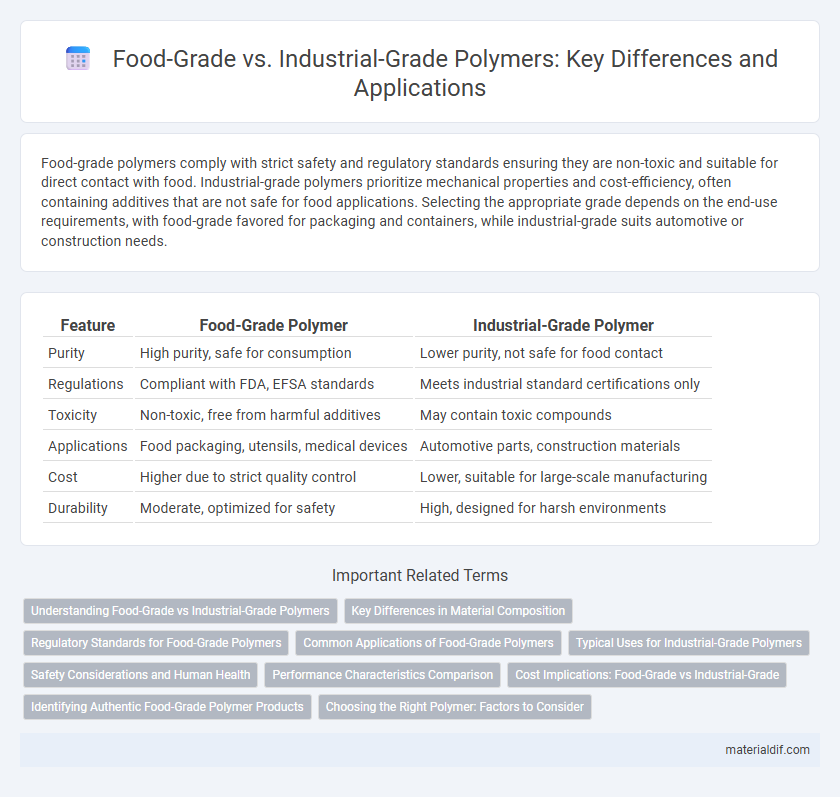

Food-grade polymers comply with strict safety and regulatory standards ensuring they are non-toxic and suitable for direct contact with food. Industrial-grade polymers prioritize mechanical properties and cost-efficiency, often containing additives that are not safe for food applications. Selecting the appropriate grade depends on the end-use requirements, with food-grade favored for packaging and containers, while industrial-grade suits automotive or construction needs.

Table of Comparison

| Feature | Food-Grade Polymer | Industrial-Grade Polymer |

|---|---|---|

| Purity | High purity, safe for consumption | Lower purity, not safe for food contact |

| Regulations | Compliant with FDA, EFSA standards | Meets industrial standard certifications only |

| Toxicity | Non-toxic, free from harmful additives | May contain toxic compounds |

| Applications | Food packaging, utensils, medical devices | Automotive parts, construction materials |

| Cost | Higher due to strict quality control | Lower, suitable for large-scale manufacturing |

| Durability | Moderate, optimized for safety | High, designed for harsh environments |

Understanding Food-Grade vs Industrial-Grade Polymers

Food-grade polymers meet stringent regulatory standards such as FDA and EU regulations to ensure safety, non-toxicity, and suitability for direct contact with food. Industrial-grade polymers, however, prioritize mechanical strength and chemical resistance for applications in packaging, automotive parts, and construction without the necessity for food safety compliance. Key differences lie in formulation, additives, and testing protocols that define their specific use cases in food industry versus industrial manufacturing.

Key Differences in Material Composition

Food-grade polymers are formulated with non-toxic, FDA-compliant additives and lack harmful plasticizers or heavy metals, ensuring safety for direct food contact. Industrial-grade polymers often contain stabilizers, fillers, or plasticizers that enhance mechanical properties but may release contaminants unsuitable for food applications. The primary distinction lies in purity standards and material composition tailored to meet regulatory requirements for ingestion safety in food-grade polymers versus performance optimization in industrial-grade variants.

Regulatory Standards for Food-Grade Polymers

Food-grade polymers comply with strict regulatory standards set by agencies like the FDA and EFSA, ensuring materials are safe for direct food contact and free from harmful contaminants. These polymers undergo rigorous testing for migration limits, toxicity, and allergenicity to meet compliance requirements outlined in regulations such as FDA 21 CFR 177 and EU Regulation 10/2011. Industrial-grade polymers lack these certifications and are typically used for non-food applications where safety standards are less stringent.

Common Applications of Food-Grade Polymers

Food-grade polymers are specifically designed for direct contact with food products, ensuring safety and compliance with FDA and EU regulations. Common applications include packaging materials such as films, containers, and trays, as well as food processing equipment components like seals and gaskets. These polymers often comprise polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET), which provide durability, chemical resistance, and non-toxicity essential for maintaining food quality and hygiene.

Typical Uses for Industrial-Grade Polymers

Industrial-grade polymers are primarily utilized in manufacturing applications such as automotive components, electrical insulation, and packaging materials requiring high durability and chemical resistance. These polymers exhibit enhanced mechanical properties suitable for heavy-duty use, including in construction, machinery parts, and electronic housings. Their robust nature makes them ideal for environments demanding strength, thermal stability, and resistance to harsh chemicals or abrasion.

Safety Considerations and Human Health

Food-grade polymers undergo rigorous testing to meet strict safety standards set by regulatory agencies such as the FDA and EFSA, ensuring they do not leach harmful chemicals into food or beverages. Industrial-grade polymers may contain additives or contaminants unsuitable for human consumption, posing potential health risks such as toxicity or allergen exposure when used in food applications. Selecting food-grade polymers is crucial for applications involving direct contact with consumables to prevent contamination and ensure consumer safety.

Performance Characteristics Comparison

Food-grade polymers are engineered to comply with strict safety and hygiene standards, ensuring non-toxicity, high chemical resistance, and durability under varying temperatures, which makes them suitable for direct contact with consumables. Industrial-grade polymers prioritize mechanical strength, abrasion resistance, and thermal stability to withstand harsh operational environments, often sacrificing purity standards necessary for food applications. Performance characteristics such as permeability, flexibility, and regulatory compliance differ significantly, with food-grade polymers optimized for safety and sensory neutrality, while industrial-grade polymers emphasize robustness and longevity in heavy-duty use.

Cost Implications: Food-Grade vs Industrial-Grade

Food-grade polymers incur higher production costs due to stringent purity standards and regulatory certifications necessary for safe food contact applications. Industrial-grade polymers, while less expensive, often contain additives or impurities unsuitable for consumption but are suitable for non-food-related uses, significantly reducing material and processing expenses. These cost differences impact the selection process depending on the final application requirements and budget constraints.

Identifying Authentic Food-Grade Polymer Products

Food-grade polymers meet strict FDA and EU regulations for non-toxicity and safety in direct food contact, often certified with specific food-grade symbols or documentation. Industrial-grade polymers lack such certifications and may contain additives or contaminants unsuitable for food applications, posing health risks if misused. Verifying authenticity involves checking for compliance labels, third-party testing reports, and supplier traceability to ensure polymer products are genuinely food-grade.

Choosing the Right Polymer: Factors to Consider

Food-grade polymers must meet rigorous safety standards, including FDA and EU regulations, ensuring non-toxicity, chemical inertness, and resistance to food contaminants. Industrial-grade polymers prioritize mechanical strength, thermal stability, and cost-effectiveness for applications such as automotive parts, packaging, or construction materials. Selecting the right polymer depends on compliance requirements, intended use environment, exposure conditions, and potential chemical interactions.

Food-Grade vs Industrial-Grade Infographic

materialdif.com

materialdif.com