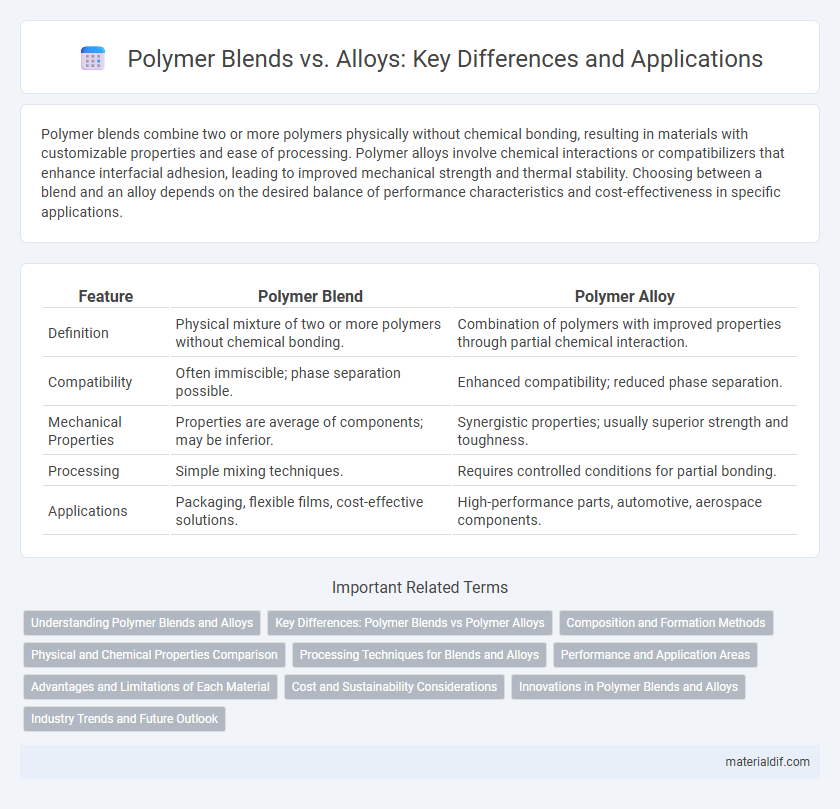

Polymer blends combine two or more polymers physically without chemical bonding, resulting in materials with customizable properties and ease of processing. Polymer alloys involve chemical interactions or compatibilizers that enhance interfacial adhesion, leading to improved mechanical strength and thermal stability. Choosing between a blend and an alloy depends on the desired balance of performance characteristics and cost-effectiveness in specific applications.

Table of Comparison

| Feature | Polymer Blend | Polymer Alloy |

|---|---|---|

| Definition | Physical mixture of two or more polymers without chemical bonding. | Combination of polymers with improved properties through partial chemical interaction. |

| Compatibility | Often immiscible; phase separation possible. | Enhanced compatibility; reduced phase separation. |

| Mechanical Properties | Properties are average of components; may be inferior. | Synergistic properties; usually superior strength and toughness. |

| Processing | Simple mixing techniques. | Requires controlled conditions for partial bonding. |

| Applications | Packaging, flexible films, cost-effective solutions. | High-performance parts, automotive, aerospace components. |

Understanding Polymer Blends and Alloys

Polymer blends combine two or more polymers physically mixed to improve properties without chemical bonding, allowing tailored mechanical strength and flexibility. Polymer alloys involve chemically bonded polymers or copolymers, creating materials with enhanced thermal stability and resistance to degradation. Understanding the distinction between blends and alloys is crucial for optimizing polymer performance in applications like automotive parts, packaging, and electronics.

Key Differences: Polymer Blends vs Polymer Alloys

Polymer blends consist of two or more polymers physically mixed without chemical bonding, resulting in a combination of properties from each component, while polymer alloys involve chemical interactions or compatibilizers that enhance interfacial adhesion and material performance. Polymer blends typically show phase separation, affecting mechanical and thermal properties, whereas polymer alloys exhibit improved homogeneity and compatibility with superior toughness and stability. Understanding the differences in morphology, compatibility, and processing behavior is crucial for selecting polymers tailored to specific applications in industries such as automotive, packaging, and electronics.

Composition and Formation Methods

Blends are physical mixtures of two or more polymers combined without chemical bonding, typically formed by melt blending or solution mixing techniques. Alloys involve polymers chemically combined at the molecular level, often created through copolymerization or reactive blending to achieve enhanced material properties. The key difference lies in blends retaining individual polymer phases, whereas alloys form a single homogeneous phase with altered composition.

Physical and Chemical Properties Comparison

Polymer blends typically exhibit phase separation leading to distinct physical properties from each component, while alloys form a homogeneous mixture with uniform properties. Chemically, blends maintain the individual polymer chains' characteristics, often resulting in varied thermal and mechanical behavior, whereas alloys demonstrate integrated chemical bonds or interactions enhancing overall stability and conductivity. The physical differences include blends showing varied crystallinity and tensile strength, whereas alloys often present consistent density and improved corrosion resistance.

Processing Techniques for Blends and Alloys

Processing techniques for polymer blends typically involve melt mixing and solution blending, where polymers are physically combined without chemical bonding. Alloy processing often requires more advanced methods such as reactive extrusion or compatibilization to facilitate chemical interactions between polymer components, enhancing material properties. Controlling parameters like temperature, shear rate, and mixing time is crucial for both blends and alloys to achieve desired morphology and performance.

Performance and Application Areas

Polymer blends combine two or more polymers physically, optimizing properties like impact resistance and processability for applications in automotive parts and packaging, while alloys involve chemical bonding or co-polymerization, offering enhanced mechanical strength and thermal stability suited for high-performance engineering and electronics. Blends typically provide cost-effective solutions with balanced flexibility and toughness, whereas alloys deliver superior durability and chemical resistance for demanding environments. Selecting between blends and alloys depends on application-specific performance requirements such as temperature tolerance, mechanical load, and environmental exposure.

Advantages and Limitations of Each Material

Polymer blends offer enhanced processability and improved mechanical properties by combining different polymers without chemical bonding, making them cost-effective and easy to manufacture, but they may suffer from phase separation and limited compatibility. Polymer alloys, formed through chemical bonding or cross-linking, provide superior thermal stability and uniform properties, yet they often require more complex synthesis and higher production costs. Selecting between blends and alloys depends on the desired balance of mechanical performance, thermal resistance, and manufacturing feasibility in the application.

Cost and Sustainability Considerations

Polymer blends typically offer cost advantages due to simpler processing and compatibility with existing manufacturing methods, reducing energy consumption and material waste. Alloys, while often providing superior mechanical properties and durability, can incur higher production costs and energy demands from more complex compounding and recycling challenges. Sustainable production leans toward blends when recyclability and lower carbon footprint are prioritized, whereas alloys may require advanced recycling techniques to minimize environmental impact.

Innovations in Polymer Blends and Alloys

Innovations in polymer blends and alloys have led to enhanced material properties by combining polymers at the molecular level, enabling tailored mechanical strength, thermal stability, and chemical resistance. Advanced compatibilizers and novel blending techniques, such as reactive extrusion and nano-enhancement, improve interfacial adhesion and phase dispersion, driving superior performance in automotive, aerospace, and biomedical applications. Emerging research also focuses on sustainable blends using bio-based polymers and recyclable alloys to meet environmental regulations and circular economy goals.

Industry Trends and Future Outlook

Polymer blends dominate industry trends due to their customizable properties and cost-effectiveness, enabling manufacturers to tailor materials for specific applications without complex synthesis. Alloy polymers, while offering superior mechanical strength and thermal stability, face higher production costs and limited scalability, restricting widespread adoption. Future outlooks predict increased integration of nanotechnology to enhance blend compatibility, driving innovative, high-performance polymer materials tailored to demanding industrial requirements.

Blend vs Alloy Infographic

materialdif.com

materialdif.com