Resin Transfer Molding (RTM) involves injecting resin into a closed mold cavity containing a fiber reinforcement, enabling precise control over fiber content and resulting in high-quality composite parts with excellent mechanical properties. Reaction Injection Molding (RIM) mixes reactive liquid components that polymerize and cure within the mold, producing lightweight and complex-shaped parts with fast cycle times and reduced tooling costs. RTM is preferred for structural applications requiring durability, while RIM suits large, intricate designs in automotive and aerospace industries.

Table of Comparison

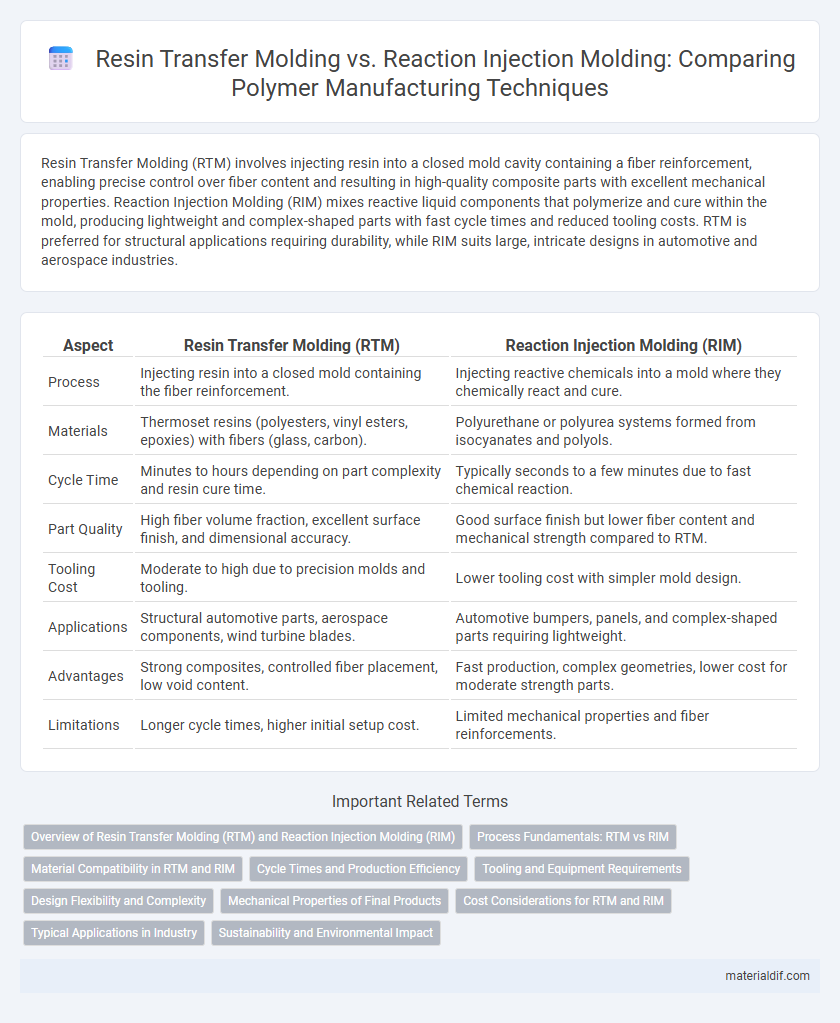

| Aspect | Resin Transfer Molding (RTM) | Reaction Injection Molding (RIM) |

|---|---|---|

| Process | Injecting resin into a closed mold containing the fiber reinforcement. | Injecting reactive chemicals into a mold where they chemically react and cure. |

| Materials | Thermoset resins (polyesters, vinyl esters, epoxies) with fibers (glass, carbon). | Polyurethane or polyurea systems formed from isocyanates and polyols. |

| Cycle Time | Minutes to hours depending on part complexity and resin cure time. | Typically seconds to a few minutes due to fast chemical reaction. |

| Part Quality | High fiber volume fraction, excellent surface finish, and dimensional accuracy. | Good surface finish but lower fiber content and mechanical strength compared to RTM. |

| Tooling Cost | Moderate to high due to precision molds and tooling. | Lower tooling cost with simpler mold design. |

| Applications | Structural automotive parts, aerospace components, wind turbine blades. | Automotive bumpers, panels, and complex-shaped parts requiring lightweight. |

| Advantages | Strong composites, controlled fiber placement, low void content. | Fast production, complex geometries, lower cost for moderate strength parts. |

| Limitations | Longer cycle times, higher initial setup cost. | Limited mechanical properties and fiber reinforcements. |

Overview of Resin Transfer Molding (RTM) and Reaction Injection Molding (RIM)

Resin Transfer Molding (RTM) involves injecting resin under pressure into a closed mold containing strategically placed fiber reinforcements, enabling the production of high-strength composite parts with excellent surface finish and dimensional accuracy. Reaction Injection Molding (RIM) mixes reactive liquid components, such as polyols and isocyanates, which react and cure rapidly within an open or closed mold, allowing for lightweight, large, and complex polyurethane parts with controlled density and mechanical properties. Both processes offer advantages in composite manufacturing, with RTM excelling in high-performance applications and RIM providing design flexibility and shorter cycle times.

Process Fundamentals: RTM vs RIM

Resin Transfer Molding (RTM) involves injecting resin under pressure into a closed mold containing a dry fiber preform, ensuring precise fiber alignment and minimal void content. Reaction Injection Molding (RIM) mixes two liquid monomers that rapidly polymerize within the mold, enabling low-pressure processing and short cycle times suitable for complex geometries. RTM typically achieves higher composite strength and surface finish quality, while RIM offers design flexibility and cost-effectiveness for large-volume production.

Material Compatibility in RTM and RIM

Resin Transfer Molding (RTM) excels in processing thermosetting resins such as epoxy, polyester, and vinyl ester, allowing for superior fiber wet-out and high mechanical performance composites. Reaction Injection Molding (RIM) is compatible with polyurethane and polyurea systems, offering fast cure times and the ability to mold large, complex parts with varying densities. Material compatibility in RTM supports high-strength, corrosion-resistant composites, while RIM provides versatility in elastomers and rigid polymers for automotive and industrial applications.

Cycle Times and Production Efficiency

Resin Transfer Molding (RTM) typically offers shorter cycle times due to the rapid injection and curing of low-viscosity resins, enhancing production efficiency for medium to high-volume composites. Reaction Injection Molding (RIM) involves slower curing of reactive monomers, resulting in longer cycle times but allowing for complex part geometries and lower tooling costs. Optimizing cycle times in RTM can lead to higher throughput, while RIM's efficiency benefits stem from its adaptability and reduced material waste.

Tooling and Equipment Requirements

Resin Transfer Molding (RTM) requires high-precision, rigid molds typically made from aluminum or steel to withstand injection pressure and ensure dimensional accuracy. Reaction Injection Molding (RIM) utilizes less expensive, often flexible tooling like silicone or polyurethane molds that accommodate lower pressure processes and faster cycle times. Equipment for RTM includes hydraulic presses and injection units for controlled resin flow, whereas RIM relies on low-pressure mixing and injection systems optimized for reactive polymer components.

Design Flexibility and Complexity

Resin Transfer Molding (RTM) offers higher design flexibility with the ability to produce complex, detailed parts including intricate fiber placements and varying thicknesses. Reaction Injection Molding (RIM) excels in rapidly creating large, lightweight components with less precise detail, suitable for simpler shapes and lower tooling costs. RTM is preferred for applications demanding structural strength and complex geometries, while RIM is ideal for high-volume, cost-sensitive parts with moderate complexity.

Mechanical Properties of Final Products

Resin Transfer Molding (RTM) typically produces composite parts with higher mechanical strength and better fiber volume fraction compared to Reaction Injection Molding (RIM), due to more precise control over resin impregnation and curing. RTM parts exhibit superior stiffness, impact resistance, and dimensional stability, making them ideal for structural applications. In contrast, RIM yields components with moderate mechanical properties but excels in producing complex geometries with faster cycle times and lower tooling costs.

Cost Considerations for RTM and RIM

Resin Transfer Molding (RTM) generally incurs higher tooling costs due to the need for durable, precision molds suited for high-pressure resin injection, making it more suitable for medium to high-volume production. Reaction Injection Molding (RIM) features lower tooling expenses with flexible molds and faster cycle times, offering cost advantages for lower volume or complex-shaped parts. Material costs in RTM are often higher because it uses preforms and specialized resins, whereas RIM uses liquid thermosetting polymers that cure rapidly, influencing overall manufacturing expenses.

Typical Applications in Industry

Resin Transfer Molding (RTM) is commonly used in aerospace and automotive industries for producing high-strength composite parts like aircraft panels and car body components due to its precision and surface finish. Reaction Injection Molding (RIM) is favored in automotive and furniture production for manufacturing large, complex polyurethane parts such as bumpers and foam cushions, offering lightweight and impact-resistant properties. Both methods address different industrial needs, with RTM excelling in high-performance composites and RIM suited for large, intricate polyurethane products.

Sustainability and Environmental Impact

Resin Transfer Molding (RTM) offers enhanced sustainability by enabling precise resin usage, reducing waste and energy consumption compared to traditional molding processes. Reaction Injection Molding (RIM) often involves higher emissions of volatile organic compounds (VOCs) due to rapid chemical reactions and use of isocyanates, raising environmental concerns. RTM's closed mold system improves worker safety and limits environmental pollutants, making it a more eco-friendly option in advanced polymer composite manufacturing.

Resin Transfer Molding vs Reaction Injection Molding Infographic

materialdif.com

materialdif.com