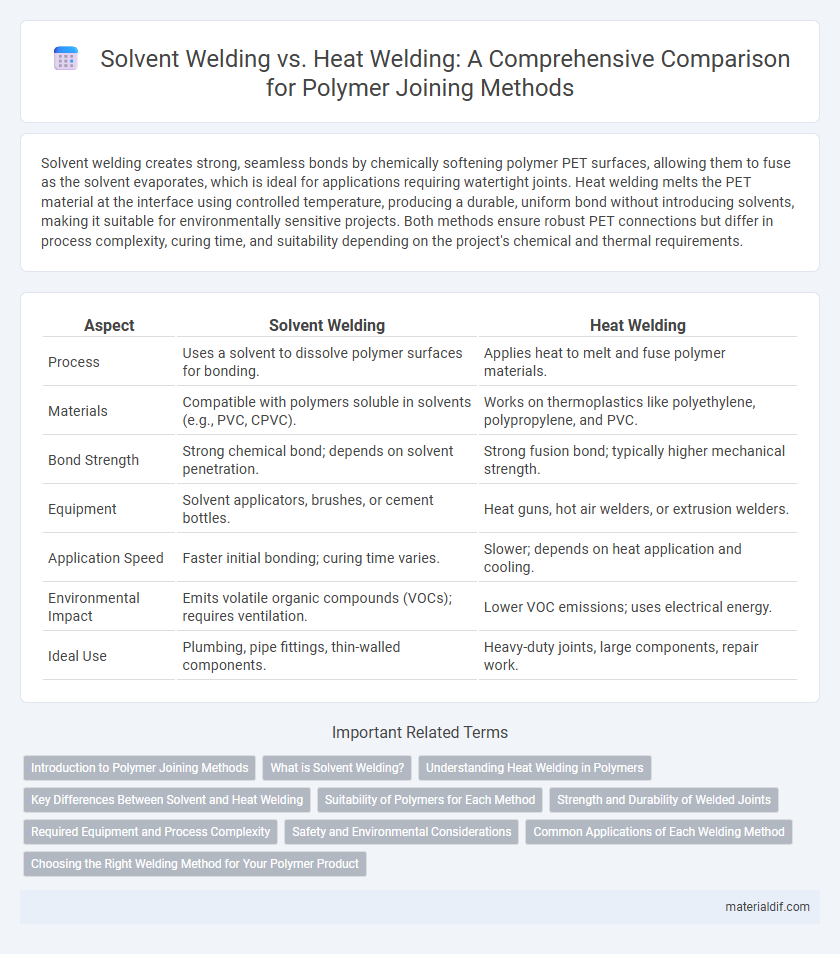

Solvent welding creates strong, seamless bonds by chemically softening polymer PET surfaces, allowing them to fuse as the solvent evaporates, which is ideal for applications requiring watertight joints. Heat welding melts the PET material at the interface using controlled temperature, producing a durable, uniform bond without introducing solvents, making it suitable for environmentally sensitive projects. Both methods ensure robust PET connections but differ in process complexity, curing time, and suitability depending on the project's chemical and thermal requirements.

Table of Comparison

| Aspect | Solvent Welding | Heat Welding |

|---|---|---|

| Process | Uses a solvent to dissolve polymer surfaces for bonding. | Applies heat to melt and fuse polymer materials. |

| Materials | Compatible with polymers soluble in solvents (e.g., PVC, CPVC). | Works on thermoplastics like polyethylene, polypropylene, and PVC. |

| Bond Strength | Strong chemical bond; depends on solvent penetration. | Strong fusion bond; typically higher mechanical strength. |

| Equipment | Solvent applicators, brushes, or cement bottles. | Heat guns, hot air welders, or extrusion welders. |

| Application Speed | Faster initial bonding; curing time varies. | Slower; depends on heat application and cooling. |

| Environmental Impact | Emits volatile organic compounds (VOCs); requires ventilation. | Lower VOC emissions; uses electrical energy. |

| Ideal Use | Plumbing, pipe fittings, thin-walled components. | Heavy-duty joints, large components, repair work. |

Introduction to Polymer Joining Methods

Solvent welding involves using a chemical solvent to soften polymer surfaces, allowing them to fuse upon contact, creating strong, seamless joints ideal for thermoplastics like PVC and acrylic. Heat welding applies controlled heat to melt the polymer edges, which then bond as they cool, commonly used in materials such as polyethylene and polypropylene to achieve durable, pressure-resistant connections. Both methods play crucial roles in polymer joining, with solvent welding favored for precision and clean bonds, while heat welding offers robust structural integrity for thicker or industrial-grade plastics.

What is Solvent Welding?

Solvent welding is a polymer joining technique that uses a chemical solvent to dissolve the surface of plastic materials, allowing them to fuse together at the molecular level as the solvent evaporates. This process is commonly applied to thermoplastics such as PVC, ABS, and acrylic, providing strong, airtight, and watertight bonds without the need for high heat. Solvent welding offers precise control and minimal distortion, making it ideal for applications in piping, automotive components, and medical devices.

Understanding Heat Welding in Polymers

Heat welding in polymers involves using controlled heat to soften the material at the joint interface, allowing molecular chains to fuse together upon cooling. This method creates a strong, homogeneous bond ideal for thermoplastics such as polyethylene, polypropylene, and PVC. Heat welding offers superior mechanical strength and environmental resistance compared to solvent welding, which relies on chemical solvents to dissolve and join surfaces.

Key Differences Between Solvent and Heat Welding

Solvent welding creates a chemical bond by dissolving polymer surfaces with a solvent, allowing the materials to fuse as the solvent evaporates, whereas heat welding uses thermal energy to melt and join polymers physically. Solvent welding is typically used for plastics like PVC and ABS, providing seamless joints with minimal distortion, while heat welding is preferred for thermoplastics like polyethylene and polypropylene, producing strong mechanical bonds through melting. The key differences include the bonding mechanism--chemical versus physical--application methods, and suitable polymer types, influencing strength, appearance, and curing time.

Suitability of Polymers for Each Method

Solvent welding is most suitable for polymers such as PVC, ABS, and acrylics that dissolve slightly in specific solvents, enabling strong chemical bonds without heat. Heat welding works best with thermoplastics like polyethylene, polypropylene, and polycarbonate, which soften upon heating and fuse upon cooling to form durable joints. Polymers with low thermal resistance or chemical inertness are less compatible with these methods, requiring alternative joining techniques.

Strength and Durability of Welded Joints

Solvent welding creates strong, durable joints by chemically dissolving and fusing polymer surfaces, resulting in a seamless bond ideal for PVC and acrylic materials. Heat welding relies on melting the polymer at the joint interface, producing robust welds with high tensile strength, commonly used for polyethylene and polypropylene. Both methods yield long-lasting connections, but solvent welding offers superior chemical resistance while heat welding provides enhanced mechanical strength in demanding applications.

Required Equipment and Process Complexity

Solvent welding requires chemical solvents and applicators to dissolve polymer surfaces for bonding, demanding precise handling and ventilation equipment to ensure safety. Heat welding involves specialized hot air guns or ultrasonic welding machines that melt polymer surfaces, requiring skilled operators to control temperature and pressure for effective joints. The process complexity of solvent welding centers on chemical exposure and curing time, whereas heat welding demands equipment calibration and operator expertise to prevent material degradation.

Safety and Environmental Considerations

Solvent welding involves the use of chemical solvents that can emit volatile organic compounds (VOCs), posing health risks such as respiratory issues and environmental concerns due to solvent toxicity and flammability. Heat welding eliminates the need for solvents, reducing exposure to harmful fumes and lowering environmental impact by avoiding solvent disposal, but it requires careful temperature control to prevent burns and material degradation. Both methods demand appropriate safety measures, including proper ventilation, personal protective equipment, and adherence to environmental regulations to minimize health hazards and ecological footprint.

Common Applications of Each Welding Method

Solvent welding is commonly used for joining PVC pipes and fittings in plumbing and irrigation systems due to its ability to create strong, leak-proof bonds without melting the material. Heat welding is frequently applied in the fabrication of polyethylene tanks, geomembranes, and roofing membranes where high-strength, durable joints are critical under mechanical stress. Both welding methods are essential in industrial manufacturing and construction, selecting the technique based on polymer type, application requirements, and environmental conditions.

Choosing the Right Welding Method for Your Polymer Product

Solvent welding is ideal for polymers like PVC and ABS where chemical bonding creates a strong, leak-proof joint by softening the surface with a solvent. Heat welding suits thermoplastics such as polyethylene and polypropylene, employing controlled heat to melt and fuse materials without introducing chemicals. Selecting the right method depends on polymer type, application requirements, joint strength, and environmental exposure to ensure durability and performance.

Solvent Welding vs Heat Welding Infographic

materialdif.com

materialdif.com