Biodegradable polymers offer an eco-friendly alternative to conventional polymers by breaking down naturally through microbial activity, reducing environmental pollution and landfill accumulation. These polymers are derived from renewable resources or designed with chemical structures that facilitate degradation, contrasting with conventional polymers made from petroleum-based monomers that persist for decades. Employing biodegradable polymers supports sustainable development by minimizing the ecological footprint associated with plastic waste.

Table of Comparison

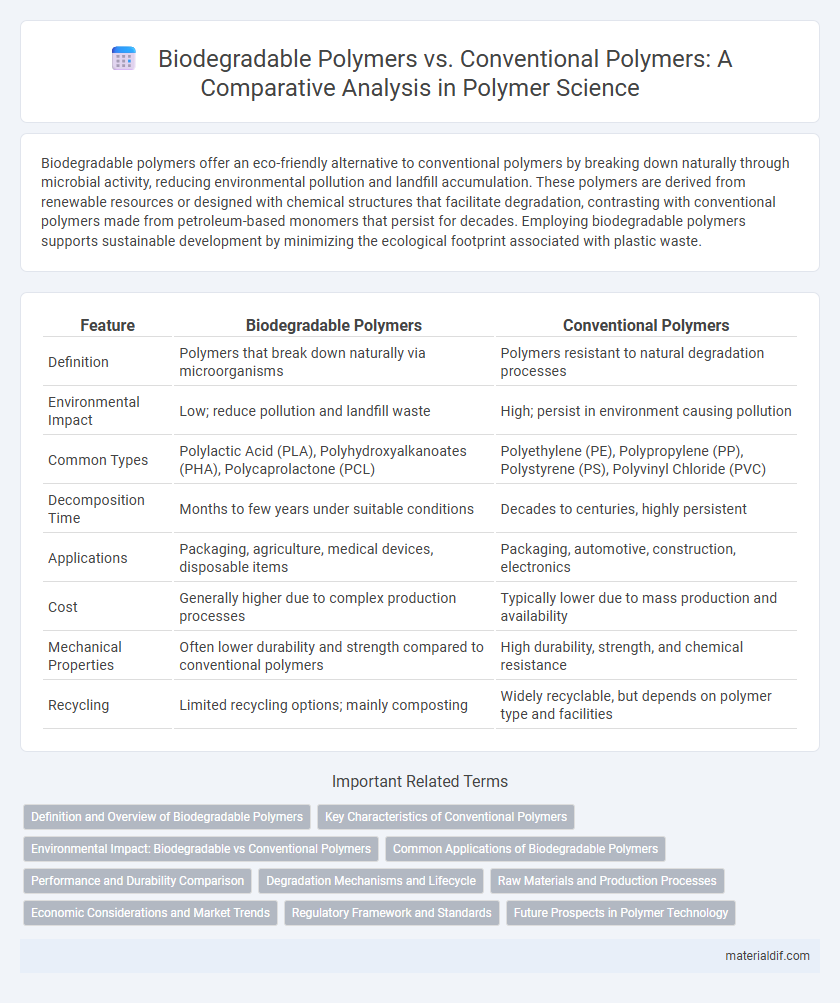

| Feature | Biodegradable Polymers | Conventional Polymers |

|---|---|---|

| Definition | Polymers that break down naturally via microorganisms | Polymers resistant to natural degradation processes |

| Environmental Impact | Low; reduce pollution and landfill waste | High; persist in environment causing pollution |

| Common Types | Polylactic Acid (PLA), Polyhydroxyalkanoates (PHA), Polycaprolactone (PCL) | Polyethylene (PE), Polypropylene (PP), Polystyrene (PS), Polyvinyl Chloride (PVC) |

| Decomposition Time | Months to few years under suitable conditions | Decades to centuries, highly persistent |

| Applications | Packaging, agriculture, medical devices, disposable items | Packaging, automotive, construction, electronics |

| Cost | Generally higher due to complex production processes | Typically lower due to mass production and availability |

| Mechanical Properties | Often lower durability and strength compared to conventional polymers | High durability, strength, and chemical resistance |

| Recycling | Limited recycling options; mainly composting | Widely recyclable, but depends on polymer type and facilities |

Definition and Overview of Biodegradable Polymers

Biodegradable polymers are materials capable of breaking down naturally into water, carbon dioxide, and biomass through microbial action, contrasting with conventional polymers that persist in the environment for decades due to their synthetic nature. These polymers include polylactic acid (PLA), polyhydroxyalkanoates (PHA), and starch-based polymers, widely used in packaging, agriculture, and biomedical applications. Their eco-friendly properties reduce pollution and reliance on fossil fuels, promoting sustainable development in polymer science.

Key Characteristics of Conventional Polymers

Conventional polymers such as polyethylene, polypropylene, and polystyrene are characterized by their high molecular weight, hydrophobicity, and resistance to chemical and biological degradation. These polymers exhibit excellent mechanical strength, thermal stability, and durability, making them ideal for long-lasting applications. However, their persistence in the environment contributes significantly to plastic pollution due to their non-biodegradable nature.

Environmental Impact: Biodegradable vs Conventional Polymers

Biodegradable polymers decompose naturally through microbial activity, significantly reducing long-term environmental pollution compared to conventional polymers, which persist for centuries in landfills and oceans. The breakdown of biodegradable polymers minimizes the accumulation of microplastics, thereby lowering ecological and health risks associated with plastic waste. Conventional polymers, composed primarily of non-renewable petroleum-based materials, contribute extensively to carbon emissions and ecological degradation throughout their lifecycle.

Common Applications of Biodegradable Polymers

Biodegradable polymers are widely used in medical applications such as sutures, drug delivery systems, and tissue engineering due to their ability to break down safely within the body. In agriculture, these polymers serve as mulch films and controlled-release fertilizers that reduce environmental impact compared to conventional polymers. Packaging industries also utilize biodegradable polymers for producing compostable bags and containers, addressing the global demand for sustainable alternatives to conventional plastic products.

Performance and Durability Comparison

Biodegradable polymers typically exhibit lower mechanical strength and reduced durability compared to conventional polymers, limiting their use in high-performance applications. Conventional polymers like polyethylene and polypropylene offer superior resistance to environmental stressors and longer service life due to their stable molecular structures. Advances in biodegradable polymer formulations, such as polylactic acid (PLA) blends and polyhydroxyalkanoates (PHA), aim to enhance performance while maintaining eco-friendly degradation rates.

Degradation Mechanisms and Lifecycle

Biodegradable polymers degrade through hydrolysis, enzymatic action, or microbial activity, breaking down into water, carbon dioxide, and biomass within months to years, minimizing environmental impact. Conventional polymers, composed mainly of long-chain hydrocarbons, resist natural degradation, persisting in ecosystems for decades or centuries due to their chemical stability and high molecular weight. The lifecycle of biodegradable polymers prioritizes rapid decomposition and resource recovery, contrasting with conventional polymers that contribute to long-term pollution and require energy-intensive recycling or landfill disposal.

Raw Materials and Production Processes

Biodegradable polymers are primarily derived from renewable raw materials such as starch, cellulose, and polylactic acid, whereas conventional polymers are synthesized from fossil fuel-based petrochemicals like ethylene and propylene. The production process of biodegradable polymers often involves fermentation or enzymatic polymerization, resulting in materials that break down naturally under environmental conditions. In contrast, conventional polymer manufacturing relies on energy-intensive polymerization techniques such as addition or condensation polymerization, producing durable plastics with limited environmental degradation.

Economic Considerations and Market Trends

Biodegradable polymers are gaining market traction due to growing environmental regulations and consumer demand for sustainable products, despite higher production costs compared to conventional polymers. The global biodegradable polymer market is projected to grow at a CAGR of over 15% from 2024 to 2030, driven by advancements in bio-based materials and government incentives. Conventional polymers dominate due to established supply chains and lower prices, but shifting economic policies and increasing plastic taxes are gradually leveling the competitive landscape.

Regulatory Framework and Standards

Biodegradable polymers are increasingly governed by stringent regulatory frameworks such as the European Union's REACH and the U.S. Environmental Protection Agency's guidelines, which mandate environmental safety and decomposition criteria. Conventional polymers, primarily derived from petrochemicals, face less rigorous biodegradability standards but are subject to regulations targeting toxicity and persistence in ecosystems. Standards like ASTM D6400 and ISO 17088 define compostability and biodegradability requirements, crucial for market acceptance and environmental compliance of biodegradable polymers.

Future Prospects in Polymer Technology

Biodegradable polymers, derived from renewable resources like polylactic acid (PLA) and polyhydroxyalkanoates (PHA), offer promising solutions to plastic pollution challenges by breaking down naturally in the environment. Advances in polymer technology focus on enhancing the mechanical properties, degradation rates, and cost-effectiveness of biodegradable polymers to compete with conventional polymers such as polyethylene (PE) and polypropylene (PP). Future prospects include integrating smart polymer systems and bio-based composites, driving sustainable innovation in packaging, agriculture, and biomedical applications.

Biodegradable Polymers vs Conventional Polymers Infographic

materialdif.com

materialdif.com