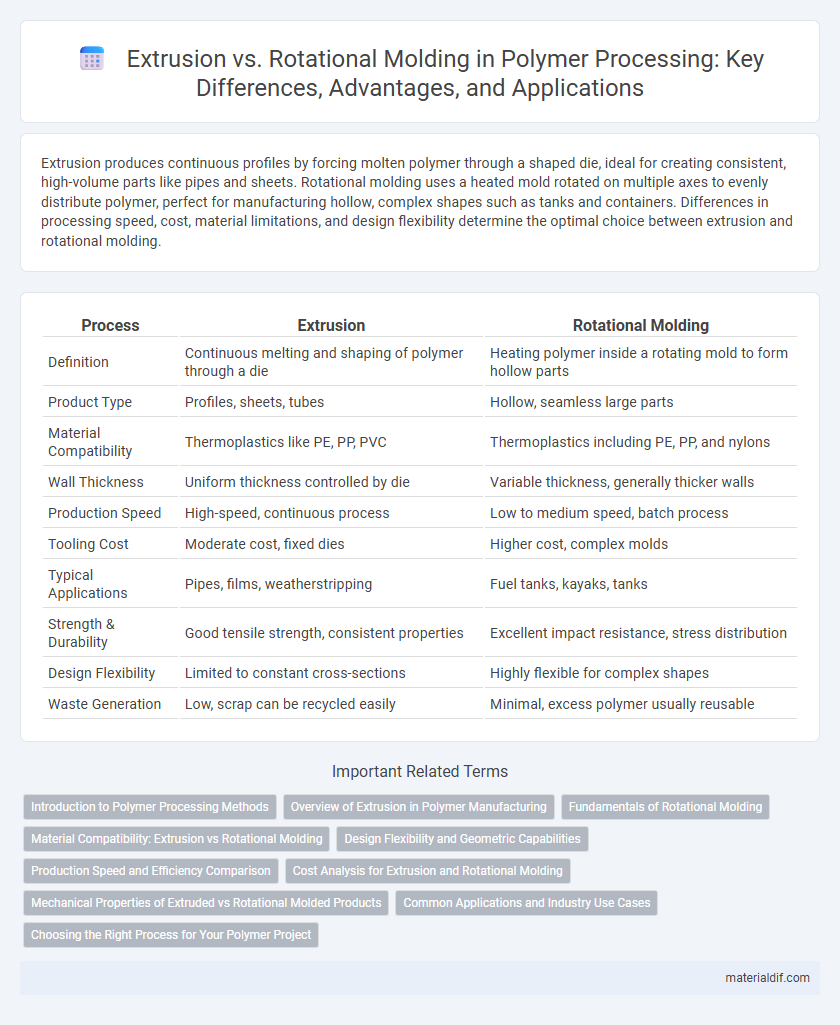

Extrusion produces continuous profiles by forcing molten polymer through a shaped die, ideal for creating consistent, high-volume parts like pipes and sheets. Rotational molding uses a heated mold rotated on multiple axes to evenly distribute polymer, perfect for manufacturing hollow, complex shapes such as tanks and containers. Differences in processing speed, cost, material limitations, and design flexibility determine the optimal choice between extrusion and rotational molding.

Table of Comparison

| Process | Extrusion | Rotational Molding |

|---|---|---|

| Definition | Continuous melting and shaping of polymer through a die | Heating polymer inside a rotating mold to form hollow parts |

| Product Type | Profiles, sheets, tubes | Hollow, seamless large parts |

| Material Compatibility | Thermoplastics like PE, PP, PVC | Thermoplastics including PE, PP, and nylons |

| Wall Thickness | Uniform thickness controlled by die | Variable thickness, generally thicker walls |

| Production Speed | High-speed, continuous process | Low to medium speed, batch process |

| Tooling Cost | Moderate cost, fixed dies | Higher cost, complex molds |

| Typical Applications | Pipes, films, weatherstripping | Fuel tanks, kayaks, tanks |

| Strength & Durability | Good tensile strength, consistent properties | Excellent impact resistance, stress distribution |

| Design Flexibility | Limited to constant cross-sections | Highly flexible for complex shapes |

| Waste Generation | Low, scrap can be recycled easily | Minimal, excess polymer usually reusable |

Introduction to Polymer Processing Methods

Extrusion and rotational molding are two fundamental polymer processing methods used to shape thermoplastic materials. Extrusion involves forcing molten polymer through a shaped die to create continuous profiles such as pipes, sheets, or films, offering high production rates and uniform cross-sections. Rotational molding, by contrast, uses a heated mold rotated along multiple axes to distribute polymer powder evenly, producing hollow, seamless products ideal for large, complex shapes with low internal stresses.

Overview of Extrusion in Polymer Manufacturing

Extrusion in polymer manufacturing involves forcing molten polymer through a shaped die to create continuous profiles such as pipes, sheets, and films, offering high production rates and uniform cross-sections. This process allows precise control over dimensions and material properties, making it suitable for thermoplastics like polyethylene, polypropylene, and PVC. Compared to rotational molding, extrusion excels in producing long lengths with consistent thickness, essential for applications in packaging, construction, and automotive industries.

Fundamentals of Rotational Molding

Rotational molding relies on heating powdered polymer in a mold that rotates biaxially, allowing the molten material to evenly coat the interior surface and form hollow, seamless parts. This process is ideal for producing large, complex, and hollow plastic products with uniform wall thickness, unlike extrusion which forces melted polymer through a die to create continuous profiles. The fundamental advantage of rotational molding lies in its ability to minimize internal stresses and eliminate weld lines, resulting in increased durability and design flexibility for polymers such as polyethylene and PVC.

Material Compatibility: Extrusion vs Rotational Molding

Extrusion processes excel with thermoplastics such as polyethylene, polypropylene, and PVC due to their ability to be continuously melted and shaped, ensuring consistent material properties and high throughput. Rotational molding accommodates a broader range of polymers, including polyethylene, polycarbonate, and some nylons, allowing for complex, hollow part designs but requires materials with low melt viscosity and good flow characteristics to fill molds evenly. Material compatibility for extrusion emphasizes flow stability and thermal resistance for continuous profiles, while rotational molding demands powders with specific melting points and sintering behavior to achieve uniform wall thickness.

Design Flexibility and Geometric Capabilities

Extrusion offers high design flexibility for continuous profiles, enabling complex cross-sectional shapes with consistent wall thickness ideal for pipes and sheets. Rotational molding excels in geometric capabilities for creating hollow, seamless, and large parts with uniform wall thickness, accommodating intricate three-dimensional shapes and undercuts. While extrusion is limited to linear geometries, rotational molding supports complex contours and varying wall thicknesses without stress concentrations, making it suitable for customized, volume-intensive polymer products.

Production Speed and Efficiency Comparison

Extrusion offers higher production speed and continuous output, making it ideal for large-volume polymer products with consistent cross-sections. Rotational molding operates at a slower pace due to its batch process, but it excels in producing complex, hollow shapes with minimal waste. Efficiency in extrusion is enhanced by automated processes, while rotational molding's efficiency lies in reduced tooling costs and flexibility for low to medium production runs.

Cost Analysis for Extrusion and Rotational Molding

Extrusion generally offers lower production costs due to continuous processing and higher material efficiency, making it ideal for high-volume polymer products such as pipes and sheets. Rotational molding incurs higher setup and cycle times, which drive up costs, but it excels in producing large, hollow parts with complex geometries at lower tooling expenses compared to injection molding. Cost analysis reveals extrusion's advantage in economies of scale, while rotational molding remains cost-effective for low- to medium-volume runs with customized, large polymer components.

Mechanical Properties of Extruded vs Rotational Molded Products

Extruded polymer products exhibit superior mechanical properties such as higher tensile strength, stiffness, and impact resistance due to the molecular alignment induced by the extrusion process. Rotational molding typically produces products with lower density and reduced mechanical strength, as the polymer particles fuse without significant shear or orientation. These differences make extrusion ideal for applications requiring robust structural performance, while rotational molding suits complex shapes with moderate mechanical demands.

Common Applications and Industry Use Cases

Extrusion is widely used in the production of pipes, sheets, and films due to its continuous manufacturing process suited for generating long, uniform profiles in automotive and construction industries. Rotational molding is preferred for creating hollow, seamless products such as tanks, containers, and playground equipment, offering design flexibility and cost efficiency in low to medium volume production. Both methods serve critical roles in packaging, automotive parts, and consumer goods, with extrusion dominant in high-volume applications and rotational molding favored for complex, large, hollow components.

Choosing the Right Process for Your Polymer Project

Extrusion offers continuous production of uniform polymer profiles ideal for pipes, films, and sheets, providing high efficiency and cost-effectiveness for large-scale runs. Rotational molding excels in creating complex, hollow, and seamless products such as tanks and containers with excellent material distribution and minimal waste. Choosing the right polymer process depends on product geometry, production volume, and material properties to optimize performance and manufacturing costs.

Extrusion vs Rotational Molding Infographic

materialdif.com

materialdif.com