Engineering polymers exhibit superior mechanical properties, thermal stability, and chemical resistance compared to commodity polymers, making them ideal for demanding applications in automotive, aerospace, and electronics industries. Commodity polymers are cost-effective and easier to process, commonly used in packaging, consumer goods, and household products where performance requirements are less stringent. Selecting between engineering and commodity polymers depends on balancing performance needs with budget constraints for the intended application.

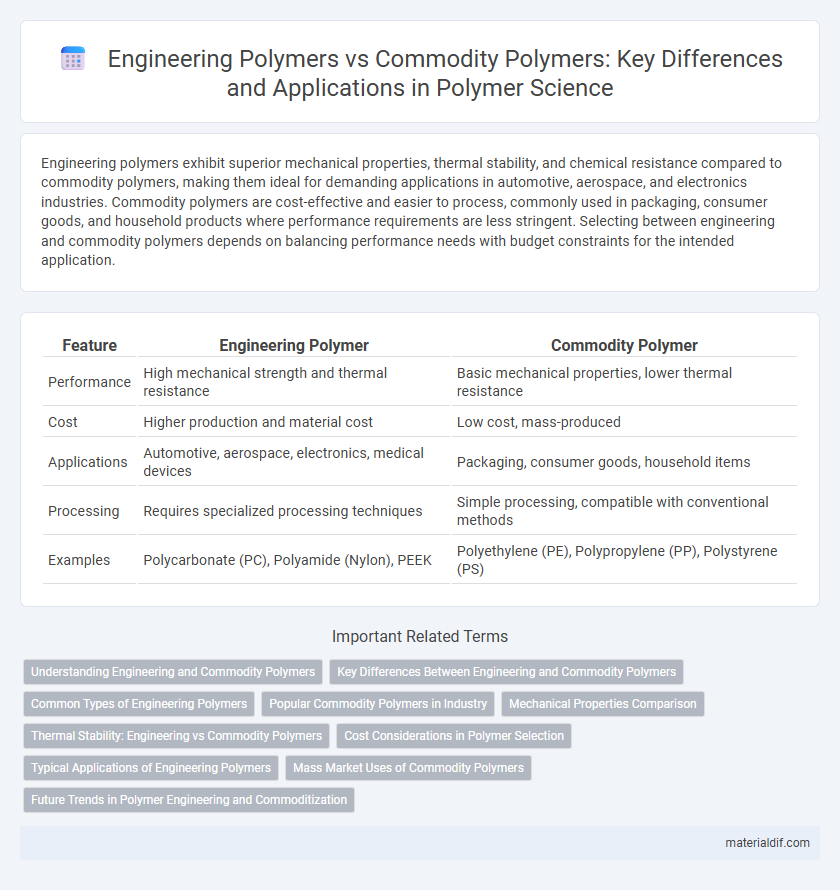

Table of Comparison

| Feature | Engineering Polymer | Commodity Polymer |

|---|---|---|

| Performance | High mechanical strength and thermal resistance | Basic mechanical properties, lower thermal resistance |

| Cost | Higher production and material cost | Low cost, mass-produced |

| Applications | Automotive, aerospace, electronics, medical devices | Packaging, consumer goods, household items |

| Processing | Requires specialized processing techniques | Simple processing, compatible with conventional methods |

| Examples | Polycarbonate (PC), Polyamide (Nylon), PEEK | Polyethylene (PE), Polypropylene (PP), Polystyrene (PS) |

Understanding Engineering and Commodity Polymers

Engineering polymers exhibit superior mechanical properties, thermal stability, and chemical resistance, making them ideal for high-performance applications in automotive, aerospace, and electronics industries. Commodity polymers, such as polyethylene and polypropylene, are produced in large volumes for everyday use, characterized by lower cost and simpler processing but limited performance properties. Understanding the distinct molecular structures and processing techniques of engineering versus commodity polymers aids in selecting the right material for specific industrial applications.

Key Differences Between Engineering and Commodity Polymers

Engineering polymers exhibit superior mechanical strength, thermal stability, and chemical resistance compared to commodity polymers, making them suitable for high-performance applications. Commodity polymers are primarily used for mass-produced, cost-sensitive items due to their lower production costs and simpler processing requirements. The key differences lie in their molecular structure complexity, performance characteristics, and end-use application demands.

Common Types of Engineering Polymers

Common types of engineering polymers include polycarbonate (PC), polyamide (nylon), polyoxymethylene (POM), and polyethylene terephthalate (PET), known for their superior mechanical strength, thermal stability, and chemical resistance compared to commodity polymers. These materials are widely used in automotive, aerospace, and electronics industries due to their durability and performance under demanding conditions. Engineering polymers offer enhanced properties such as higher tensile strength and impact resistance, distinguishing them from commodity polymers like polyethylene (PE) and polypropylene (PP), which prioritize cost-efficiency and ease of processing.

Popular Commodity Polymers in Industry

Popular commodity polymers in industry include polyethylene (PE), polypropylene (PP), polystyrene (PS), and polyvinyl chloride (PVC), known for their widespread use due to cost-effectiveness and versatile properties. These polymers are typically produced in high volumes for applications such as packaging, containers, and household goods, emphasizing economic efficiency over specialized performance. The balance between material properties and affordability makes commodity polymers foundational in mass-market manufacturing and construction sectors.

Mechanical Properties Comparison

Engineering polymers exhibit superior mechanical properties compared to commodity polymers, including higher tensile strength, enhanced impact resistance, and greater thermal stability. These polymers, such as polycarbonate and polyamide, are designed to withstand demanding mechanical stresses and maintain performance under elevated temperatures. Commodity polymers like polyethylene and polypropylene offer cost-effective solutions with moderate strength and flexibility but generally fall short in durability and mechanical robustness.

Thermal Stability: Engineering vs Commodity Polymers

Engineering polymers exhibit superior thermal stability compared to commodity polymers, often maintaining mechanical properties at temperatures exceeding 150degC, whereas commodity polymers typically degrade or soften around 100-120degC. Materials such as polycarbonate, polyamide, and polyphenylene sulfide are engineered for high-temperature applications, making them ideal for automotive, aerospace, and electrical components. Commodity polymers like polyethylene and polypropylene are favored for cost-effectiveness but lack the thermal resistance required for advanced engineering uses.

Cost Considerations in Polymer Selection

Engineering polymers typically exhibit superior mechanical properties and chemical resistance, justifying their higher cost in applications demanding durability and performance. Commodity polymers offer cost advantages due to large-scale production and simpler formulations, making them ideal for less critical, high-volume uses. Selecting between engineering and commodity polymers involves balancing budget constraints with the required material performance for the specific application.

Typical Applications of Engineering Polymers

Engineering polymers such as polycarbonate, nylon, and polyetheretherketone (PEEK) are extensively used in automotive parts, electrical components, and medical devices due to their superior mechanical strength, thermal stability, and chemical resistance. These polymers are preferred in applications requiring high performance under stress and exposure to harsh environments compared to commodity polymers like polyethylene and polypropylene. Typical applications include gears, bearings, electrical insulators, and structural components where durability and precision are critical.

Mass Market Uses of Commodity Polymers

Commodity polymers dominate the mass market due to their cost-effectiveness and versatility in everyday applications such as packaging, containers, and household goods. Their widespread use is driven by ease of processing, availability, and satisfactory performance for non-specialized roles. Engineering polymers, while offering superior mechanical and thermal properties, are less common in mass markets due to higher costs and complex processing requirements.

Future Trends in Polymer Engineering and Commoditization

Engineering polymers exhibit superior mechanical properties, thermal stability, and chemical resistance compared to commodity polymers, driving their adoption in high-performance applications such as automotive, aerospace, and electronics. Future trends reveal a growing emphasis on sustainable engineering polymers derived from bio-based or recycled materials, enhancing environmental compatibility without compromising functionality. The commoditization of polymers continues to expand through cost-effective production methods and broader application scopes, fueled by innovations in additive manufacturing and nanocomposite technologies.

Engineering Polymer vs Commodity Polymer Infographic

materialdif.com

materialdif.com