Additive manufacturing enables the production of complex polymer parts with intricate geometries that are difficult to achieve through traditional molding techniques. It offers rapid prototyping and customization without the need for expensive molds, reducing lead times and material waste. Traditional molding remains advantageous for high-volume production due to its efficiency and lower per-unit cost once the initial tooling is established.

Table of Comparison

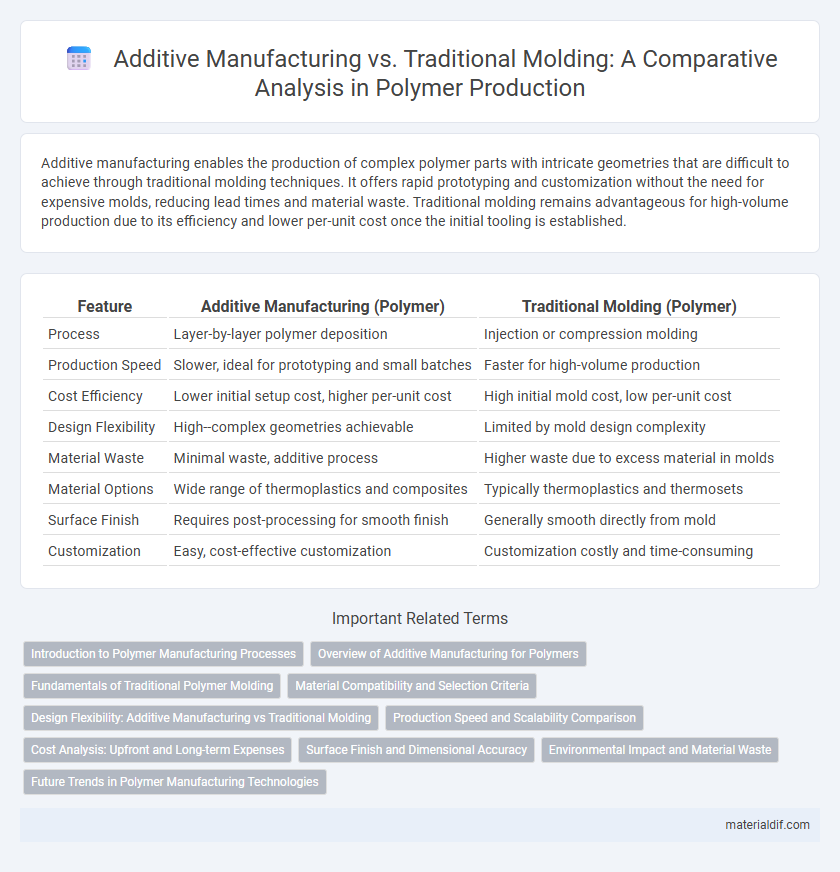

| Feature | Additive Manufacturing (Polymer) | Traditional Molding (Polymer) |

|---|---|---|

| Process | Layer-by-layer polymer deposition | Injection or compression molding |

| Production Speed | Slower, ideal for prototyping and small batches | Faster for high-volume production |

| Cost Efficiency | Lower initial setup cost, higher per-unit cost | High initial mold cost, low per-unit cost |

| Design Flexibility | High--complex geometries achievable | Limited by mold design complexity |

| Material Waste | Minimal waste, additive process | Higher waste due to excess material in molds |

| Material Options | Wide range of thermoplastics and composites | Typically thermoplastics and thermosets |

| Surface Finish | Requires post-processing for smooth finish | Generally smooth directly from mold |

| Customization | Easy, cost-effective customization | Customization costly and time-consuming |

Introduction to Polymer Manufacturing Processes

Additive manufacturing enables the layer-by-layer construction of complex polymer parts with precise control over geometry, reducing material waste compared to traditional molding techniques. Traditional molding processes such as injection molding rely on high-pressure injection of molten polymer into metal molds, offering rapid production rates ideal for large-volume runs. Polymer manufacturing processes must consider factors like polymer type, part complexity, and production scale to select between additive manufacturing and conventional molding for optimal efficiency and mechanical performance.

Overview of Additive Manufacturing for Polymers

Additive manufacturing for polymers employs layer-by-layer fabrication techniques such as Fused Deposition Modeling (FDM) and Stereolithography (SLA), enabling complex geometries and rapid prototyping without the need for molds. This process enhances material efficiency and customization compared to traditional injection molding, which relies on rigid tooling and longer setup times. Advanced polymer materials used in additive manufacturing include thermoplastics like PLA, ABS, and high-performance resins optimized for mechanical strength and thermal resistance.

Fundamentals of Traditional Polymer Molding

Traditional polymer molding relies on processes such as injection molding, compression molding, and blow molding to shape polymers by applying heat and pressure within rigid molds. These methods ensure consistent replication of complex geometries and high-volume production with tight dimensional tolerances. Material properties such as viscosity, thermal stability, and curing kinetics critically influence the quality and performance of molded polymer components.

Material Compatibility and Selection Criteria

Additive manufacturing offers superior material compatibility by enabling the use of complex polymer blends and composites that are challenging for traditional molding processes. Selection criteria prioritize factors such as polymer viscosity, thermal stability, and mechanical properties, with additive techniques allowing for tailored material customization and reduced waste. Traditional molding favors polymers with predictable flow characteristics and high-volume production efficiency, while additive methods excel in low-volume, high-complexity applications requiring diverse material integration.

Design Flexibility: Additive Manufacturing vs Traditional Molding

Additive manufacturing offers superior design flexibility by enabling the creation of complex geometries and intricate internal structures that are difficult or impossible with traditional molding techniques. Traditional molding methods, such as injection molding, often require expensive and time-consuming tooling adjustments for design changes, limiting customization and rapid prototyping. The layer-by-layer build process of additive manufacturing facilitates rapid iterations and personalized polymer component production without the constraints of mold design.

Production Speed and Scalability Comparison

Additive manufacturing offers rapid prototyping with production speeds that excel in low to medium volume runs, enabling quick design iterations without the need for tooling changes. In contrast, traditional molding techniques, such as injection molding, provide faster cycle times and higher throughput for large-scale production once the initial mold is fabricated. Scalability is limited in additive manufacturing by build volume and print speed, whereas traditional molding supports mass production with consistent part quality and economies of scale.

Cost Analysis: Upfront and Long-term Expenses

Additive manufacturing in polymer production often requires lower upfront investment due to reduced tooling costs compared to traditional molding processes, which typically involve expensive molds and longer setup times. Over the long term, additive manufacturing can lead to cost savings through minimal material waste and the ability to produce complex geometries without additional expenses, whereas traditional molding benefits from economies of scale in large production runs. Cost analysis reveals that while traditional molding is more cost-effective for high-volume manufacturing, additive manufacturing offers financial advantages for prototyping, customization, and low-to-medium volume production.

Surface Finish and Dimensional Accuracy

Additive manufacturing of polymers enables complex geometries with customizable surface textures but often results in layer lines and lower surface smoothness compared to traditional molding methods. Traditional molding, such as injection molding, delivers superior dimensional accuracy and consistent smooth surface finishes due to controlled cooling and high-pressure injection. Surface finish optimization in additive manufacturing requires post-processing techniques, whereas traditional molding inherently achieves high precision and smoother polymer surfaces directly from the mold.

Environmental Impact and Material Waste

Additive manufacturing in polymer production significantly reduces material waste by building components layer-by-layer, using only the necessary amount of polymer compared to traditional molding, which often involves excess trim and sprue waste. The environmental impact is lowered in additive processes due to minimized energy consumption and decreased emissions from reduced material handling and post-processing steps. Traditional molding methods typically require higher energy input for heating large molds and generate more scrap, leading to greater landfill contributions and resource depletion.

Future Trends in Polymer Manufacturing Technologies

Additive manufacturing in polymer production enables complex geometries, design flexibility, and rapid prototyping unmatched by traditional molding techniques. Emerging trends emphasize biopolymers, multi-material printing, and AI-driven process optimization to enhance sustainability and precision. The shift towards smart polymers integrated with sensors and IoT compatibility is set to transform future manufacturing landscapes.

Additive Manufacturing vs Traditional Molding Infographic

materialdif.com

materialdif.com