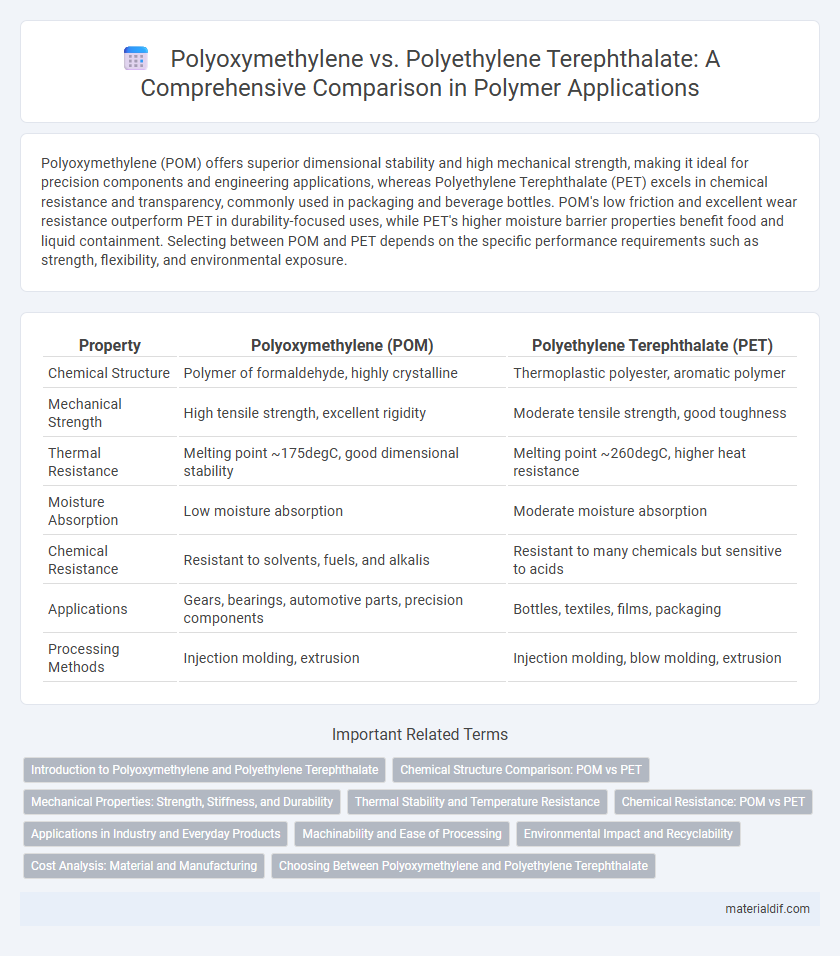

Polyoxymethylene (POM) offers superior dimensional stability and high mechanical strength, making it ideal for precision components and engineering applications, whereas Polyethylene Terephthalate (PET) excels in chemical resistance and transparency, commonly used in packaging and beverage bottles. POM's low friction and excellent wear resistance outperform PET in durability-focused uses, while PET's higher moisture barrier properties benefit food and liquid containment. Selecting between POM and PET depends on the specific performance requirements such as strength, flexibility, and environmental exposure.

Table of Comparison

| Property | Polyoxymethylene (POM) | Polyethylene Terephthalate (PET) |

|---|---|---|

| Chemical Structure | Polymer of formaldehyde, highly crystalline | Thermoplastic polyester, aromatic polymer |

| Mechanical Strength | High tensile strength, excellent rigidity | Moderate tensile strength, good toughness |

| Thermal Resistance | Melting point ~175degC, good dimensional stability | Melting point ~260degC, higher heat resistance |

| Moisture Absorption | Low moisture absorption | Moderate moisture absorption |

| Chemical Resistance | Resistant to solvents, fuels, and alkalis | Resistant to many chemicals but sensitive to acids |

| Applications | Gears, bearings, automotive parts, precision components | Bottles, textiles, films, packaging |

| Processing Methods | Injection molding, extrusion | Injection molding, blow molding, extrusion |

Introduction to Polyoxymethylene and Polyethylene Terephthalate

Polyoxymethylene (POM) is a highly crystalline thermoplastic known for its exceptional stiffness, low friction, and excellent dimensional stability, making it ideal for precision engineering components. Polyethylene Terephthalate (PET) is a widely used polyester resin valued for its high strength, chemical resistance, and recyclability, commonly found in fibers and beverage containers. Both polymers serve distinct industrial applications due to their unique molecular structures and mechanical properties.

Chemical Structure Comparison: POM vs PET

Polyoxymethylene (POM) features a repeating -CH2-O- unit forming a linear, highly crystalline acetal polymer, providing exceptional stiffness and low friction properties. Polyethylene Terephthalate (PET) consists of repeating ester linkages formed by terephthalic acid and ethylene glycol, creating a semi-crystalline aromatic polyester with strong tensile strength and thermal stability. The key structural difference lies in POM's acetal backbone versus PET's aromatic ester backbone, influencing their mechanical performance and chemical resistance.

Mechanical Properties: Strength, Stiffness, and Durability

Polyoxymethylene (POM) exhibits superior mechanical strength and stiffness compared to Polyethylene Terephthalate (PET), making it ideal for precision parts requiring high rigidity and wear resistance. PET offers greater impact resistance and flexibility, providing enhanced durability in applications involving cyclic loading or thermal variations. The choice between POM and PET depends on balancing the need for mechanical robustness against flexibility and environmental stress tolerance.

Thermal Stability and Temperature Resistance

Polyoxymethylene (POM) exhibits superior thermal stability with a melting point around 175degC, making it suitable for applications requiring high temperature resistance. In contrast, Polyethylene Terephthalate (PET) has a melting point near 260degC but begins to degrade at lower temperatures during prolonged exposure. POM's crystalline structure imparts better dimensional stability and resistance to thermal deformation compared to PET, which tends to soften under sustained heat.

Chemical Resistance: POM vs PET

Polyoxymethylene (POM) exhibits superior chemical resistance to a wide range of solvents, including alcohols, hydrocarbons, and dilute acids, making it ideal for applications requiring durability against chemical exposure. Polyethylene Terephthalate (PET) offers moderate resistance but is more susceptible to degradation in strong acids and bases compared to POM. The molecular structure of POM, featuring a stable repeating -CH2O- unit, contributes to its enhanced resistance, whereas PET's ester linkages are prone to hydrolysis under harsh chemical conditions.

Applications in Industry and Everyday Products

Polyoxymethylene (POM) exhibits exceptional stiffness, low friction, and high dimensional stability, making it ideal for precision mechanical parts such as gears, bearings, and automotive components. Polyethylene Terephthalate (PET) is widely used in packaging, especially for beverage bottles and food containers, due to its excellent chemical resistance and clarity. While POM excels in durable industrial applications requiring strength and abrasion resistance, PET dominates in packaging and textile industries where lightweight, transparency, and recyclability are crucial.

Machinability and Ease of Processing

Polyoxymethylene (POM) exhibits superior machinability compared to Polyethylene Terephthalate (PET), owing to its high crystallinity and low friction properties, which reduce tool wear and improve surface finish. POM processes efficiently via injection molding and machining techniques such as turning and milling, whereas PET requires more precise temperature control due to its susceptibility to hydrolysis and thermal degradation. The ease of processing POM makes it ideal for producing complex, high-tolerance mechanical parts, while PET is typically favored for applications demanding excellent chemical resistance and dimensional stability.

Environmental Impact and Recyclability

Polyoxymethylene (POM) exhibits a lower environmental impact due to its higher durability and longer lifespan compared to Polyethylene Terephthalate (PET), which often results in reduced waste generation. PET is widely recycled worldwide, benefiting from established recovery programs and a high recycling rate, making it more favorable in circular economy models. The recyclability of POM is limited by its chemical structure and scarcity of recycling facilities, contributing to higher challenges in sustainable disposal and reuse.

Cost Analysis: Material and Manufacturing

Polyoxymethylene (POM) offers superior mechanical properties and dimensional stability at a higher raw material cost compared to Polyethylene Terephthalate (PET), which is more economical for large-scale production. Manufacturing POM involves more complex processing conditions, including precise temperature control and moisture sensitivity, increasing production expenses relative to PET's more straightforward extrusion and injection molding processes. Overall, PET's lower material and processing costs make it favorable for cost-sensitive applications, whereas POM is preferred when performance justifies the premium.

Choosing Between Polyoxymethylene and Polyethylene Terephthalate

Polyoxymethylene (POM) offers superior mechanical strength, stiffness, and dimensional stability, making it ideal for precision engineering applications requiring low friction and high wear resistance. Polyethylene terephthalate (PET) excels in chemical resistance, thermal stability, and transparency, often preferred for packaging and textile industries. Selecting between POM and PET depends on application-specific factors such as load-bearing requirements, exposure to chemicals, and the need for clarity or flexibility.

Polyoxymethylene vs Polyethylene Terephthalate Infographic

materialdif.com

materialdif.com