Extrusion involves forcing molten polymer through a shaped die to create continuous profiles with consistent cross-sections, ideal for producing pipes, films, and sheets. Rotomolding, or rotational molding, distributes polymer powder inside a heated mold that rotates on multiple axes, enabling the creation of hollow, seamless, and complex-shaped parts with uniform wall thickness. Each process offers unique advantages: extrusion excels in high-volume, uniform products, while rotomolding provides design flexibility for large, durable, and lightweight items.

Table of Comparison

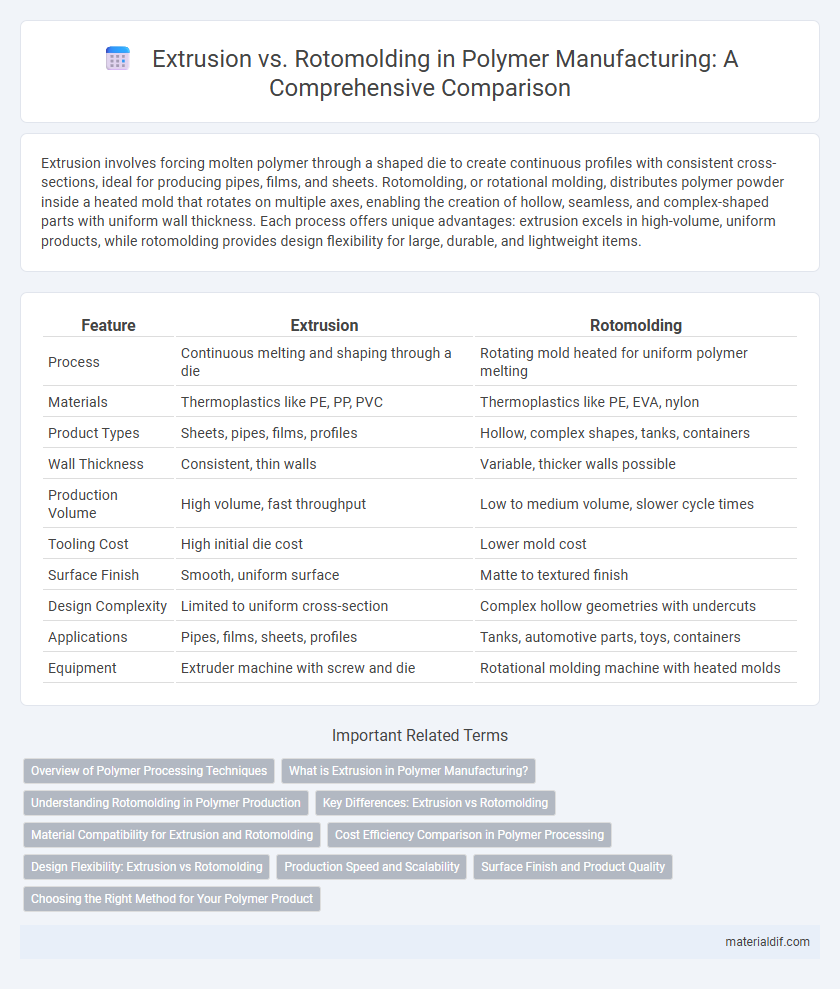

| Feature | Extrusion | Rotomolding |

|---|---|---|

| Process | Continuous melting and shaping through a die | Rotating mold heated for uniform polymer melting |

| Materials | Thermoplastics like PE, PP, PVC | Thermoplastics like PE, EVA, nylon |

| Product Types | Sheets, pipes, films, profiles | Hollow, complex shapes, tanks, containers |

| Wall Thickness | Consistent, thin walls | Variable, thicker walls possible |

| Production Volume | High volume, fast throughput | Low to medium volume, slower cycle times |

| Tooling Cost | High initial die cost | Lower mold cost |

| Surface Finish | Smooth, uniform surface | Matte to textured finish |

| Design Complexity | Limited to uniform cross-section | Complex hollow geometries with undercuts |

| Applications | Pipes, films, sheets, profiles | Tanks, automotive parts, toys, containers |

| Equipment | Extruder machine with screw and die | Rotational molding machine with heated molds |

Overview of Polymer Processing Techniques

Extrusion and rotomolding are prominent polymer processing techniques used to shape thermoplastics into functional products. Extrusion involves forcing molten polymer through a die to create continuous profiles such as pipes, sheets, or films, offering high production rates and consistent cross-sections. Rotomolding, or rotational molding, heats polymer powder inside a rotating mold, producing hollow, seamless objects with uniform wall thickness, ideal for complex shapes and low-stress parts.

What is Extrusion in Polymer Manufacturing?

Extrusion in polymer manufacturing is a continuous process where raw plastic material is melted and forced through a shaped die to create long products with a consistent cross-section, such as pipes, sheets, or films. This method allows precise control over product dimensions and is highly efficient for producing large volumes of uniform polymer profiles. Extrusion operates at high temperatures and pressures, optimizing polymer flow and material properties for applications in packaging, construction, and automotive industries.

Understanding Rotomolding in Polymer Production

Rotomolding in polymer production uses a heated mold that rotates on multiple axes, allowing the polymer to evenly coat the interior surfaces and form hollow, seamless parts. This process excels in producing large, complex shapes with uniform wall thickness and minimal stress, making it ideal for tanks, containers, and automotive components. Compared to extrusion, rotomolding offers greater design flexibility but typically has slower production rates and higher labor intensity.

Key Differences: Extrusion vs Rotomolding

Extrusion involves forcing heated polymer through a die to create continuous profiles with uniform cross-sections, ideal for pipes, sheets, and films, while rotomolding rotates a heated mold filled with polymer powder to form hollow, seamless objects such as tanks and containers. Extrusion offers high production speed and efficiency for consistent shapes, whereas rotomolding enables more complex, large, and hollow geometries with lower tooling costs but slower cycle times. Material selection differs, with extrusion commonly using thermoplastics like polyethylene and PVC, and rotomolding favoring polyethylene grades optimized for rotational molding processes.

Material Compatibility for Extrusion and Rotomolding

Extrusion processes are compatible with a wide range of thermoplastics such as polyethylene, polypropylene, and PVC, offering excellent control over material flow and enabling uniform cross-sectional profiles. Rotomolding primarily uses polyethylene and compatible polymers like cross-linkable nylons, benefiting from low processing temperatures that reduce material degradation and allow for intricate, hollow shapes. Material compatibility considerations dictate that extrusion suits materials requiring continuous shaping with precise dimensions, while rotomolding accommodates polymers with high molecular weight and thermal stability ideal for thick-walled, seamless products.

Cost Efficiency Comparison in Polymer Processing

Extrusion offers higher cost efficiency for large-scale polymer production due to faster cycle times and continuous operation, reducing labor and energy expenses. Rotomolding incurs higher initial equipment costs and longer cycle times but provides cost advantages in producing complex, hollow parts with lower material waste. Choosing between extrusion and rotomolding depends on production volume, part design complexity, and overall material utilization to optimize polymer processing costs.

Design Flexibility: Extrusion vs Rotomolding

Extrusion offers limited design flexibility due to its continuous profile shaping, making it ideal for uniform cross-sections but challenging for complex geometries. Rotomolding provides superior design flexibility, allowing the creation of intricate, hollow shapes with varying wall thicknesses and undercuts. This process supports customized, complex designs in applications such as large tanks, automotive components, and ergonomic containers.

Production Speed and Scalability

Extrusion offers high production speeds with continuous output, making it ideal for large-scale manufacturing and consistent product dimensions. Rotomolding, while slower due to its cycle-based process, excels in producing complex, hollow shapes with low tooling costs, but limits scalability for high-volume demands. Choosing between extrusion and rotomolding depends on balancing fast throughput requirements against the need for intricate designs and production flexibility.

Surface Finish and Product Quality

Extrusion produces polymer products with smooth, consistent surface finishes ideal for applications requiring high dimensional accuracy and fine detail. Rotomolding typically results in thicker, less uniform surfaces with potential for seams or slight imperfections, suited for larger, hollow items where structural integrity outweighs surface precision. The choice between extrusion and rotomolding impacts product quality significantly, with extrusion favoring high-quality, visually appealing surfaces and rotomolding delivering robust, durable parts.

Choosing the Right Method for Your Polymer Product

Extrusion offers continuous production ideal for uniform cross-sectional polymer products such as pipes, sheets, and films, delivering high efficiency and consistent quality. Rotomolding provides excellent design flexibility and produces hollow, complex shapes with uniform wall thickness, suitable for large, low-volume items like tanks and containers. Selecting the right method depends on factors like product geometry, production volume, material properties, and cost-efficiency requirements.

Extrusion vs Rotomolding Infographic

materialdif.com

materialdif.com