Thermoplastic elastomers (TPEs) combine the elastic properties of rubber with the processing advantages of thermoplastics, allowing them to be melted and reshaped multiple times without significant degradation. Rubber, by contrast, is a cross-linked polymer that cannot be remolded after vulcanization, providing superior elasticity and resilience but limited recyclability. TPEs offer enhanced design flexibility and environmental benefits, making them ideal for applications requiring easy molding and recycling, while traditional rubber excels in durability and high-temperature resistance.

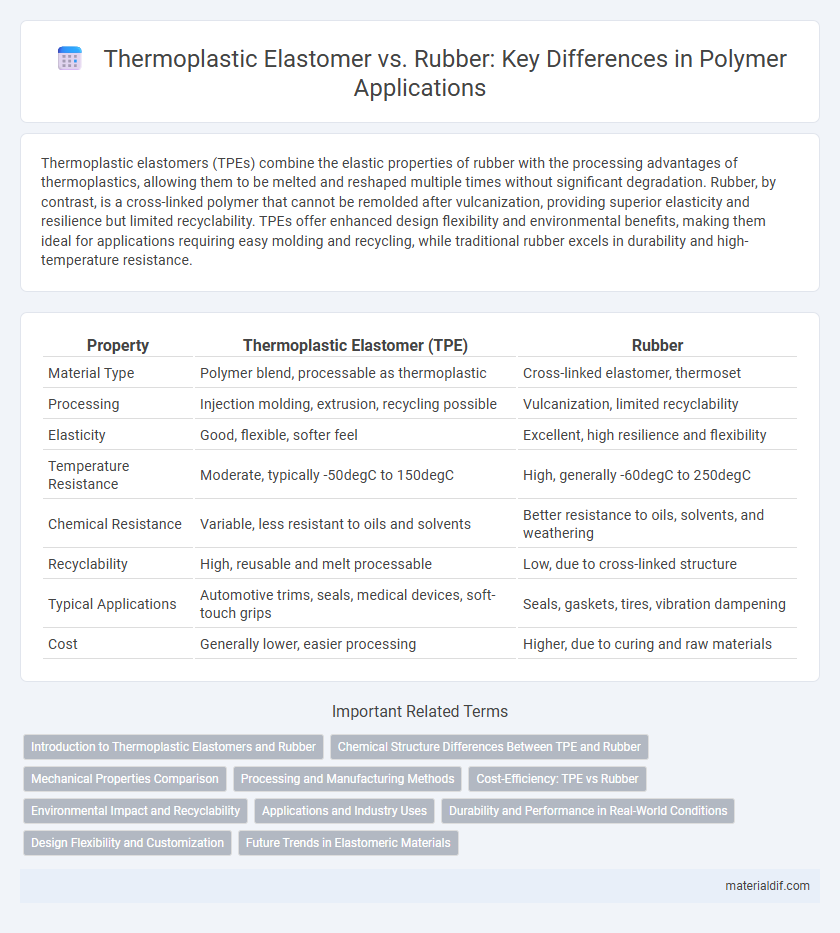

Table of Comparison

| Property | Thermoplastic Elastomer (TPE) | Rubber |

|---|---|---|

| Material Type | Polymer blend, processable as thermoplastic | Cross-linked elastomer, thermoset |

| Processing | Injection molding, extrusion, recycling possible | Vulcanization, limited recyclability |

| Elasticity | Good, flexible, softer feel | Excellent, high resilience and flexibility |

| Temperature Resistance | Moderate, typically -50degC to 150degC | High, generally -60degC to 250degC |

| Chemical Resistance | Variable, less resistant to oils and solvents | Better resistance to oils, solvents, and weathering |

| Recyclability | High, reusable and melt processable | Low, due to cross-linked structure |

| Typical Applications | Automotive trims, seals, medical devices, soft-touch grips | Seals, gaskets, tires, vibration dampening |

| Cost | Generally lower, easier processing | Higher, due to curing and raw materials |

Introduction to Thermoplastic Elastomers and Rubber

Thermoplastic elastomers (TPEs) combine the elastic properties of rubber with the processability of thermoplastics, enabling them to be reshaped and recycled without significant degradation. Unlike conventional rubber, which is typically crosslinked and vulcanized, TPEs consist of physically bonded block copolymers that provide flexibility and durability while allowing for easier manufacturing methods such as injection molding and extrusion. This unique composition makes TPEs valuable in automotive, medical, and consumer goods where both elasticity and recyclability are essential.

Chemical Structure Differences Between TPE and Rubber

Thermoplastic elastomers (TPE) consist of block copolymers with distinct hard and soft segments, characterized by thermoplastic blocks that provide reversible physical crosslinks, whereas rubber features a covalently crosslinked polymer network offering permanent elasticity. The chemical structure of TPE allows melting and reshaping without chemical degradation, contrasting with rubber's chemically vulcanized structure that prevents reprocessing. TPE's phase-separated morphology enables thermoplastic processing, while rubber's sulfur or peroxide crosslinks create durable, elastic properties that resist flow under heat.

Mechanical Properties Comparison

Thermoplastic elastomers (TPEs) exhibit superior elongation at break and higher tensile strength compared to conventional rubber, offering enhanced flexibility and durability. Unlike rubber, TPEs show improved resistance to wear, tear, and environmental stress cracking due to their thermoplastic nature and chemical structure. Their ability to be processed by injection molding or extrusion also allows for consistent mechanical performance and recyclability in diverse applications.

Processing and Manufacturing Methods

Thermoplastic elastomers (TPEs) offer greater versatility in processing due to their ability to be melted and reshaped repeatedly using methods such as injection molding, extrusion, and blow molding, which enhances manufacturing efficiency. In contrast, traditional rubber requires vulcanization, a chemical curing process involving heat and sulfur or peroxide crosslinkers, making its processing more time-consuming and less flexible. The reprocessability of TPEs reduces material waste and allows for faster production cycles compared to the irreversible curing steps in rubber manufacturing.

Cost-Efficiency: TPE vs Rubber

Thermoplastic elastomers (TPEs) offer superior cost-efficiency compared to rubber due to their ease of processing and recyclability, which reduces manufacturing and waste disposal expenses. TPEs eliminate the need for vulcanization, lowering energy consumption and production time, thereby cutting overall costs. Rubber materials often incur higher expenses related to processing complexity and limited recyclability, increasing long-term operational costs.

Environmental Impact and Recyclability

Thermoplastic elastomers (TPEs) offer superior environmental benefits compared to traditional rubber due to their enhanced recyclability and lower energy consumption during processing. Unlike vulcanized rubber, TPEs can be remelted and reshaped multiple times without significant degradation, reducing landfill waste and promoting circular economy practices. The reduced carbon footprint and easier end-of-life recycling of TPEs position them as a more sustainable choice in polymer applications.

Applications and Industry Uses

Thermoplastic elastomers (TPEs) offer versatile applications in automotive, medical, and consumer goods industries due to their recyclability and ease of processing compared to traditional rubber. Rubber remains preferred in heavy-duty applications like tires, seals, and vibration dampening where superior elasticity, heat resistance, and durability are critical. The ability of TPEs to combine elastomeric properties with thermoplastic processing makes them ideal for manufacturing flexible tubing, soft grips, and reusable packaging in diverse industrial uses.

Durability and Performance in Real-World Conditions

Thermoplastic elastomers (TPEs) offer superior durability compared to traditional rubber due to their resistance to wear, UV exposure, and chemical degradation in harsh environments. Their ability to maintain flexibility and tensile strength under fluctuating temperatures enhances performance in real-world applications like automotive seals and medical devices. Rubber, while elastic and resilient, often suffers from aging and cracking when exposed to prolonged heat and ozone, limiting its longevity in demanding conditions.

Design Flexibility and Customization

Thermoplastic elastomers (TPEs) offer superior design flexibility and customization compared to traditional rubber due to their ability to be melted and reshaped multiple times without losing properties. TPEs can be easily compounded with fillers, colorants, and modifiers to tailor mechanical properties and aesthetics for specific applications. Rubber, while durable and resilient, lacks the same processing versatility, limiting customization in complex or multi-material product designs.

Future Trends in Elastomeric Materials

Future trends in elastomeric materials emphasize sustainable thermoplastic elastomers (TPEs) due to their recyclability and ease of processing compared to traditional rubber. Advances in bio-based TPEs and nanocomposite integration enhance mechanical properties and environmental performance. Emerging applications in automotive, medical, and wearable technologies drive innovation towards customizable, high-performance elastomers with reduced carbon footprints.

Thermoplastic Elastomer vs Rubber Infographic

materialdif.com

materialdif.com