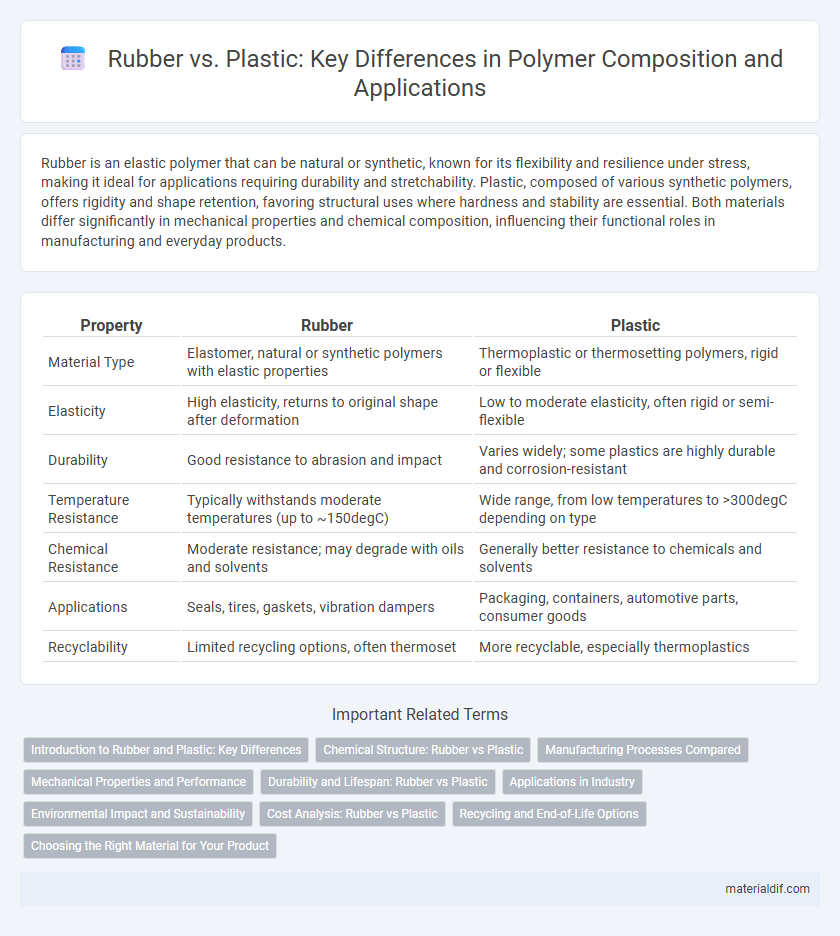

Rubber is an elastic polymer that can be natural or synthetic, known for its flexibility and resilience under stress, making it ideal for applications requiring durability and stretchability. Plastic, composed of various synthetic polymers, offers rigidity and shape retention, favoring structural uses where hardness and stability are essential. Both materials differ significantly in mechanical properties and chemical composition, influencing their functional roles in manufacturing and everyday products.

Table of Comparison

| Property | Rubber | Plastic |

|---|---|---|

| Material Type | Elastomer, natural or synthetic polymers with elastic properties | Thermoplastic or thermosetting polymers, rigid or flexible |

| Elasticity | High elasticity, returns to original shape after deformation | Low to moderate elasticity, often rigid or semi-flexible |

| Durability | Good resistance to abrasion and impact | Varies widely; some plastics are highly durable and corrosion-resistant |

| Temperature Resistance | Typically withstands moderate temperatures (up to ~150degC) | Wide range, from low temperatures to >300degC depending on type |

| Chemical Resistance | Moderate resistance; may degrade with oils and solvents | Generally better resistance to chemicals and solvents |

| Applications | Seals, tires, gaskets, vibration dampers | Packaging, containers, automotive parts, consumer goods |

| Recyclability | Limited recycling options, often thermoset | More recyclable, especially thermoplastics |

Introduction to Rubber and Plastic: Key Differences

Rubber is an elastic polymer known for its high flexibility and resilience, primarily derived from natural latex or synthetic sources like styrene-butadiene. Plastic refers to a broad category of polymers that are typically rigid or semi-rigid, formed from synthetic materials such as polyethylene or polypropylene. Key differences between rubber and plastic include elasticity, with rubber exhibiting significant stretchability, while plastic maintains structural rigidity under stress.

Chemical Structure: Rubber vs Plastic

Rubber consists primarily of long, cross-linked polymer chains made from isoprene units, giving it elastic and flexible properties due to its amorphous, lightly cross-linked structure. Plastic polymers, such as polyethylene or polystyrene, feature linear or branched chains with minimal cross-linking, resulting in rigid, moldable materials with higher crystallinity. The degree of cross-linking in rubber imparts elasticity, while thermoplastic plastics rely on chain entanglements and crystalline regions for strength and shape retention.

Manufacturing Processes Compared

Rubber manufacturing typically involves vulcanization, where heat and sulfur create cross-links between polymer chains, enhancing elasticity and durability, whereas plastic production often uses polymerization and molding techniques like injection molding or extrusion to shape thermoplastic or thermosetting polymers. Rubber processing demands precise temperature and pressure control to achieve the desired flexibility, while plastic manufacturing focuses on melting points and cooling rates to form rigid or semi-rigid products. Both materials require specialized equipment, but the chemical treatment in rubber manufacturing distinguishes it from the primarily physical shaping processes used for plastics.

Mechanical Properties and Performance

Rubber exhibits superior elasticity and resilience, enabling it to absorb impacts and return to its original shape without permanent deformation, which makes it ideal for applications requiring flexibility and shock absorption. Plastic, in contrast, generally offers higher tensile strength and rigidity, providing structural stability but less ability to withstand repetitive bending or stretching without cracking. The mechanical performance of rubber excels in dynamic, high-strain environments, while plastics are preferred where hardness, chemical resistance, and dimensional stability under load are critical.

Durability and Lifespan: Rubber vs Plastic

Rubber exhibits superior elasticity and resilience under repeated stress, contributing to a longer lifespan in applications requiring flexibility and impact resistance. Plastic, while often more resistant to chemical corrosion and less prone to environmental degradation, may suffer from brittleness and cracking over time depending on polymer composition. Durability assessments favor rubber for dynamic uses, whereas plastics excel in static load scenarios with exposure to harsh chemicals or UV radiation.

Applications in Industry

Rubber's elasticity and resilience make it essential in automotive tires, seals, and vibration dampening components, where flexibility and durability under stress are critical. Plastic's versatility and ease of molding enable widespread use in packaging, consumer goods, and electrical insulation, where lightweight and corrosion resistance are prioritized. Industrial applications leverage rubber for impact absorption and waterproofing, while plastics dominate in structural parts and chemical-resistant containers due to their rigid and customizable properties.

Environmental Impact and Sustainability

Rubber, especially natural rubber, presents a more sustainable option compared to most plastics due to its biodegradability and lower carbon footprint in production. Plastics, predominantly derived from fossil fuels, contribute significantly to environmental pollution and persist in ecosystems for hundreds of years, creating long-term waste management challenges. Innovations in recycling technologies and the development of bio-based plastics aim to reduce the environmental impact but have yet to match the ecological advantages of natural rubber.

Cost Analysis: Rubber vs Plastic

Rubber typically incurs higher raw material and processing costs compared to plastic due to its natural origin and vulcanization requirements, impacting overall production expenses. Plastic offers lower manufacturing costs and faster production cycles due to its synthetic composition and ease of molding, making it more cost-effective for large-scale applications. Maintenance and lifecycle costs also vary, with rubber providing better durability and elasticity in certain contexts, potentially offsetting higher upfront expenses over time.

Recycling and End-of-Life Options

Rubber recycling primarily involves processes like grinding and devulcanization to reclaim material for use in products such as mats and flooring, while plastics undergo mechanical, chemical, or energy recovery methods depending on polymer type. End-of-life options for rubber are limited by vulcanization, making it less biodegradable and more challenging to recycle compared to plastics, which have well-established recycling streams for polyethylene, polypropylene, and PET. Innovations in devulcanization and pyrolysis aim to improve rubber recyclability, whereas advances in sorting and reprocessing technologies enhance plastic recycling efficiency and reduce landfill dependency.

Choosing the Right Material for Your Product

Rubber offers superior elasticity and resilience, making it ideal for products requiring flexibility and impact resistance, while plastics provide diverse rigidity levels and excellent chemical resistance suited for structural applications. Consider factors such as mechanical stress, environmental exposure, and temperature range when selecting between rubber and plastic to ensure optimal performance and durability. Cost-effectiveness and manufacturing processes like injection molding or extrusion also influence the decision for material compatibility with your product design.

Rubber vs Plastic Infographic

materialdif.com

materialdif.com