Cross-linked polymers consist of polymer chains interconnected through covalent bonds, creating a three-dimensional network that offers enhanced mechanical strength, thermal stability, and chemical resistance compared to linear polymers. Linear polymers have single, continuous chains that allow more flexibility and easier processing but typically result in lower durability and solvent resistance. The choice between cross-linked and linear polymers depends on the application requirements, balancing rigidity, elasticity, and resilience.

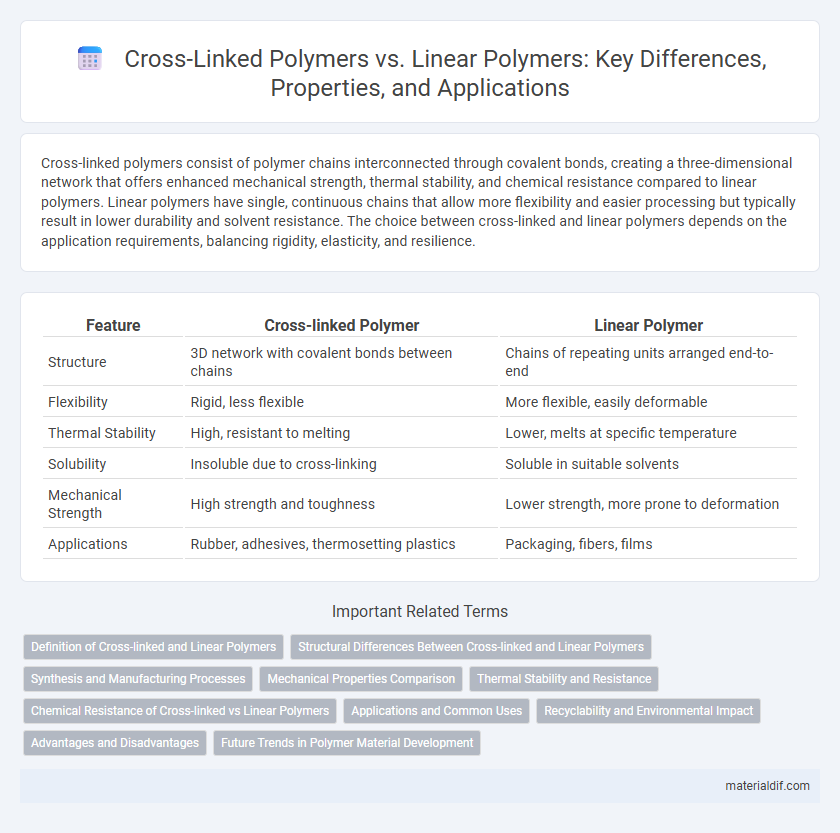

Table of Comparison

| Feature | Cross-linked Polymer | Linear Polymer |

|---|---|---|

| Structure | 3D network with covalent bonds between chains | Chains of repeating units arranged end-to-end |

| Flexibility | Rigid, less flexible | More flexible, easily deformable |

| Thermal Stability | High, resistant to melting | Lower, melts at specific temperature |

| Solubility | Insoluble due to cross-linking | Soluble in suitable solvents |

| Mechanical Strength | High strength and toughness | Lower strength, more prone to deformation |

| Applications | Rubber, adhesives, thermosetting plastics | Packaging, fibers, films |

Definition of Cross-linked and Linear Polymers

Cross-linked polymers consist of polymer chains interconnected by covalent bonds, forming a three-dimensional network that enhances their mechanical strength and thermal stability. Linear polymers are composed of long, continuous chains without branching or cross-linking, resulting in materials that are typically more flexible and easier to process. The degree of cross-linking significantly influences the polymer's rigidity, swelling behavior, and resistance to solvents.

Structural Differences Between Cross-linked and Linear Polymers

Cross-linked polymers consist of polymer chains interconnected through covalent bonds forming a three-dimensional network, enhancing their rigidity and thermal stability. Linear polymers are composed of repeating units connected in a single, continuous chain without such inter-chain links, resulting in greater flexibility and solubility. The structural differences significantly influence their mechanical properties, with cross-linked polymers exhibiting higher tensile strength and resistance to deformation compared to linear polymers.

Synthesis and Manufacturing Processes

Cross-linked polymers are synthesized through chemical reactions that form covalent bonds between polymer chains, often involving multifunctional monomers or crosslinking agents during polymerization, resulting in a three-dimensional network. Linear polymers are produced via chain-growth or step-growth polymerization processes that create long, unbranched chains without interchain bonds, making the manufacturing more straightforward and enabling easier melt processing. The choice of synthesis method directly influences the polymer's mechanical properties, thermal stability, and application suitability, with cross-linked polymers offering enhanced strength and chemical resistance compared to the flexible and processable linear counterparts.

Mechanical Properties Comparison

Cross-linked polymers exhibit superior mechanical strength and higher resistance to deformation compared to linear polymers due to their interconnected network structure. Linear polymers, characterized by individual polymer chains without cross-links, tend to have greater flexibility and elongation but lower tensile strength and thermal stability. The dense cross-linking in polymers enhances rigidity, dimensional stability, and resistance to solvents, making them ideal for applications demanding durability and structural integrity.

Thermal Stability and Resistance

Cross-linked polymers exhibit higher thermal stability compared to linear polymers due to their networked molecular structure, which restricts chain mobility and enhances resistance to heat-induced deformation. Linear polymers tend to have lower thermal resistance because their chains can move more freely, leading to earlier melting or softening under heat. The covalent bonds formed during cross-linking create a three-dimensional network that significantly improves the polymer's ability to maintain shape and mechanical properties at elevated temperatures.

Chemical Resistance of Cross-linked vs Linear Polymers

Cross-linked polymers exhibit superior chemical resistance compared to linear polymers due to their interconnected network structure, which restricts molecular mobility and reduces solvent penetration. The dense cross-linking enhances dimensional stability and resistance to swelling, making these polymers ideal for harsh chemical environments. In contrast, linear polymers with weaker intermolecular forces are more prone to chemical attack and degradation.

Applications and Common Uses

Cross-linked polymers are widely used in applications requiring high mechanical strength, thermal stability, and chemical resistance, such as in rubber tires, adhesives, and coatings. Linear polymers are commonly found in fibers, films, and plastics, with uses in textiles, packaging, and moldable materials due to their flexibility and ease of processing. Industrial sectors like automotive, construction, and packaging rely heavily on the specific properties of cross-linked and linear polymers to meet performance and durability standards.

Recyclability and Environmental Impact

Cross-linked polymers exhibit limited recyclability due to their rigid network structure, which resists melting and reshaping, leading to increased environmental persistence and waste accumulation. In contrast, linear polymers have thermoplastic properties that enable easier melting and reprocessing, enhancing their recyclability and reducing ecological footprint. The environmental impact of cross-linked polymers is intensified by their resistance to degradation, whereas linear polymers offer improved sustainability through more efficient recycling practices.

Advantages and Disadvantages

Cross-linked polymers exhibit superior thermal stability, chemical resistance, and mechanical strength compared to linear polymers, making them ideal for high-performance applications such as adhesives and coatings. However, their insolubility and infusibility limit recyclability and processability, contrasting with linear polymers that offer better melt flow and ease of fabrication but generally lower durability and mechanical robustness. The choice between cross-linked and linear polymers depends on balancing performance requirements against manufacturing flexibility and end-of-life considerations.

Future Trends in Polymer Material Development

Cross-linked polymers offer enhanced thermal stability, mechanical strength, and chemical resistance compared to linear polymers, making them ideal for advanced applications in aerospace and biomedicine. Future trends in polymer material development emphasize smart, stimuli-responsive cross-linked networks that enable self-healing and shape-memory properties. Innovations in sustainable cross-linking methods and recyclable polymer composites aim to address environmental challenges while maintaining performance.

Cross-linked Polymer vs Linear Polymer Infographic

materialdif.com

materialdif.com