures and increased mechanical strength. The distinct molecular arrangements between amorphous and semi-crystalline polymers significantly influence their thermal, optical, and mechanical properties.

Physical Properties: Clarity, Flexibility, and Strength

Amorphous polymers exhibit high clarity due to their random molecular arrangement, allowing light to pass through without scattering. Semi-crystalline polymers possess greater strength and chemical resistance because of their ordered, tightly packed molecular regions, but they tend to be less transparent. Flexibility varies as amorphous polymers are generally more flexible and impact-resistant, while semi-crystalline polymers offer increased rigidity and toughness.

Thermal Behavior and Glass Transition Comparison

Amorphous polymers exhibit a distinct glass transition temperature (Tg) where the material transitions from a rigid to a rubbery state, without a clear melting point due to the lack of crystalline regions. Semi-crystalline polymers display both a Tg and a melting temperature (Tm), with crystalline domains providing higher thermal stability and melting behavior. The thermal behavior of semi-crystalline polymers is characterized by a sharper transition at Tm and enhanced mechanical properties above Tg compared to amorphous polymers.

Processing Techniques for Amorphous and Semi-crystalline Polymers

Amorphous polymers, such as polystyrene and polycarbonate, require precise temperature control during processing techniques like injection molding and extrusion to avoid defects caused by their glass transition behavior. Semi-crystalline polymers, including polyethylene and polypropylene, benefit from controlled cooling rates in processes like blow molding and injection molding to promote optimal crystalline structure formation and enhance mechanical properties. Understanding the distinct thermal and rheological characteristics of these polymer types is essential for selecting appropriate processing parameters and achieving desired product performance.

Applications: Where Each Polymer Structure Excels

Amorphous polymers excel in applications requiring transparency and impact resistance, such as optical lenses, packaging films, and medical devices due to their random molecular arrangement and inherent flexibility. Semi-crystalline polymers are ideal for high-strength applications like automotive parts, fibers, and containers, benefiting from their ordered molecular regions that provide enhanced chemical resistance and mechanical durability. The choice between these structures depends on the balance of clarity, stiffness, thermal resistance, and chemical stability required by the specific application.

Pros and Cons of Amorphous versus Semi-crystalline Polymers

Amorphous polymers offer superior transparency and ease of processing due to their random molecular structure but typically exhibit lower chemical resistance and reduced mechanical strength compared to semi-crystalline polymers. Semi-crystalline polymers boast higher tensile strength, better chemical and thermal resistance, and increased wear resistance owing to their ordered molecular regions, yet they often have reduced clarity and are more challenging to process. Selecting between amorphous and semi-crystalline polymers depends on the application requirements for optical clarity, mechanical performance, and thermal stability.

Selection Criteria: Choosing the Right Polymer for Your Product

Selecting the right polymer for your product depends on the application's mechanical and thermal requirements. Amorphous polymers, such as polystyrene and polycarbonate, offer transparency, good impact resistance, and easier processing due to their random molecular arrangement. Semi-crystalline polymers like polyethylene and polypropylene provide higher chemical resistance, increased strength, and better dimensional stability owing to their ordered crystalline regions.

Future Trends in Amorphous and Semi-crystalline Polymer Materials

Future trends in amorphous and semi-crystalline polymer materials emphasize enhanced processing techniques such as advanced additive manufacturing and molecular orientation control to improve mechanical properties and thermal stability. Innovations in bio-based and recyclable polymers aim to balance crystallinity levels for optimal performance and sustainability. Emerging applications in flexible electronics and high-performance composites drive research toward tailored polymer crystallinity for specific functional requirements.

Amorphous vs Semi-crystalline Infographic

materialdif.com

materialdif.com